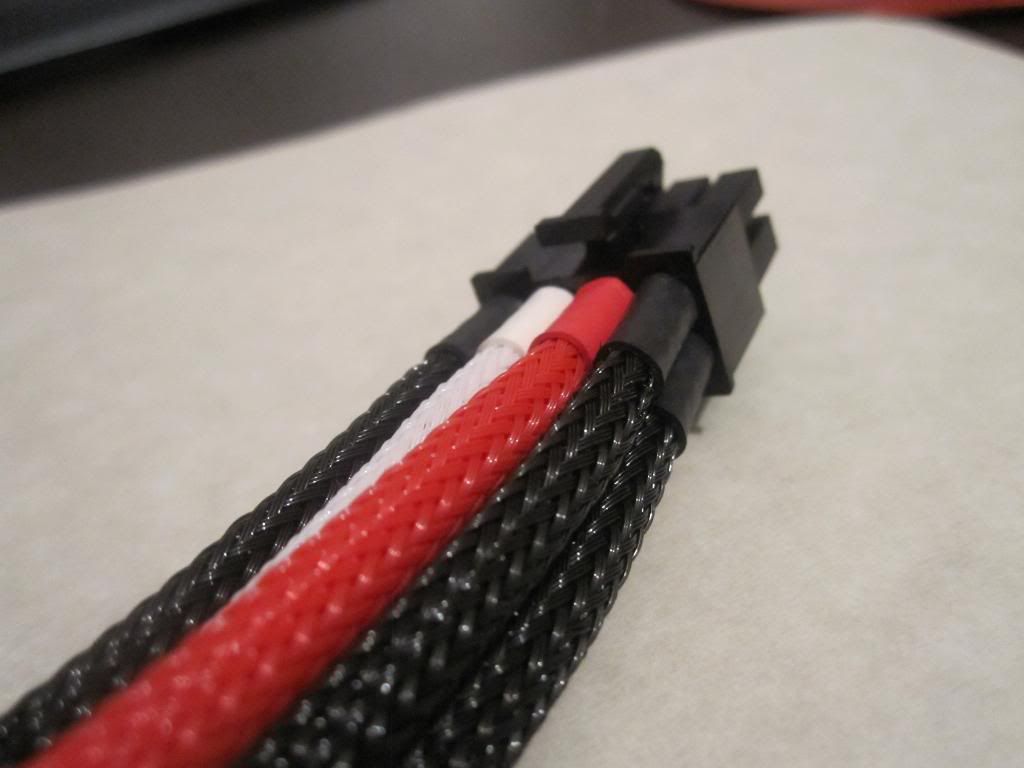

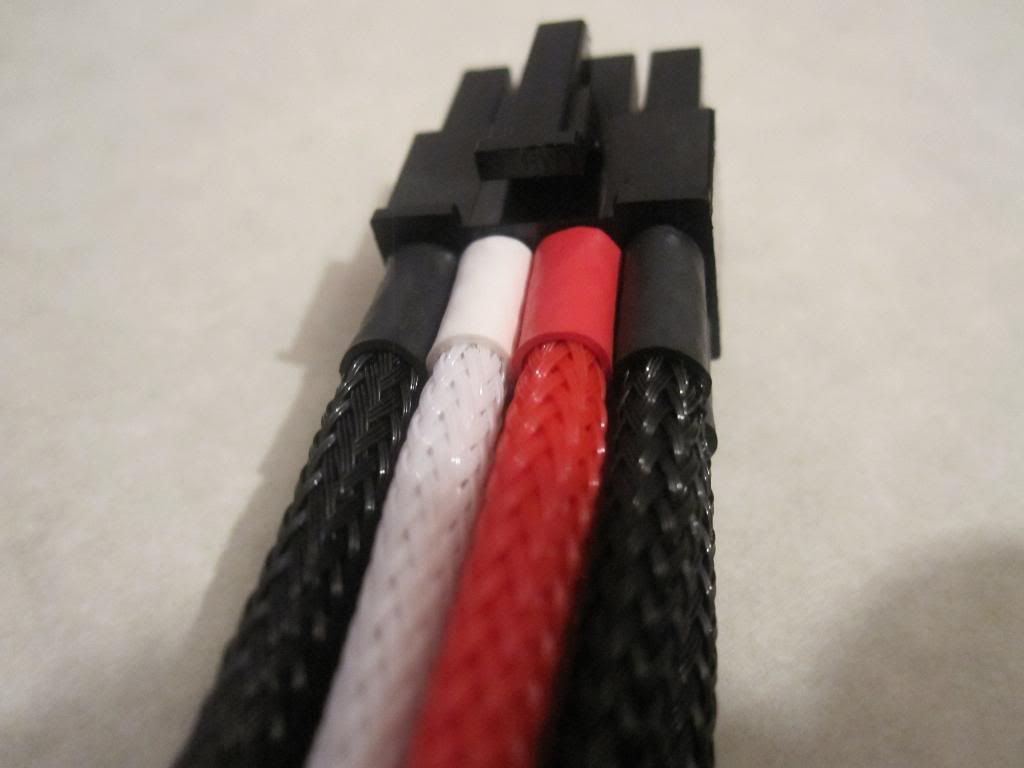

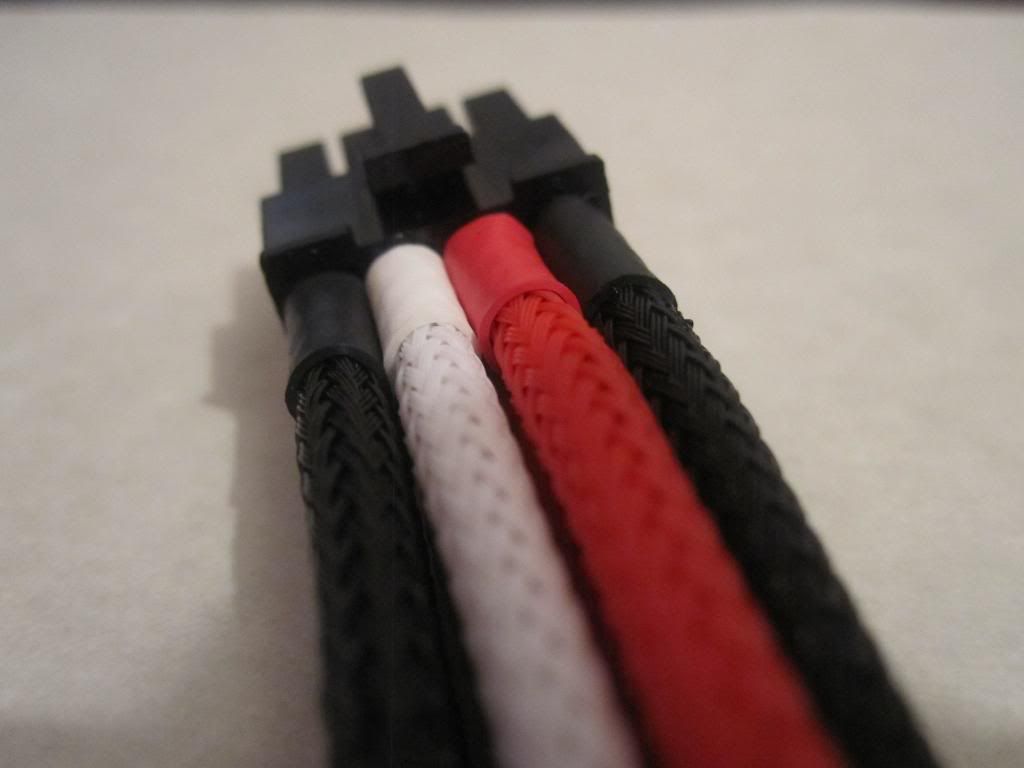

SINGLE SLEEVED WIRE GUIDE BY KAMASTER

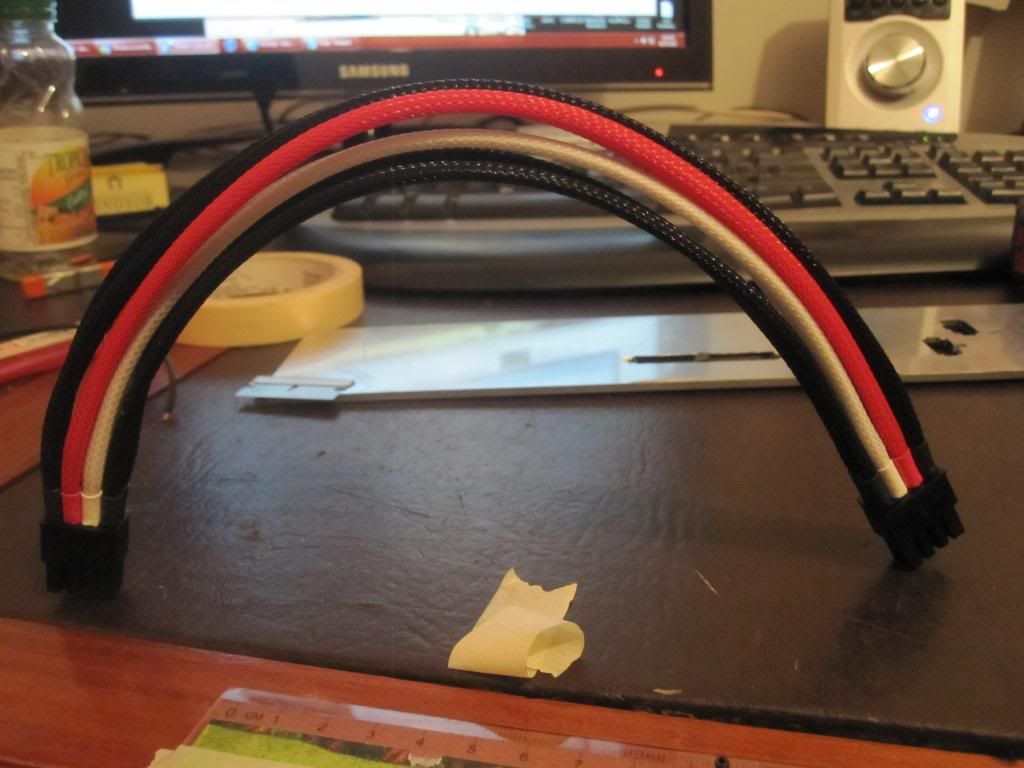

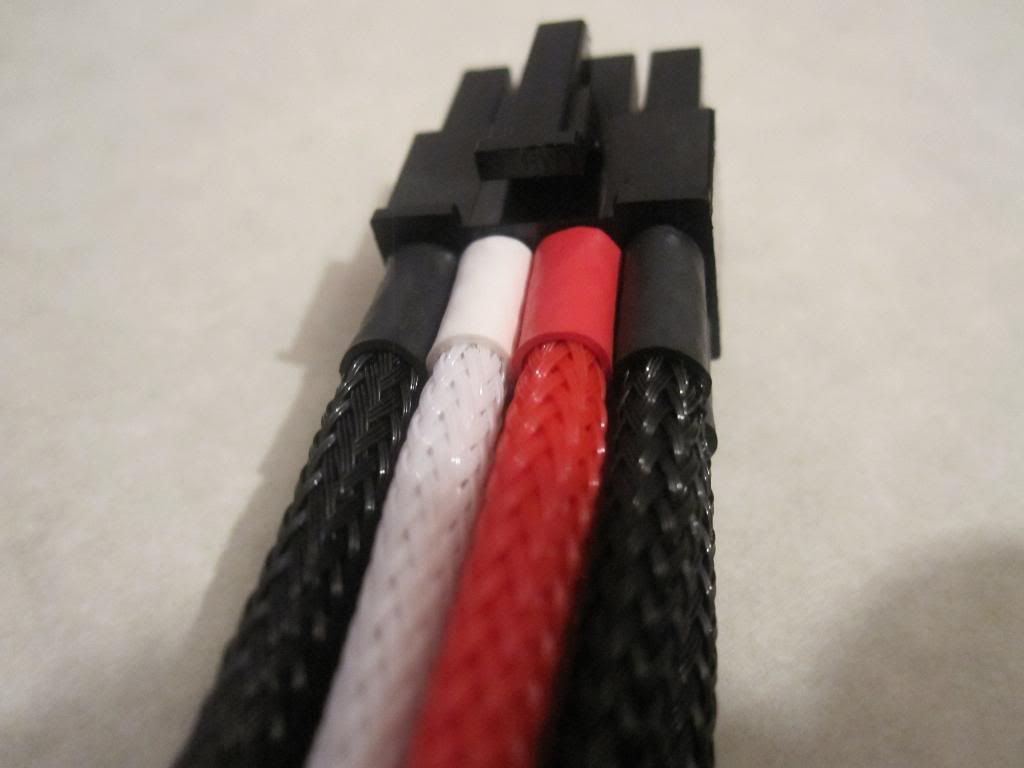

