I've decided to go back to watercooling after many years.

This time I'm using distilled water and dyes rather than all-in-one pre-mix. I'd like to avoid corrosion resulting from mixed metals coming into contact with water. There are many threads on the topic but they almost all simply say that distilled water is great and you'll be fine if you simply avoid mixed metals and it's a waste of cash to get anti-corrosives. Seems reasonable, but how do you avoid mixed metals?.

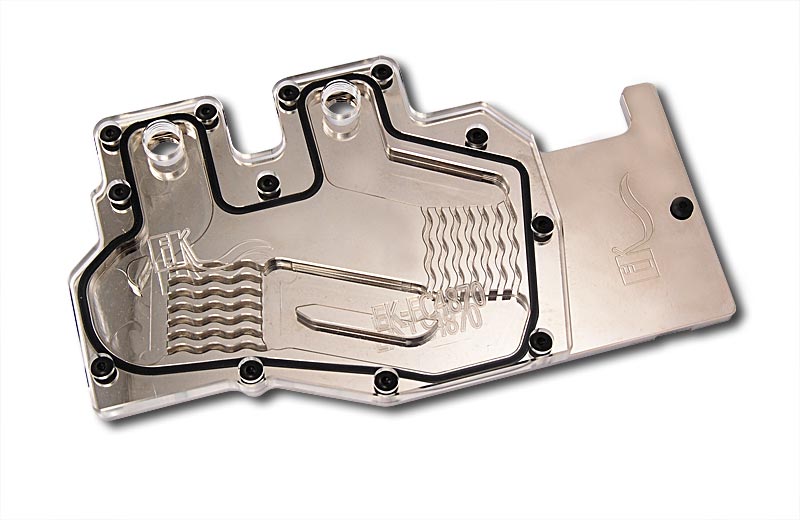

My blocks are all copper as is my radiator, but the fittings I'm using aren't copper. Seems to me that the fittings are exposed to the water just as much as the water blocks, meaning my loop is mixed metal. In fact, given that few fittings are copper as it's a fairly soft metal, this means almost everyone with copper blocks is going to have a mixed metal loop. Yet there are many threads saying just go with distilled water with your copper blocks and you'll be fine, and none mention what to do about your fittings, which are unlikely to be copper.

So if you use normal copper blocks, how do you avoid a mixed metal loop and having to use anti-corrosives with distilled water? Or perhaps the fittings are safe - if so, would appreciate someone explaining why my loop is safe.

p.s. and what about silver coils? It's a different metal and any mixed metal should contribute a bit to corrosion, yet the assumption seems to be that it's safe. Any ideas why putting yet another different metal type in your watercooling loop is safe? Or should pure distilled water (without anti-corrosives/anti-bio) be avoided?

This time I'm using distilled water and dyes rather than all-in-one pre-mix. I'd like to avoid corrosion resulting from mixed metals coming into contact with water. There are many threads on the topic but they almost all simply say that distilled water is great and you'll be fine if you simply avoid mixed metals and it's a waste of cash to get anti-corrosives. Seems reasonable, but how do you avoid mixed metals?.

My blocks are all copper as is my radiator, but the fittings I'm using aren't copper. Seems to me that the fittings are exposed to the water just as much as the water blocks, meaning my loop is mixed metal. In fact, given that few fittings are copper as it's a fairly soft metal, this means almost everyone with copper blocks is going to have a mixed metal loop. Yet there are many threads saying just go with distilled water with your copper blocks and you'll be fine, and none mention what to do about your fittings, which are unlikely to be copper.

So if you use normal copper blocks, how do you avoid a mixed metal loop and having to use anti-corrosives with distilled water? Or perhaps the fittings are safe - if so, would appreciate someone explaining why my loop is safe.

p.s. and what about silver coils? It's a different metal and any mixed metal should contribute a bit to corrosion, yet the assumption seems to be that it's safe. Any ideas why putting yet another different metal type in your watercooling loop is safe? Or should pure distilled water (without anti-corrosives/anti-bio) be avoided?

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)