WheresWaldo

Limp Gawd

- Joined

- Dec 7, 2004

- Messages

- 182

I just got my Cooler Master MasterCase 5 Pro and I have a lot of time before I have all the parts to build up my PC. So, I asked on the CoolerMaster forum if part of "Make it your own" included releasing 3D models for easier modding. I got no response.

These are not scans of the original parts converted to solid models, they are recreations from scratch based on measurements of the actual parts. They are designed with a view to home printing replacements. You could also use a 3D print service such as Sculpteo or Ponoko, etc.

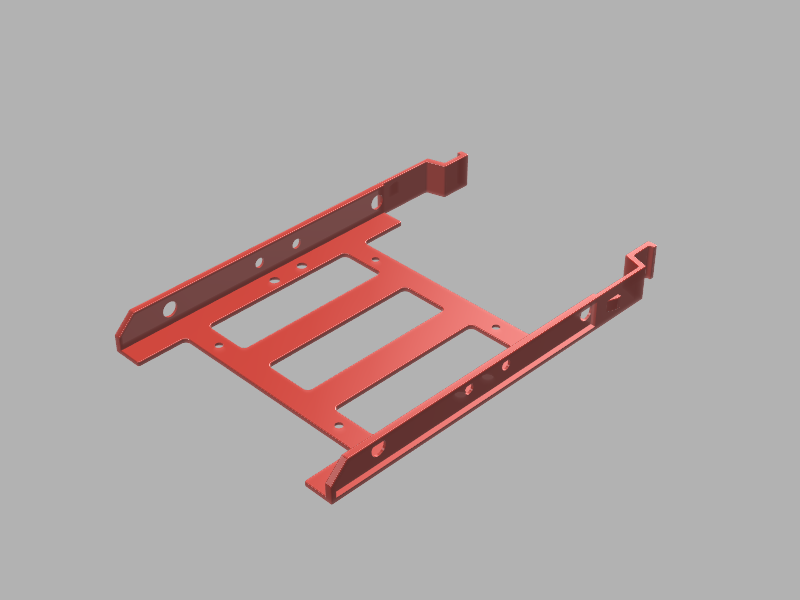

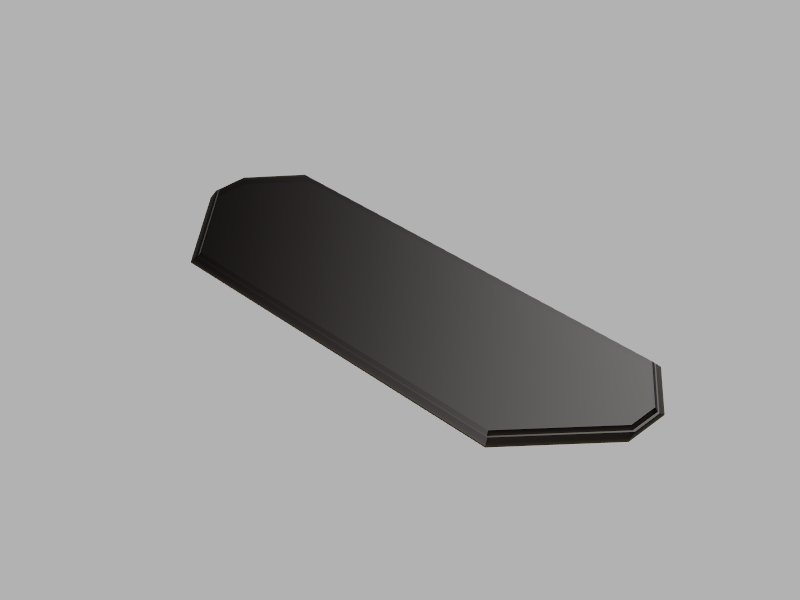

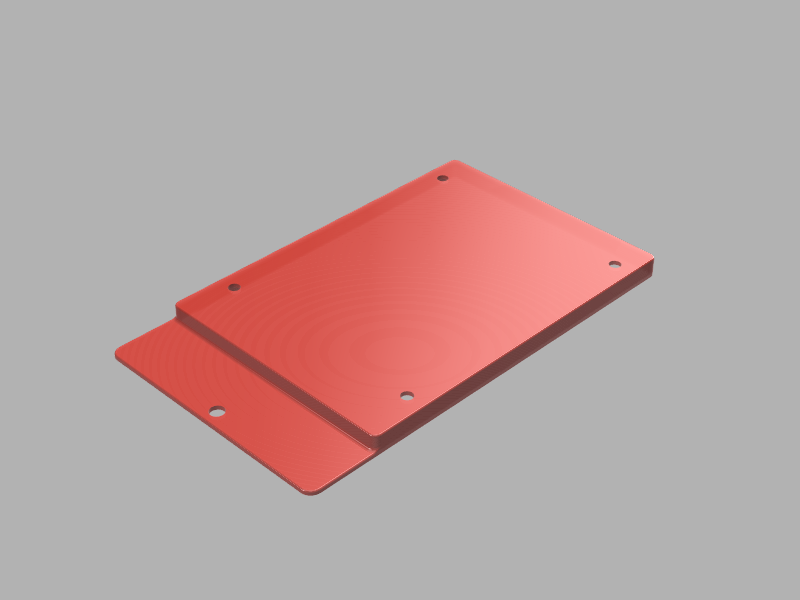

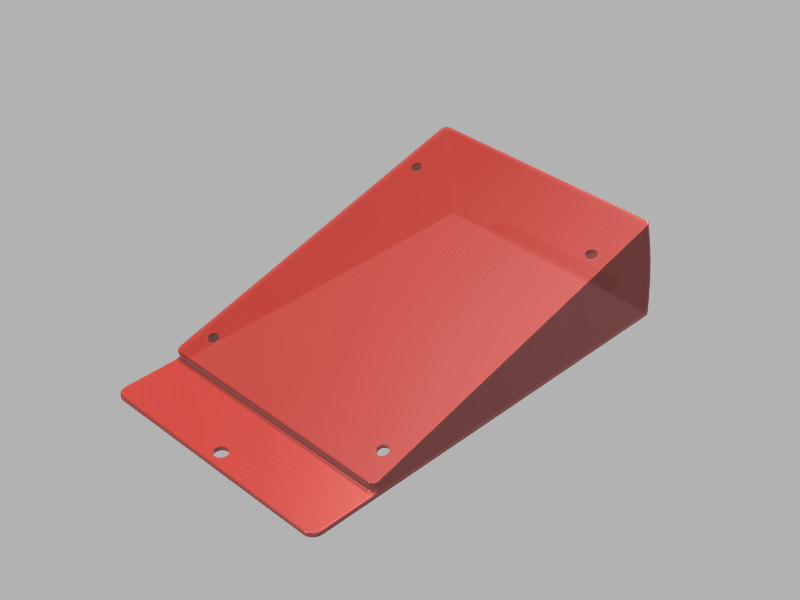

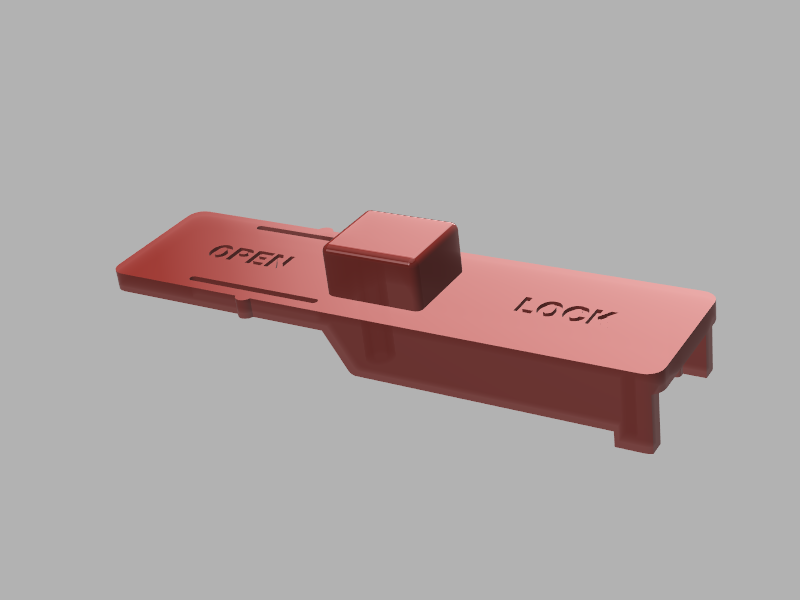

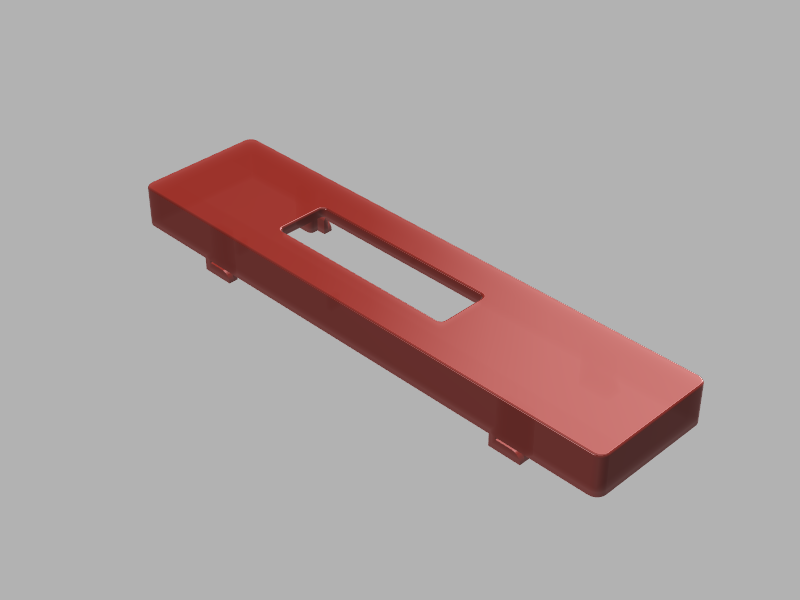

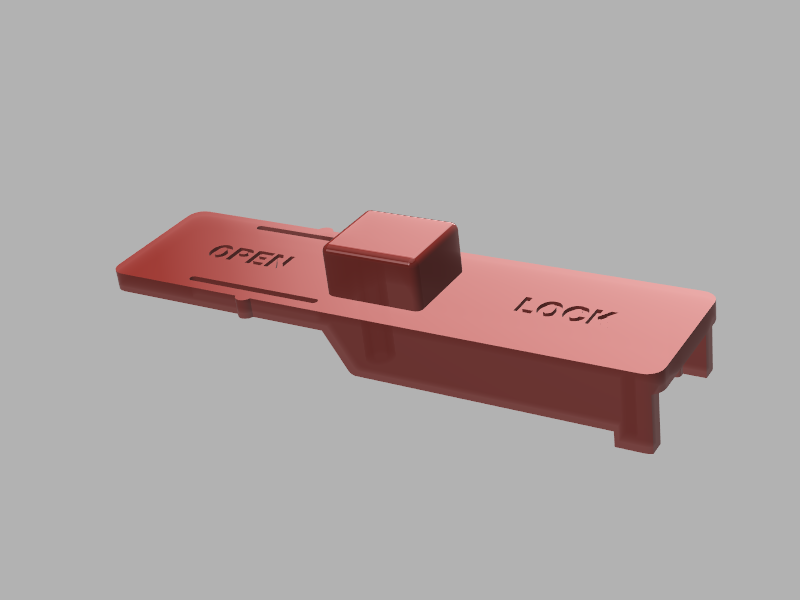

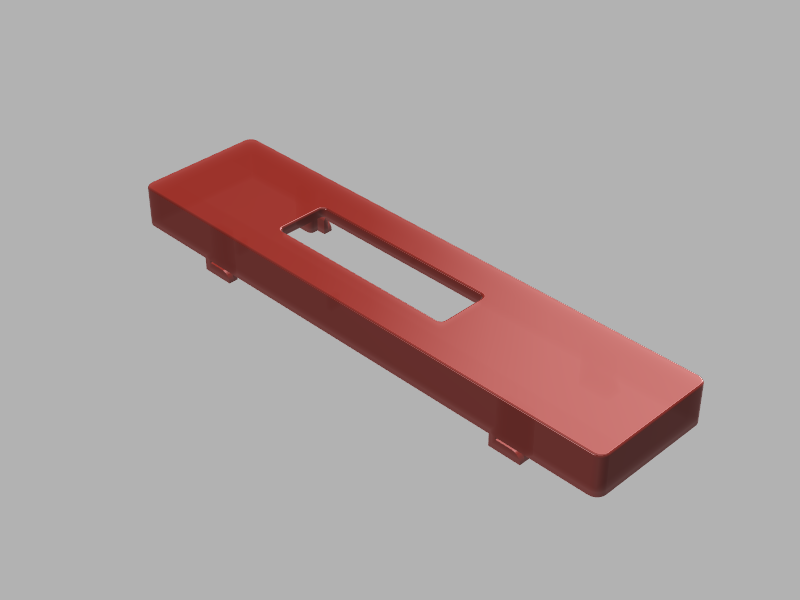