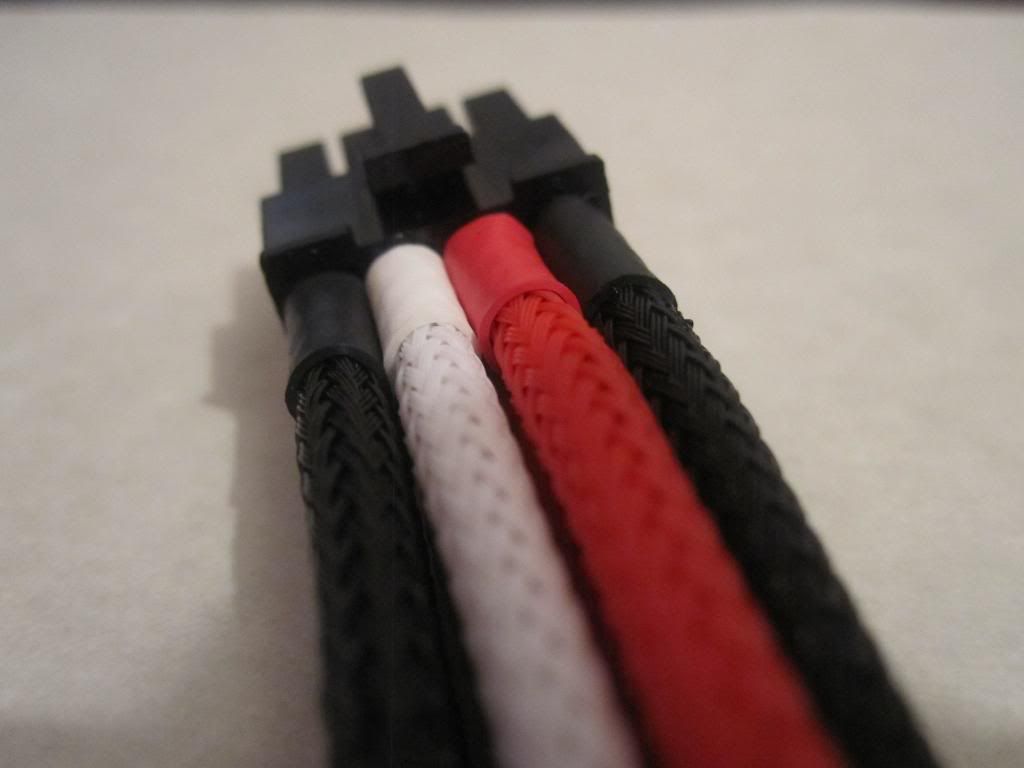

MDPC-X SINGLE SLEEVED CABLED AT THEIR FINEST

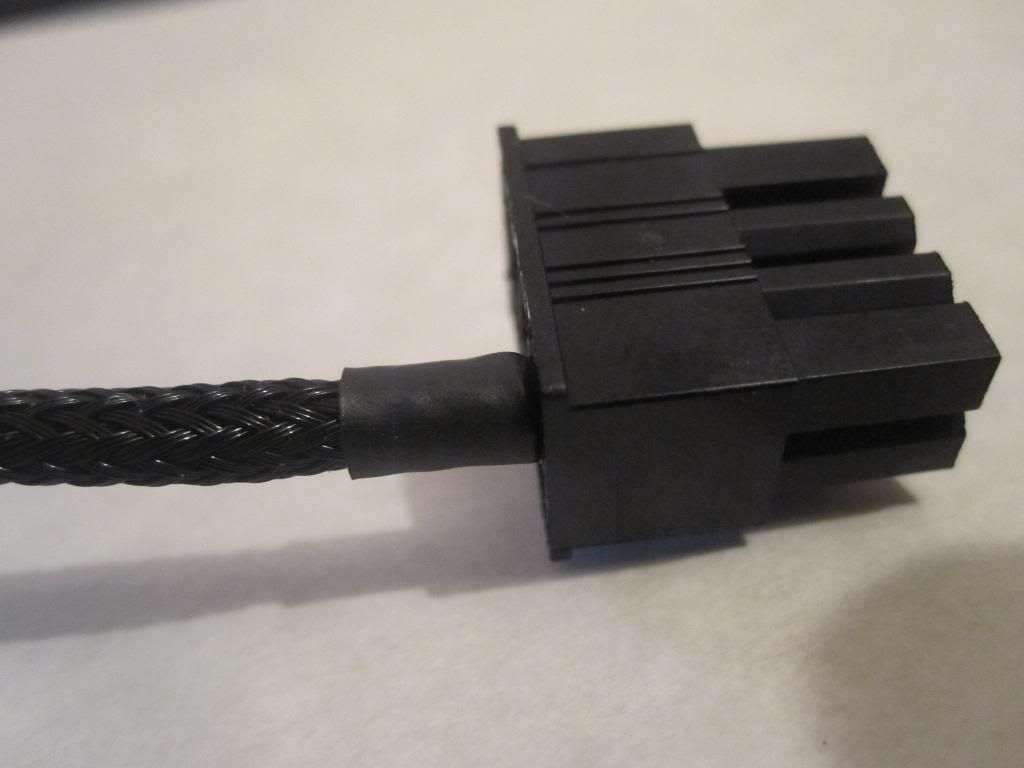

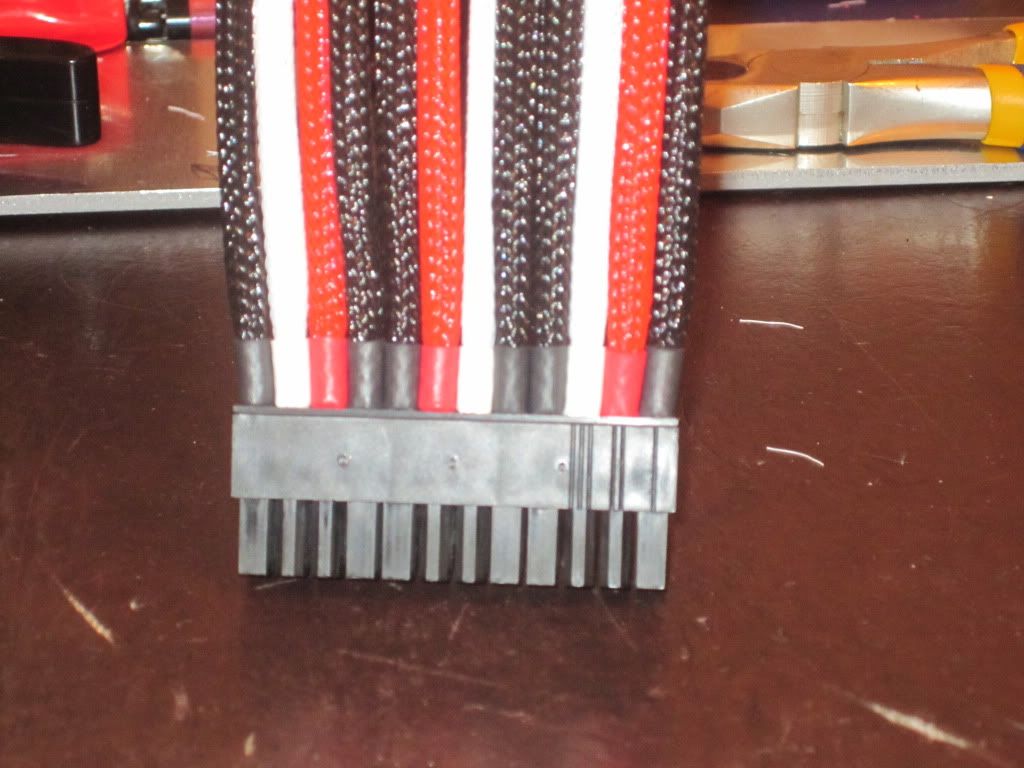

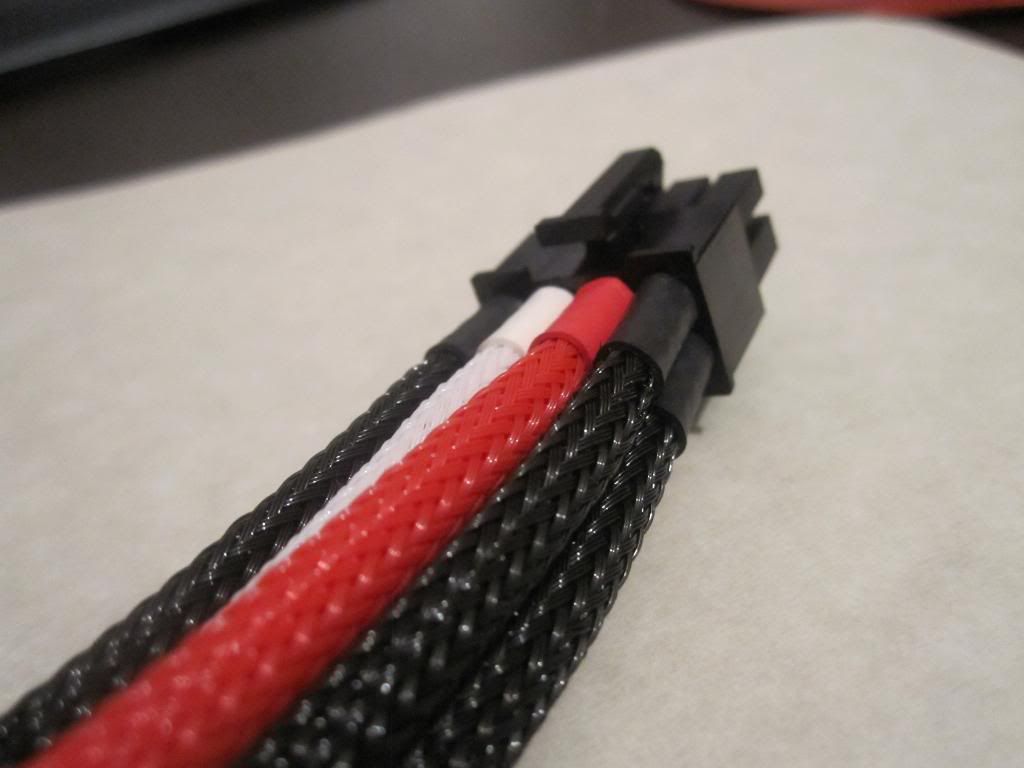

