N4CR

Supreme [H]ardness

- Joined

- Oct 17, 2011

- Messages

- 4,947

I choose Intel because they are perfect and always work, they are faultless. Amd is peasant junk

Buy my Intel shares btw

Buy my Intel shares btw

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

I don't recall having any issues with those, stock coolers, or water block clips.At least it wasn't like Socket 462 where you had to heave your entire body weight on the retention spring and risk slipping and punching a hole straight through the motherboard, or at bare minimum, ripping chunks and components off of it.

I don't recall having any issues with those, stock coolers, or water block clips.

LMAO. OMG this was the scariest thing dealing with that socket. I've never applied so much pressure using a flat head screwdriver in my life.

Once it was on it was on. There was no IHS either so if you got that CPU to boot it was an act of God considering the amount of pressure applied to the CPU package.

I don't recall having any issues with those, stock coolers, or water block clips.

Companies started selling copper shims for Socket 462 CPUs because of people cracking dies or chipping the corners that resulted in a dead CPU. I still don't know why AMD opted to not have an IHS on that generation, when the K6 before it and the Athlon 64 after it did.

I'd argue you've never installed a Socket 462 CPU, or forgot how hard it was. You can still punch "amd socket 462 cracked cpu" in Google today and see threads from 20 years ago about people cracking their Athlons, Durons and Semprons because of the garbage spring and latch mechanism. Even someone earlier in the thread said they had the same issue. I've built hundreds of Socket 462 machines, it was very much a problem, even if you were as careful as possible.

Companies didn't start selling metal shims for Socket 462 CPUs for no reason. I still have one in my parts bins somewhere.

Or god forbid the “I slammed my screwdriver into the MB when it slipped off the latch and now my board is dead” crowd. That managed to somehow not damage the CPU to only destroy the board instead.Companies started selling copper shims for Socket 462 CPUs because of people cracking dies or chipping the corners that resulted in a dead CPU. I still don't know why AMD opted to not have an IHS on that generation, when the K6 before it and the Athlon 64 after it did.

I'd argue you've never installed a Socket 462 CPU, or forgot how hard it was. You can still punch "amd socket 462 cracked cpu" in Google today and see threads from 20 years ago about people cracking their Athlons, Durons and Semprons because of the garbage spring and latch mechanism. Even someone earlier in the thread said they had the same issue. I've built hundreds of Socket 462 machines, it was very much a problem, even if you were as careful as possible.

Companies didn't start selling metal shims for Socket 462 CPUs for no reason. I still have one in my parts bins somewhere.

Owned about 5 Athlons back in the day in my Soyo Dragon MOBOs and remounted them countless of times, no issues what so ever. Didn't have problems with 386-P5 chips while getting my AS in computers and electronics back in 96 either. I was more worried about connecting AT power, or jumpers wrong. I remember shims being sold and ,maybe, a thread about them on Directron, still don't recall them being widely used.Companies started selling copper shims for Socket 462 CPUs because of people cracking dies or chipping the corners that resulted in a dead CPU. I still don't know why AMD opted to not have an IHS on that generation, when the K6 before it and the Athlon 64 after it did.

I'd argue you've never installed a Socket 462 CPU, or forgot how hard it was. You can still punch "amd socket 462 cracked cpu" in Google today and see threads from 20 years ago about people cracking their Athlons, Durons and Semprons because of the garbage spring and latch mechanism. Even someone earlier in the thread said they had the same issue. I've built hundreds of Socket 462 machines, it was very much a problem, even if you were as careful as possible.

Companies didn't start selling metal shims for Socket 462 CPUs for no reason. I still have one in my parts bins somewhere.

Although I do remember that happening to a few folks because they didn't have thermal protection back then.

