Wasupwitdat

n00b

- Joined

- May 9, 2013

- Messages

- 22

I have a pretty good rig now

but I also have the itch. I just can't seem to get r done.

After I spend tons of money getting my computer one way I see things the folks post on forums and I end up dissatisfied with what I've accomplished so far.

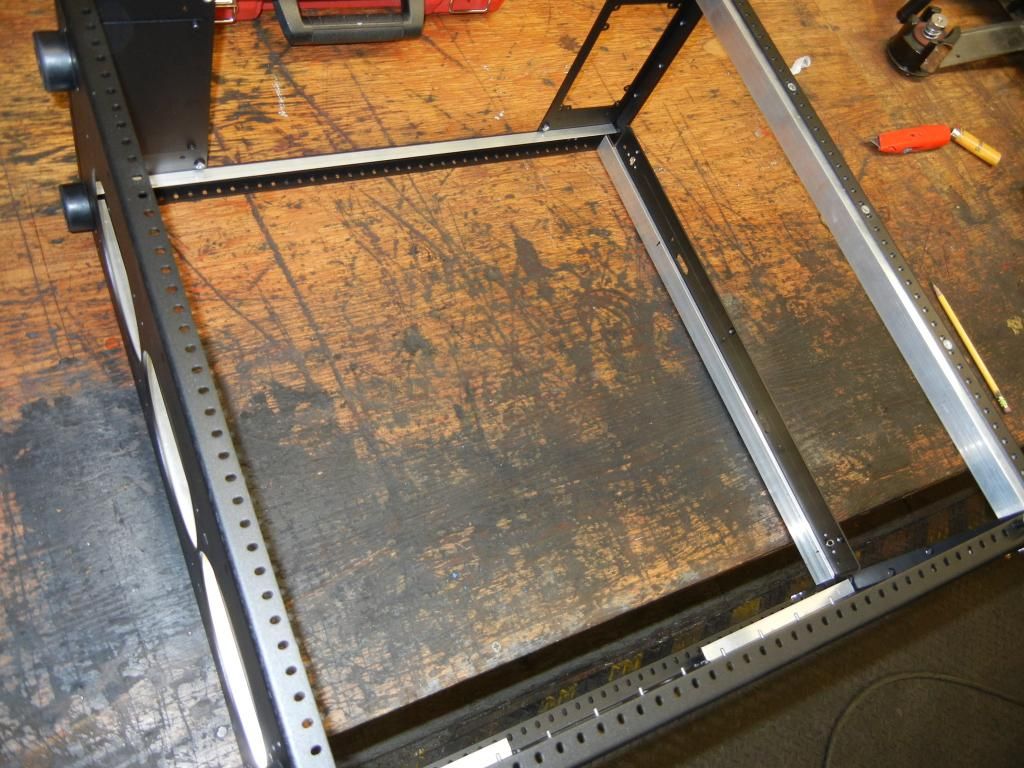

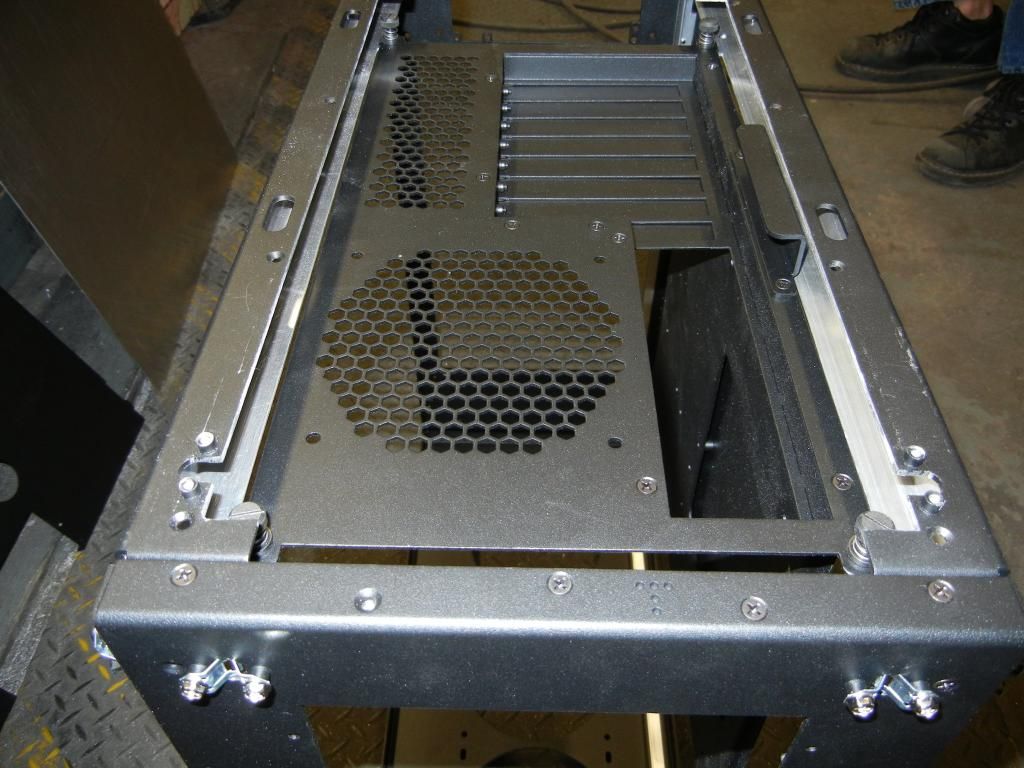

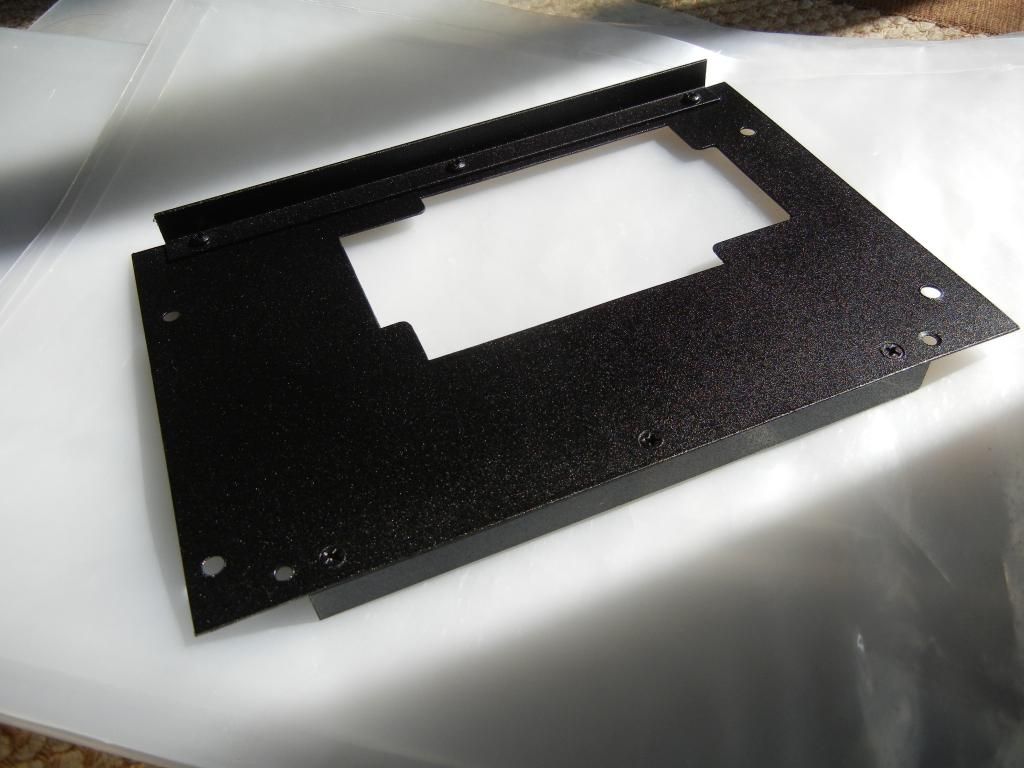

So I bought a Caselabs Merlin SM8. I had an idea and I put it on paper.

but I also have the itch. I just can't seem to get r done.

After I spend tons of money getting my computer one way I see things the folks post on forums and I end up dissatisfied with what I've accomplished so far.

So I bought a Caselabs Merlin SM8. I had an idea and I put it on paper.

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)