I received a request from a member of another forum for a guide on how to single (individually) sleeve your power supply or custom made cables with MDPC-X sleeving and heatshrink. This is my technique and it can be done many other ways I find this works well and gives good results (all the heatshrink lines up perfectly).

I find this works well and gives good results (all the heatshrink lines up perfectly).

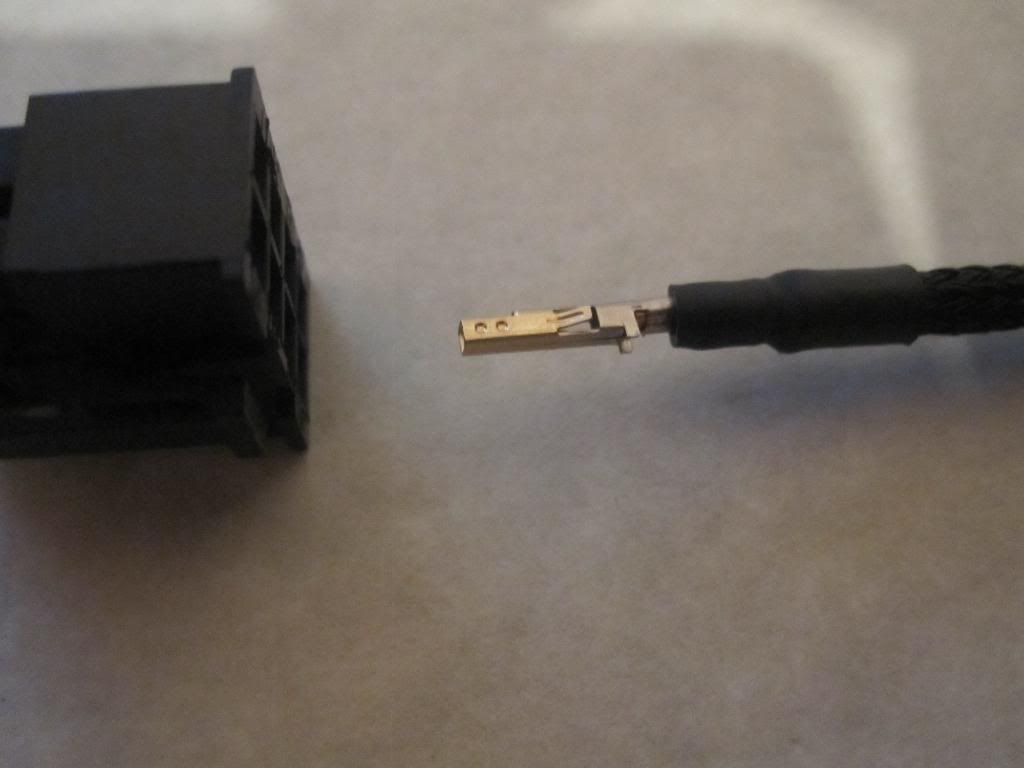

I have used these techniques on my FERMI 2 build, CHECK IT OUT!!!!!