I decided to take apart my case and start to model the parts myself by reverse engineering the dimensions. Mind you I have not printed any of these parts myself, but I did design them so they can be printed on a consumer 3D printer. I have uploaded a couple of models to Thingiverse. I have included STEP files for those that want to further mod the parts themselves. Here are a couple of quick renders.

As you can see below the first parts modeled so far are the slide lock mechanism for the optical drive bays. They should be drop in replacements.

The models are located here:

MasterCase 5 Drive Bay Slide Lock Insert by WheresWaldo

MasterCase 5 Drive Lock Outer Shell by WheresWaldo

As time permits, I will try to model the other exterior parts for self printing.

Mods: If this does not belong in Worklogs feel free to move it to whatever forum is appropriate.

These are not scans of the original parts converted to solid models, they are recreations from scratch based on measurements of the actual parts. They are designed with a view to home printing replacements. You could also use a 3D print service such as Sculpteo or Ponoko, etc.

I decided to take apart my case and start to model the parts myself by reverse engineering the dimensions. Mind you I have not printed any of these parts myself, but I did design them so they can be printed on a consumer 3D printer. I have uploaded a couple of models to Thingiverse. I have included STEP files for those that want to further mod the parts themselves. Here are a couple of quick renders.

As you can see below the first parts modeled so far are the slide lock mechanism for the optical drive bays. They should be drop in replacements.

The models are located here:

MasterCase 5 Drive Bay Slide Lock Insert by WheresWaldo

MasterCase 5 Drive Lock Outer Shell by WheresWaldo

As time permits, I will try to model the other exterior parts for self printing.

Mods: If this does not belong in Worklogs feel free to move it to whatever forum is appropriate.

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)