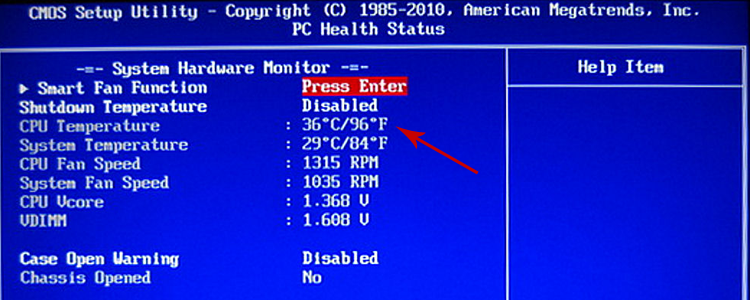

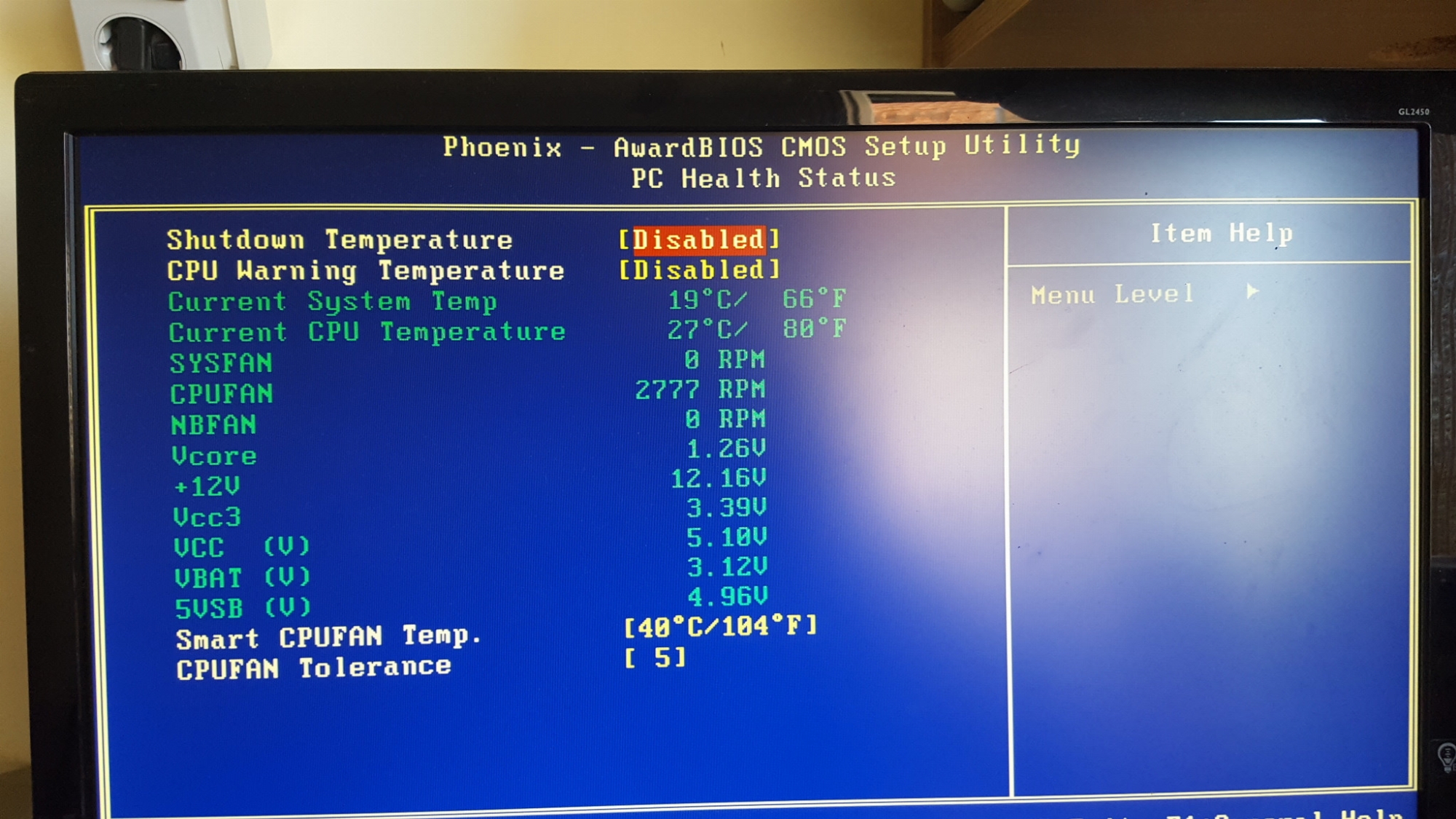

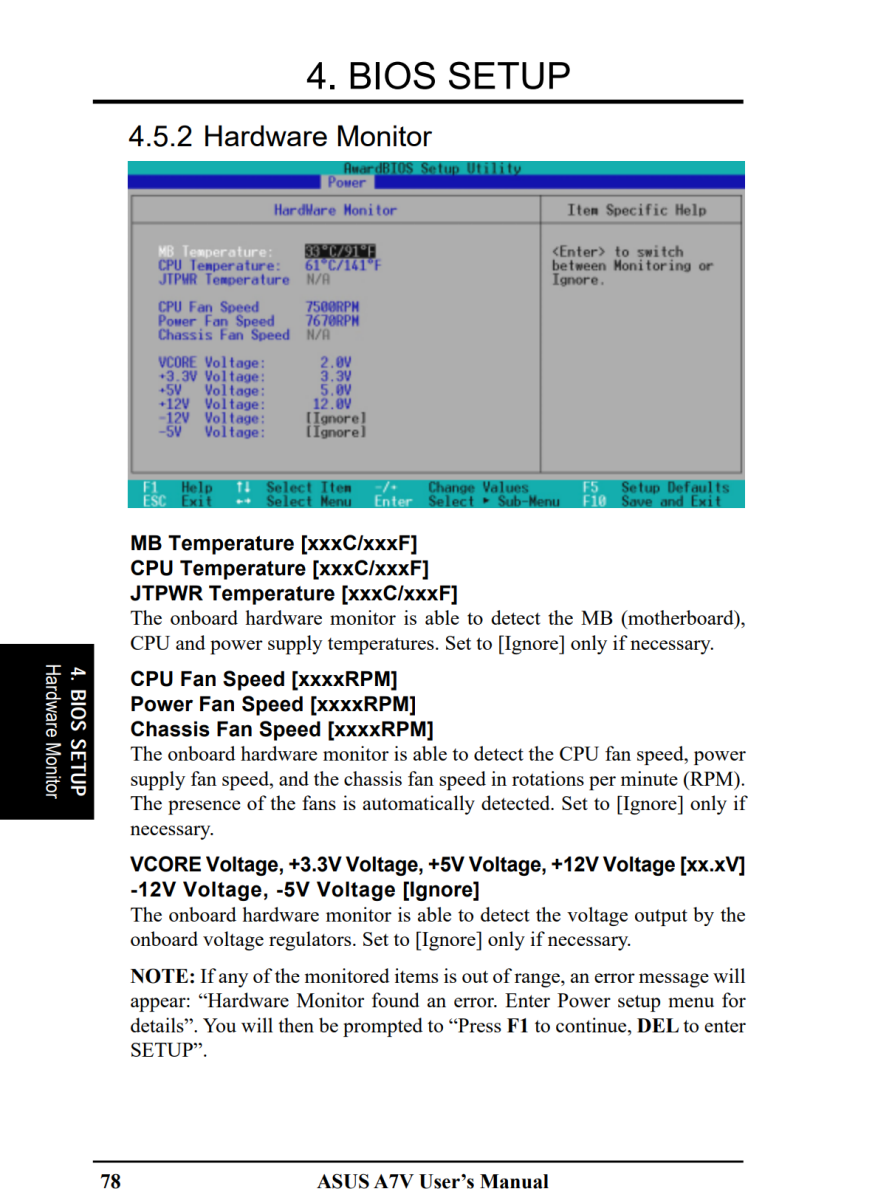

Unfortunately in the event of a heatsink falling off, the chip will die in a near instant!While the CPU did not have thermal protection, motherboards usually had thermal protection. Unfortunately, 99% of the time it was disabled by default, you had to manually go in and specify a thermal warning temperature and thermal shutdown temperature. I always made sure to turn both of these on because customers would never clean or perform regular maintenance on their machines. The CPU heatsink would invariably get 100% plugged, or the fan would fail and at the machine shutting off spontaneously would force them to do something to fix it.