First you are going to need some tools and tools, heres the list:

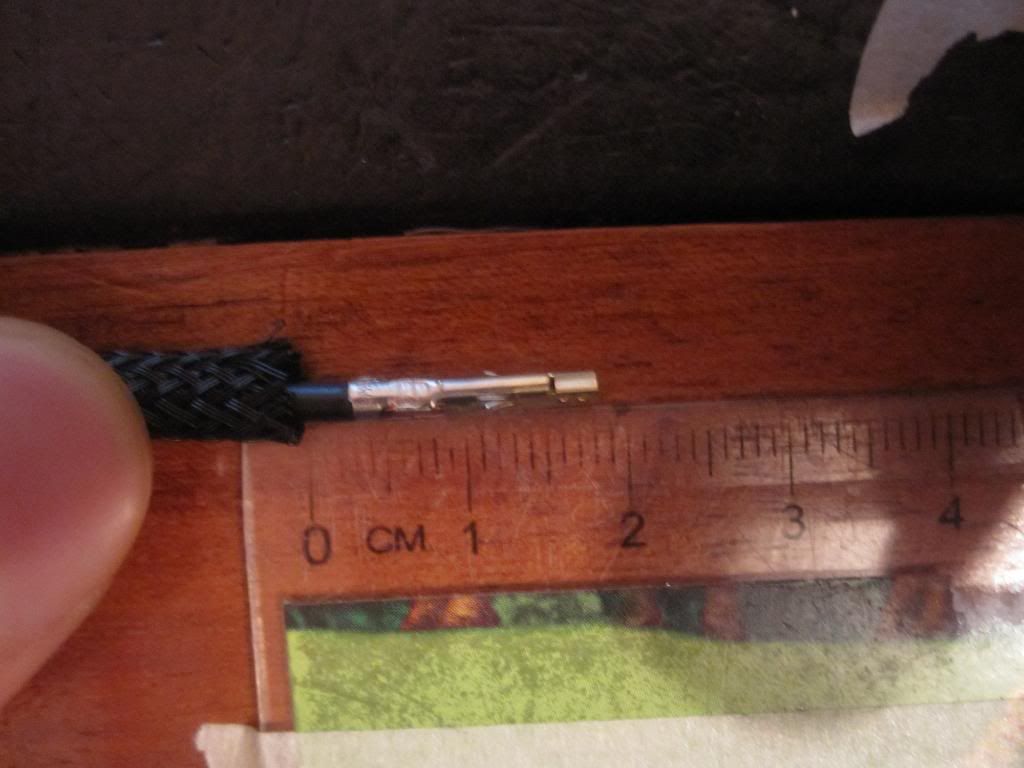

1. MDPC-X small sleeving

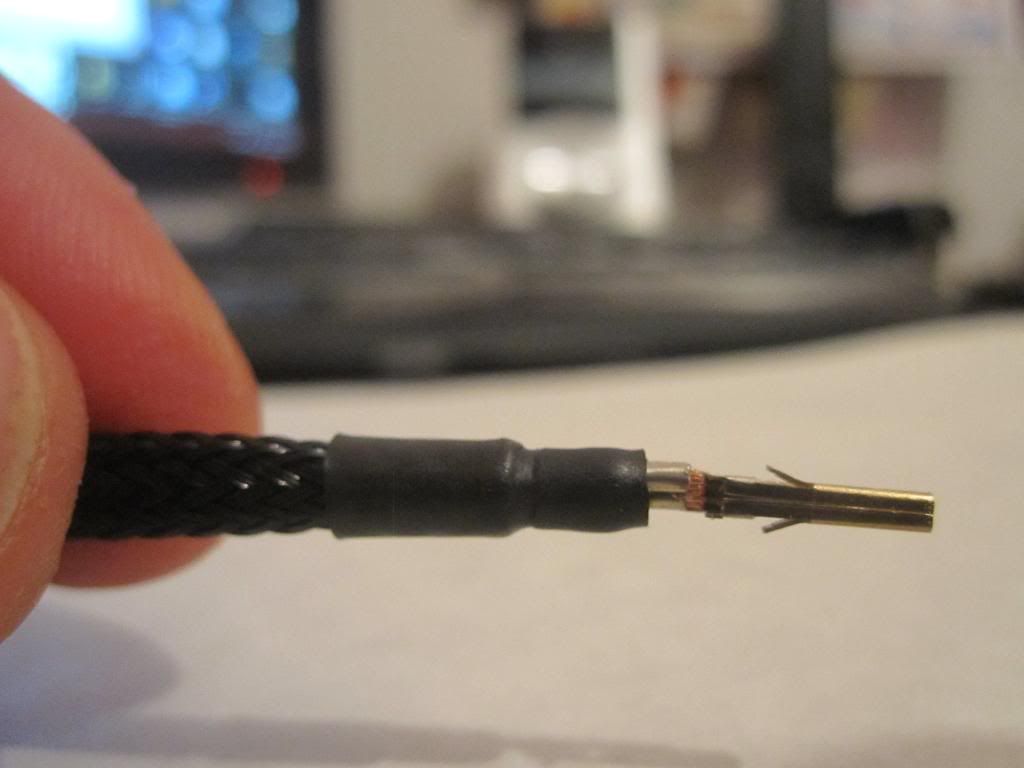

2. MDPC-X Pre-cut heatshrink (15mm long)

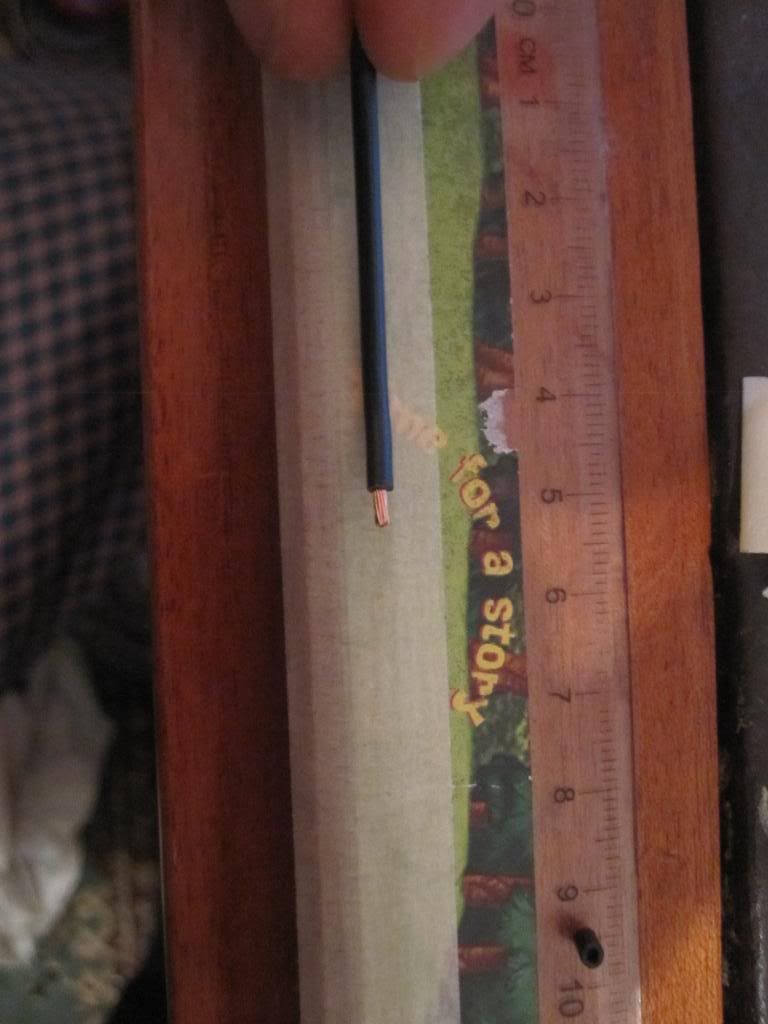

3. 18 Gauge Wire ( I used automotive stuff - seems to have a thicker pvc wall than the regular stuff)

