StryderxX

[H]ard|Gawd

- Joined

- Jun 22, 2006

- Messages

- 1,730

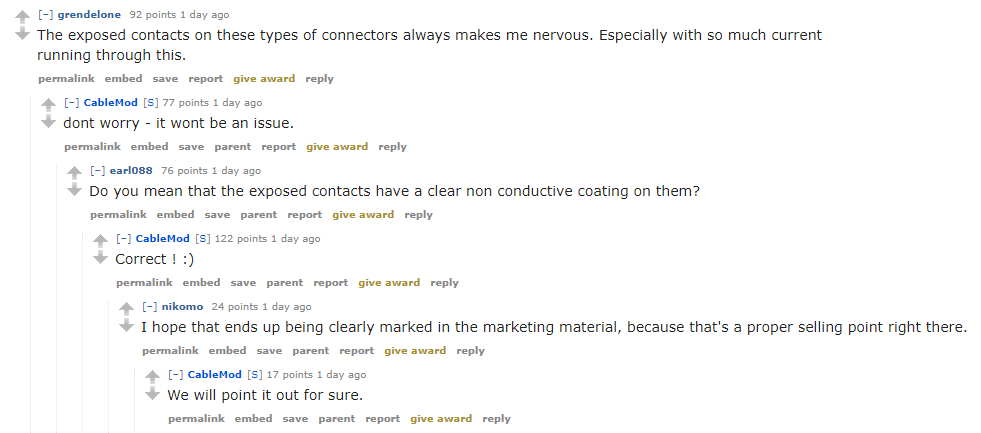

You'll need to install a Tesla Powerwall. The local grid might not supply enough wattage. /sI was thinking a 10ft extension cord and plug it onto a 110 wall outlet, just bypass the PSU, I am sure their next card may need 220 or 221 what ever it takes.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)