Motherboard thermal protection existed at least as far back as Socket 7.

While the CPU did not have thermal protection, motherboards usually had thermal protection. Unfortunately, 99% of the time it was disabled by default, you had to manually go in and specify a thermal warning temperature and thermal shutdown temperature. I always made sure to turn both of these on because customers would never clean or perform regular maintenance on their machines. The CPU heatsink would invariably get 100% plugged, or the fan would fail and at the machine shutting off spontaneously would force them to do something to fix it.

Motherboard thermal protection existed at least as far back as Socket 7.

My Abit socket A boards had a cpu temp thermistor in the middle of the socket. That was it.I have an aging memory now, but I do not remember any thermal protection for those Athlons. If that HS came off while it was running, it fried. The first boards didn't even have a temp sensor, but that was added later. However don't remember that being included in any protection/prevention. It was just a way to read a CPU temp.

The first boards didn't even have a temp sensor, but that was added later.

However don't remember that being included in any protection/prevention. It was just a way to read a CPU temp.

I wasn't speaking about anything other than Socket-A, specifically some of the very first boards. However as I said that's been quite a while ago.Not true at all. Motherboard temp sensors go back almost a decade before even Socket 462.

Most definitely existed, you just never looked for it.

Could just 3D print something like that.Thermalright to the rescue!

https://www.techpowerup.com/forums/...ector-frame-for-alder-lake-processors.294092/

That looks like Al and considering the cost, is quite remarkable. I certainly could never machine something for that price!Could just 3D print something like that.

Yea didn't catch the price at first. $6 bucks is pretty cheap for a solid AL part like that. It is probably stamped unless this is going to be a stupid low volume item.That looks like Al and considering the cost, is quite remarkable. I certainly could never machine something for that price!

It's probably molded, polished, then anodized. way cheaper that way. You get a lot less waste too.That looks like Al and considering the cost, is quite remarkable. I certainly could never machine something for that price!

Unfortunately in the event of a heatsink falling off, the chip will die in a near instant!

As we've all seen many times LOL!

Could just 3D print something like that.

That's good to know. I was worried that without a heatspreader or heatsink the semiconductor die would rapidly develop hotspots that might burn before a temperature sensor might register.Missed this. Yes, this will happen on boards with no thermal protection enabled/available. I have saved many Socket 462 CPUs with motherboard based thermal protection though. I've tested removing the heatsink a few times with crappy CPUs, motherboard thermal protection will shut the board off near instantly when the heatsink is removed or compromised and lets the temperature pass the set threshold. My own Athlon XP 3200+ rig back in the day was also saved many times when the fan failed while I was away, and those crappy high RPM fans failed quite a lot.

That's good to know. I was worried that without a heatspreader or heatsink the die would very rapidly develop hotspots that might burn before a temperature sensor might even register.

Oh.. i was assuming it was using an on-die sensor. What you described makes me even more worried.Depends on the motherboard and how the thermistor was situated. The best ones I've seen had them on a bit of spring loaded flexible ribbon cable directly under the CPU die in the middle of the socket so they pressed up against the bottom of the CPU. Most of them had the thermistor on the motherboard in the middle of the socket though. But in either case, it gets hotter than the blazes of hell in a hurry under there.

Wouldn't you have to lap the CPU while it's in some kind of fake socket that replicates the tension it's under while installed?I watercool and lap both cpu and block for every new install.