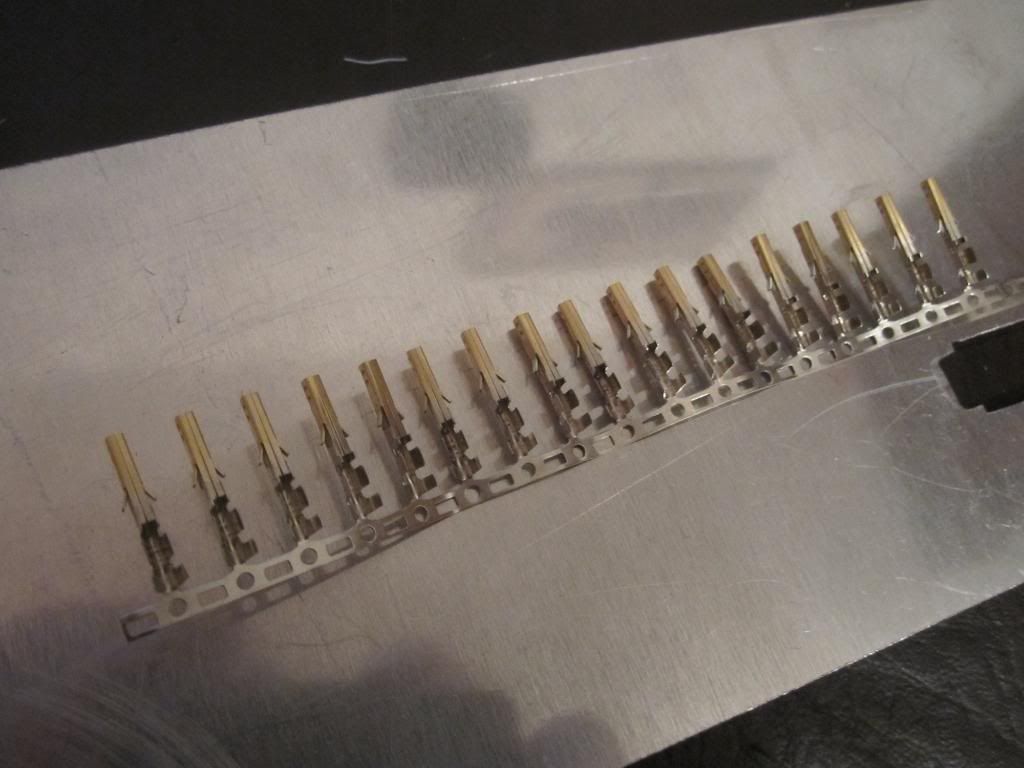

4. ATX male and/or female connector pins

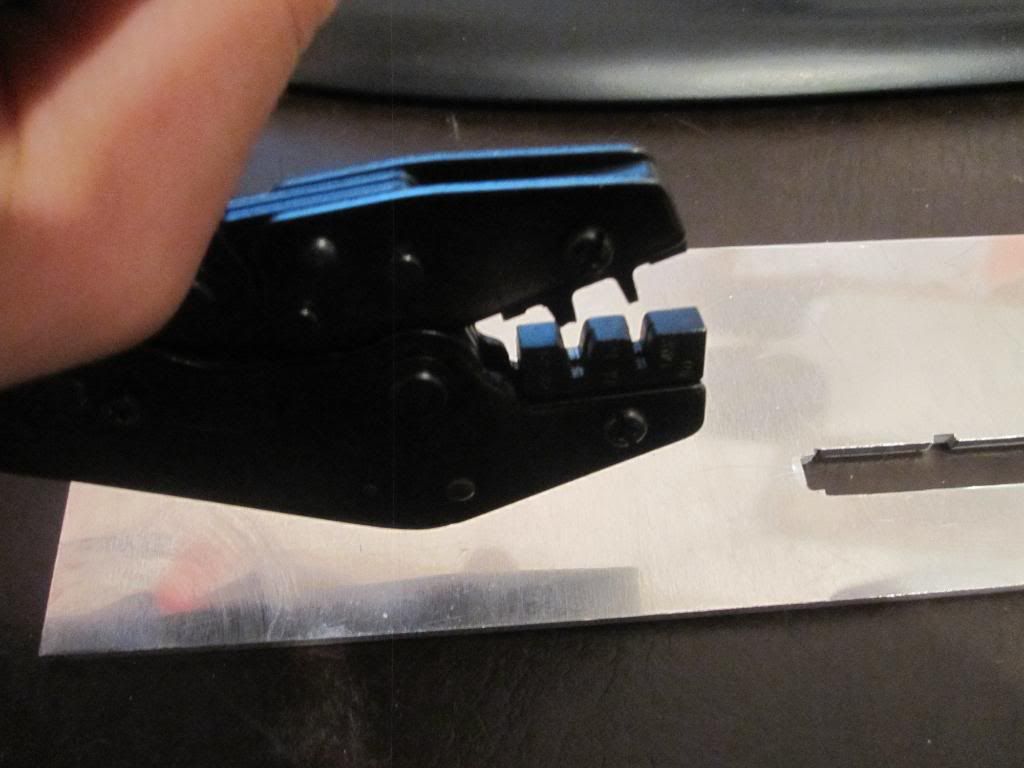

