Dangerden Tower 21 Build

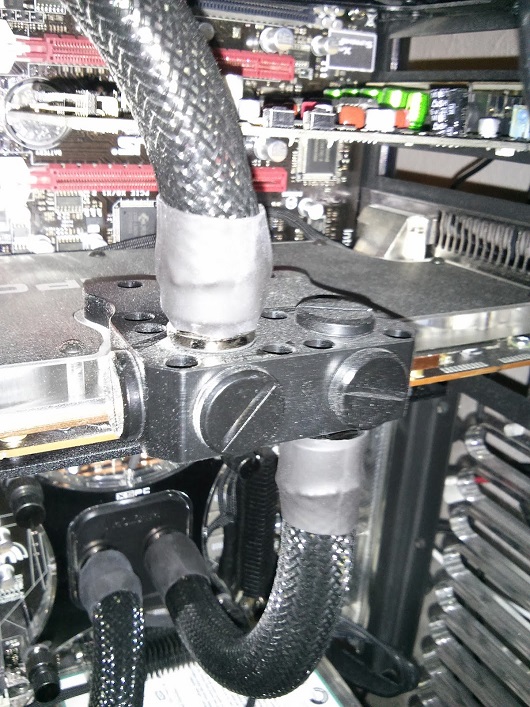

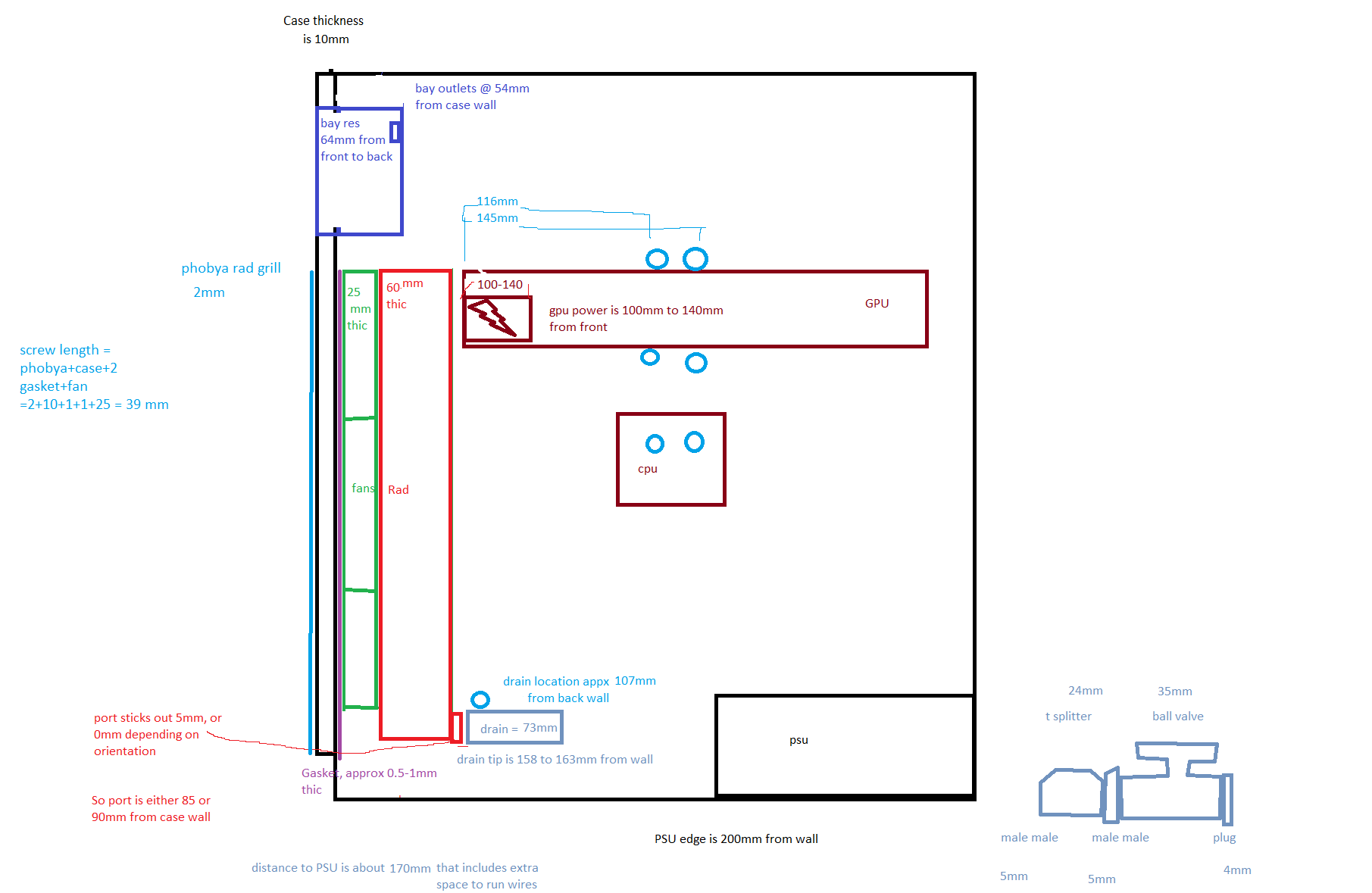

Hi pals, in attempts to defeat my executive dysfunction, I am starting a log. I purchased MOST of these parts in the middle of the pandemic in 2020 and 2021, and have been running this computer on air since, despite having water blocks and radiators laying around my house the entire time. The goal of this build is to fit a modern watercooled gaming system inside of a "mid size" Dangerden Tower 21. I have "mid size" in quotes, because modern mid size cases are not this small.

Admittedly, I started writing the content for this work log almost a month ago, so many of these photos and posts are not exactly current.

Parts:

5900x with XSPC Raystorm Edge

6900xt with EK Classic 6800/6900xt waterblock in nickel

Patriot DDR4 b-die ram

Asus B550-F

Fractal Design Ion platinum 850w

Western Digital Blue 2 tb NVME

western digital blue 4 tb SSD

Intel x25-m 160gb SSD (lol vintage)

Inte SSD 730 480gb (lol vintage)

Noctual a12x25 fans

EK XE360 Radiator

Monsoon Series Two D5 Dual Bay Reservoir

Phanteks, Barrow fittings

Tygon A-60-G tubing

Phobya 360mm radiator grille

Demciflex filter

XSPC temperature stop plug

Hi pals, in attempts to defeat my executive dysfunction, I am starting a log. I purchased MOST of these parts in the middle of the pandemic in 2020 and 2021, and have been running this computer on air since, despite having water blocks and radiators laying around my house the entire time. The goal of this build is to fit a modern watercooled gaming system inside of a "mid size" Dangerden Tower 21. I have "mid size" in quotes, because modern mid size cases are not this small.

Admittedly, I started writing the content for this work log almost a month ago, so many of these photos and posts are not exactly current.

Parts:

5900x with XSPC Raystorm Edge

6900xt with EK Classic 6800/6900xt waterblock in nickel

Patriot DDR4 b-die ram

Asus B550-F

Fractal Design Ion platinum 850w

Western Digital Blue 2 tb NVME

western digital blue 4 tb SSD

Intel x25-m 160gb SSD (lol vintage)

Inte SSD 730 480gb (lol vintage)

Noctual a12x25 fans

EK XE360 Radiator

Monsoon Series Two D5 Dual Bay Reservoir

Phanteks, Barrow fittings

Tygon A-60-G tubing

Phobya 360mm radiator grille

Demciflex filter

XSPC temperature stop plug

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)