Zarathustra[H]

Extremely [H]

- Joined

- Oct 29, 2000

- Messages

- 38,858

Hey all,

I am plotting the flow for a new water loop, and I could use some [H] hive mind input.

I have an Alphacool XT45 420mm radiator, I am looking to repurpose into the new loop.

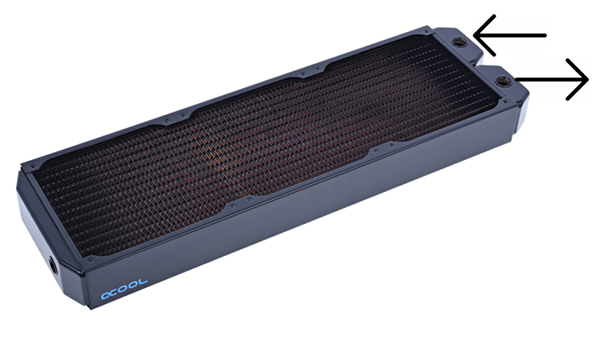

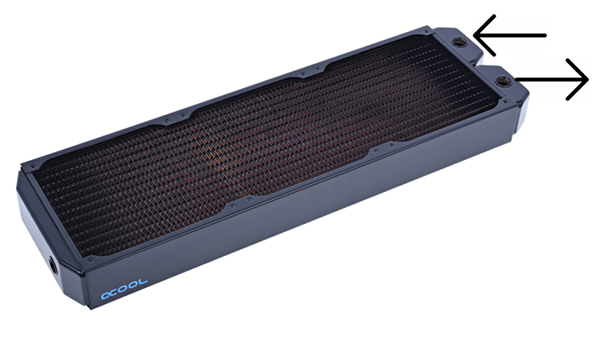

Normally one would use the following ports as in and out:

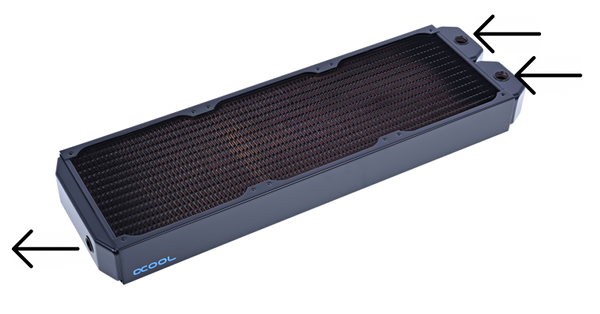

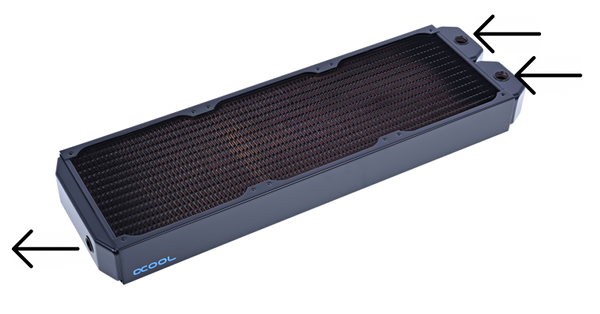

Is there any reason not to do something like this?

It would make my routing a lot simpler if this isn't a problem, but if it does result in issues, I may have to figure something else out.

Appreciate any input.

I am plotting the flow for a new water loop, and I could use some [H] hive mind input.

I have an Alphacool XT45 420mm radiator, I am looking to repurpose into the new loop.

Normally one would use the following ports as in and out:

Is there any reason not to do something like this?

It would make my routing a lot simpler if this isn't a problem, but if it does result in issues, I may have to figure something else out.

Appreciate any input.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)