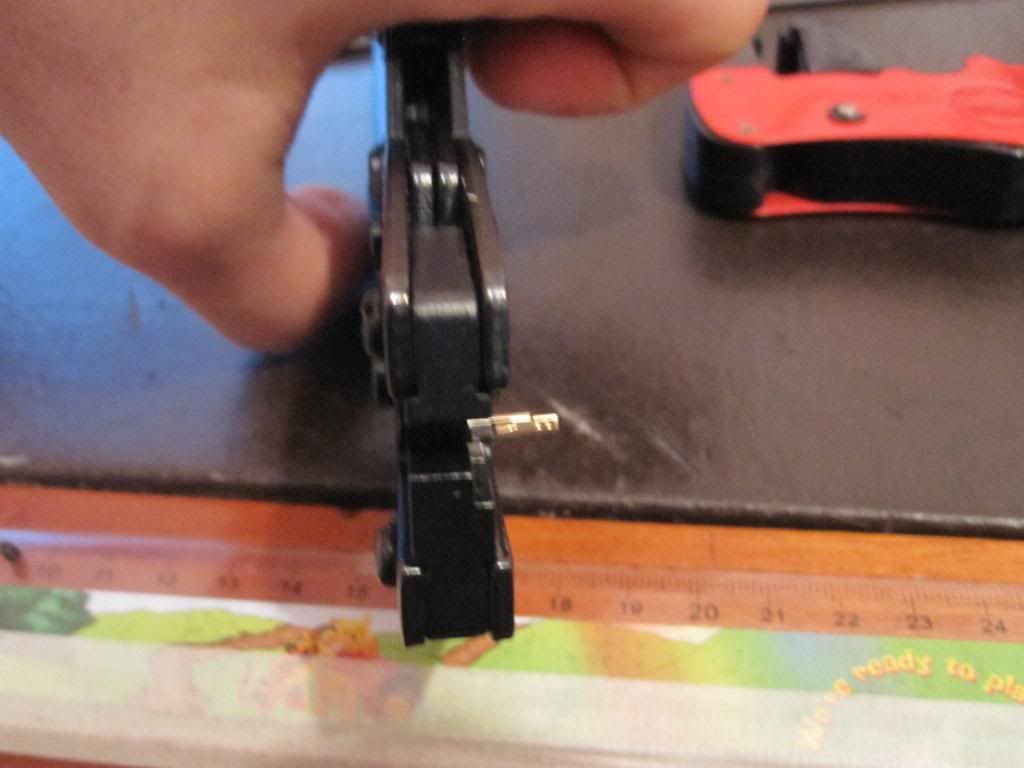

5. ATX pin Crimping tool

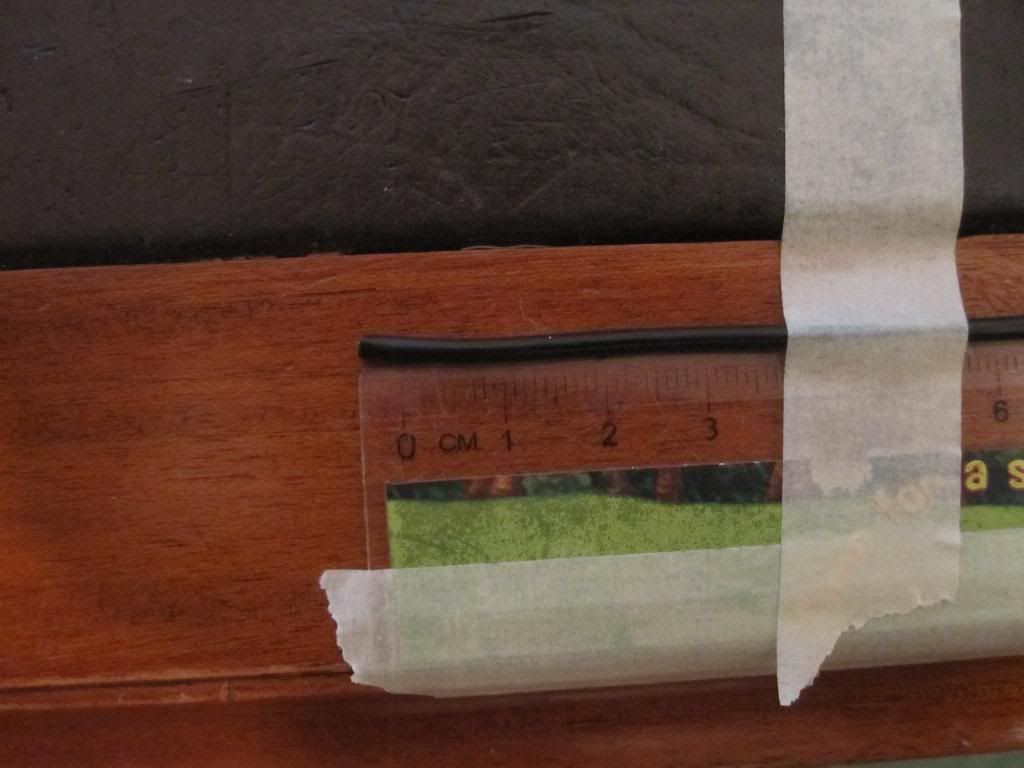

