CustomModAddict

Limp Gawd

- Joined

- Sep 2, 2010

- Messages

- 184

I decided to do a complete system mod for my 13 year old son who lives in Georgia. I could have just threw some old system together or bought an alienware or other pre-made system for him. But I wanted something special for him, I wanted something built by my hands and my ideas. Something he could be proud of, "My Dad built this for me".

So we are starting with Chyang Fun A320 case (stock photo pictured below) these were popular with certain modders a few years back. I wish I would have bought more of them, this is my last one. I have the silver one.

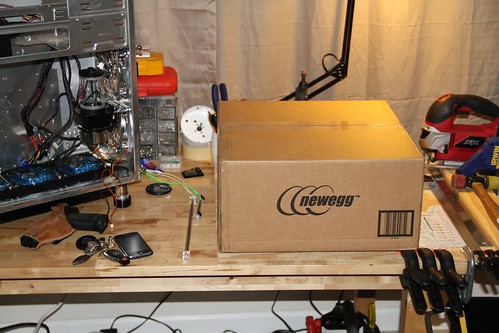

Just placed the final order for all the hardware, as soon as it gets here I can really start getting this project done.

System Specs:

MB ASUS P7P55D-E PRO P55 R

ASUS GTX 470 GPU

CPU INTEL CORE I5 760 2.8

2Gx2 GSKILL PC1600 RAM

ASUS DRW-24B1ST/BLK/B/AS Black SATA 24X DVD Burner

Western Digital Caviar Blue 640GB 7200 RPM SATA 3.0Gb/s 3.5" Internal Hard Drive

Kingwin LAZER Performance Series SLI Ready 850W Modular Power Supply

EK GeForce 470 GTX VGA Liquid Cooling Block

EK Supreme HF Universal CPU Liquid Cooling Block - Rev 2 -

Aerocool Shark Blue Edition 120mm x 25mm High Air Pressure Fan w/ Blue LEDs

AeroCool 120mm Turbine 1000 Fan - SILVER

Mod/Smart 20 Station LED Board - Base w/ 20x LEDs - Black Base / Blue Switch / Blue LEDs

Blue Illuminated Bulgin Style "Momentary" Vandal Switch - 22mm - Black Housing - Ring Illumination

Red Illuminated Bulgin Style "Momentary" Vandal Switch - 16mm - Black Housing - Dot Illumination

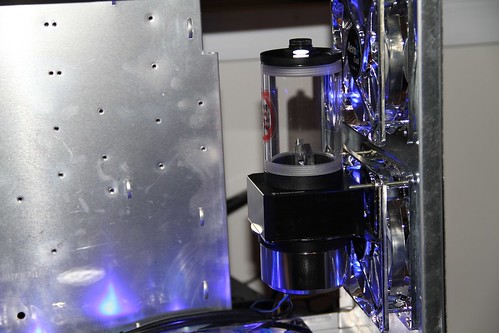

Koolance PMP-450 with Pump Reservoir Base and 150mL Reservoir Tube.

360 Radiator

MNPCTech Black Anodized Handles

MNPCTech Black Anodized Feet

Design Plans:

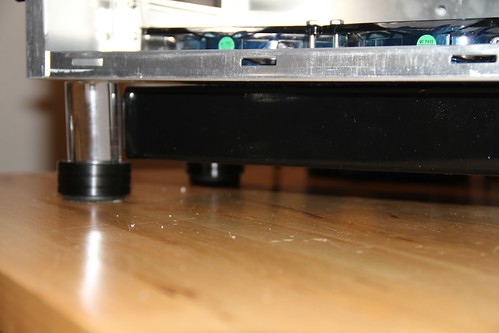

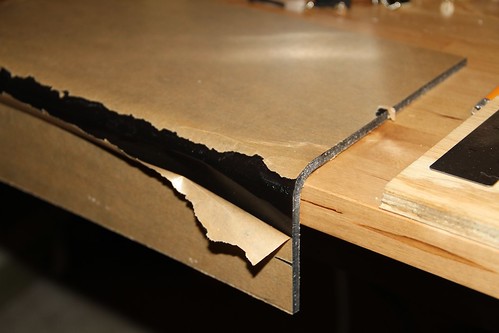

Going to mod and install radiator to bottom of case, Install custom fabricated illuminated case feet, Lazer cut a new acrylic front panel, Custom fabricate interior panels, Custom paint, fabricate interior acrylic parts. Design will be a black with blue illumination.

Well keep on the look out for the next few weeks for updates and plenty of pictures...

So we are starting with Chyang Fun A320 case (stock photo pictured below) these were popular with certain modders a few years back. I wish I would have bought more of them, this is my last one. I have the silver one.

Just placed the final order for all the hardware, as soon as it gets here I can really start getting this project done.

System Specs:

MB ASUS P7P55D-E PRO P55 R

ASUS GTX 470 GPU

CPU INTEL CORE I5 760 2.8

2Gx2 GSKILL PC1600 RAM

ASUS DRW-24B1ST/BLK/B/AS Black SATA 24X DVD Burner

Western Digital Caviar Blue 640GB 7200 RPM SATA 3.0Gb/s 3.5" Internal Hard Drive

Kingwin LAZER Performance Series SLI Ready 850W Modular Power Supply

EK GeForce 470 GTX VGA Liquid Cooling Block

EK Supreme HF Universal CPU Liquid Cooling Block - Rev 2 -

Aerocool Shark Blue Edition 120mm x 25mm High Air Pressure Fan w/ Blue LEDs

AeroCool 120mm Turbine 1000 Fan - SILVER

Mod/Smart 20 Station LED Board - Base w/ 20x LEDs - Black Base / Blue Switch / Blue LEDs

Blue Illuminated Bulgin Style "Momentary" Vandal Switch - 22mm - Black Housing - Ring Illumination

Red Illuminated Bulgin Style "Momentary" Vandal Switch - 16mm - Black Housing - Dot Illumination

Koolance PMP-450 with Pump Reservoir Base and 150mL Reservoir Tube.

360 Radiator

MNPCTech Black Anodized Handles

MNPCTech Black Anodized Feet

Design Plans:

Going to mod and install radiator to bottom of case, Install custom fabricated illuminated case feet, Lazer cut a new acrylic front panel, Custom fabricate interior panels, Custom paint, fabricate interior acrylic parts. Design will be a black with blue illumination.

Well keep on the look out for the next few weeks for updates and plenty of pictures...

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)