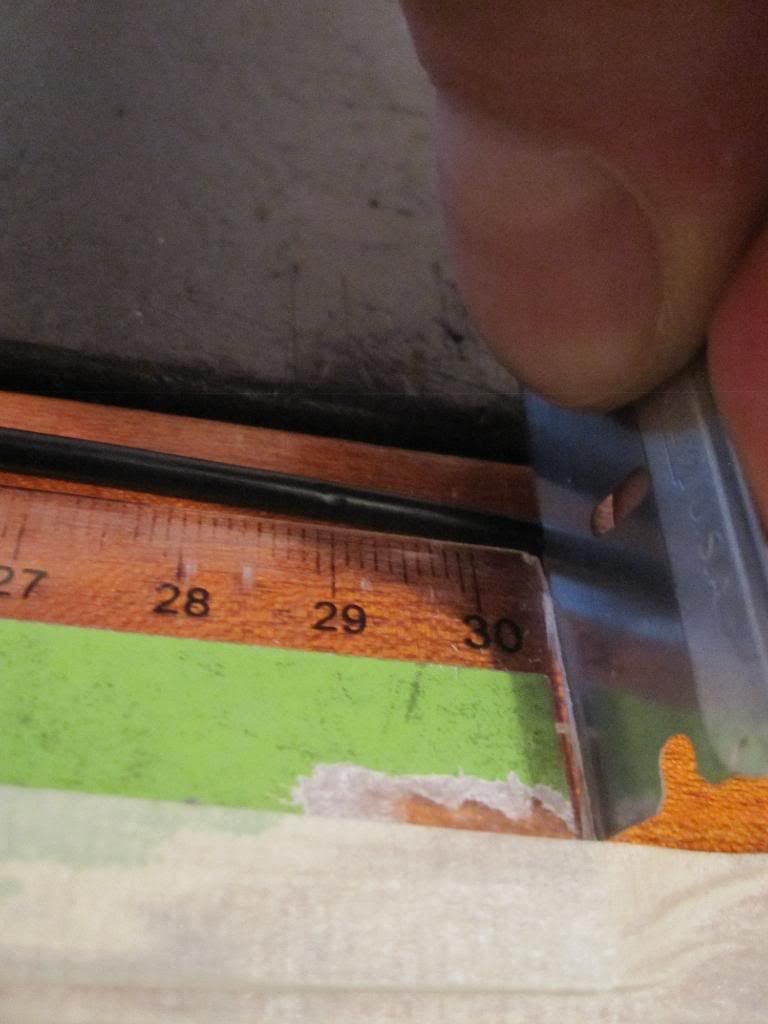

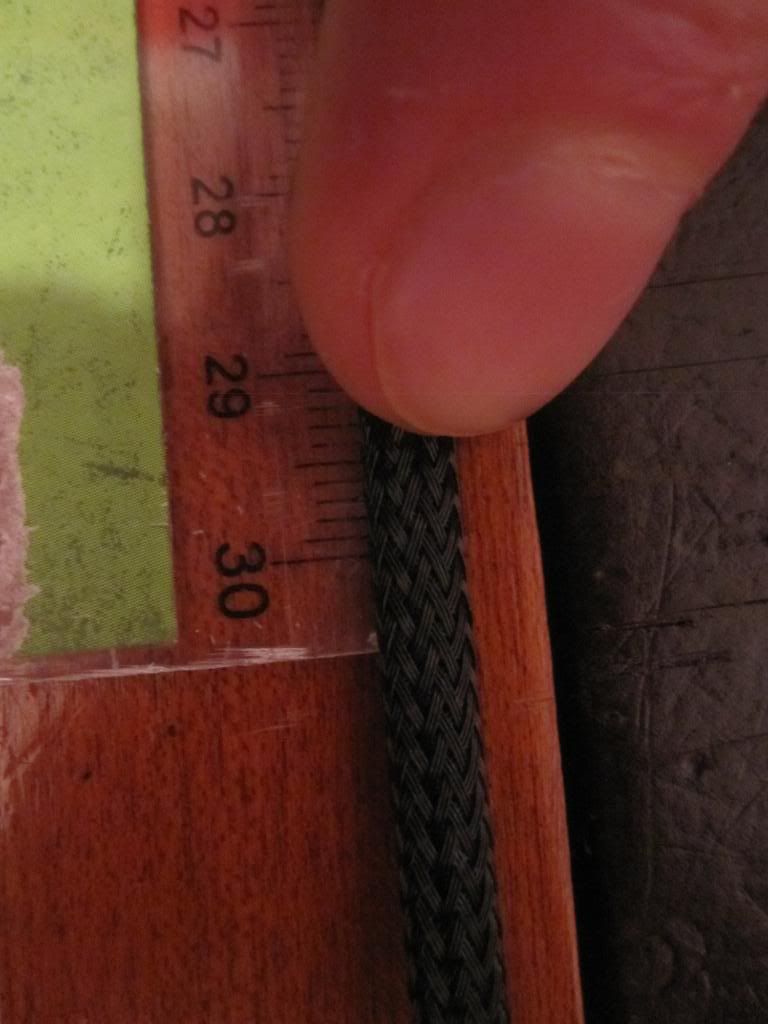

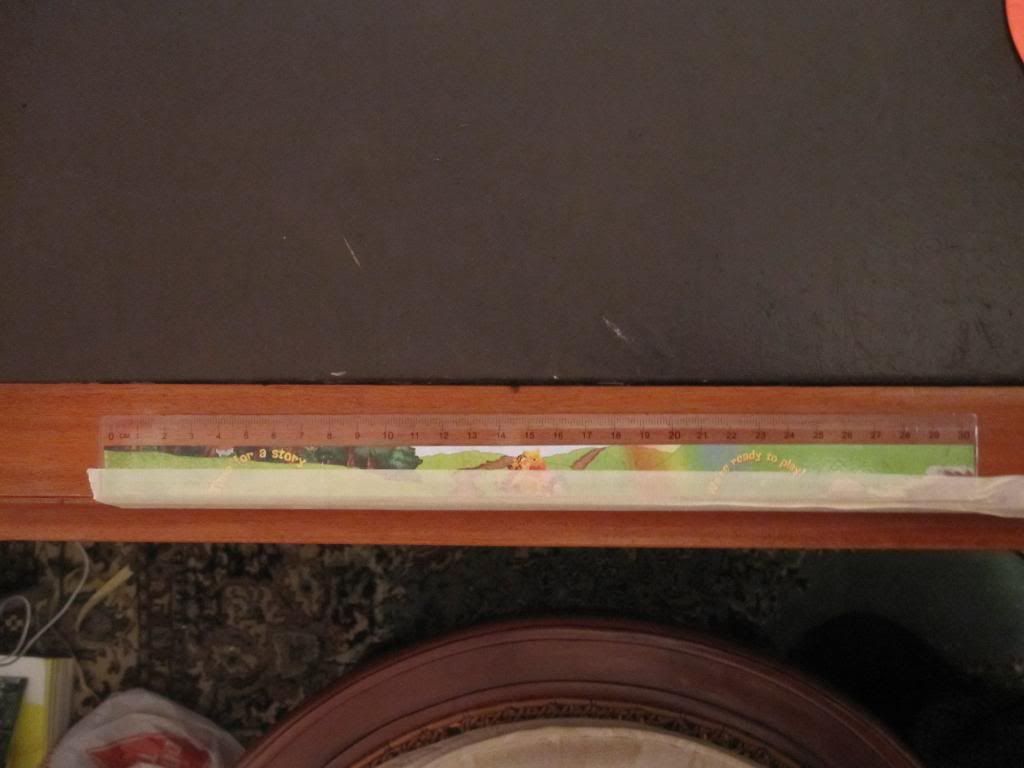

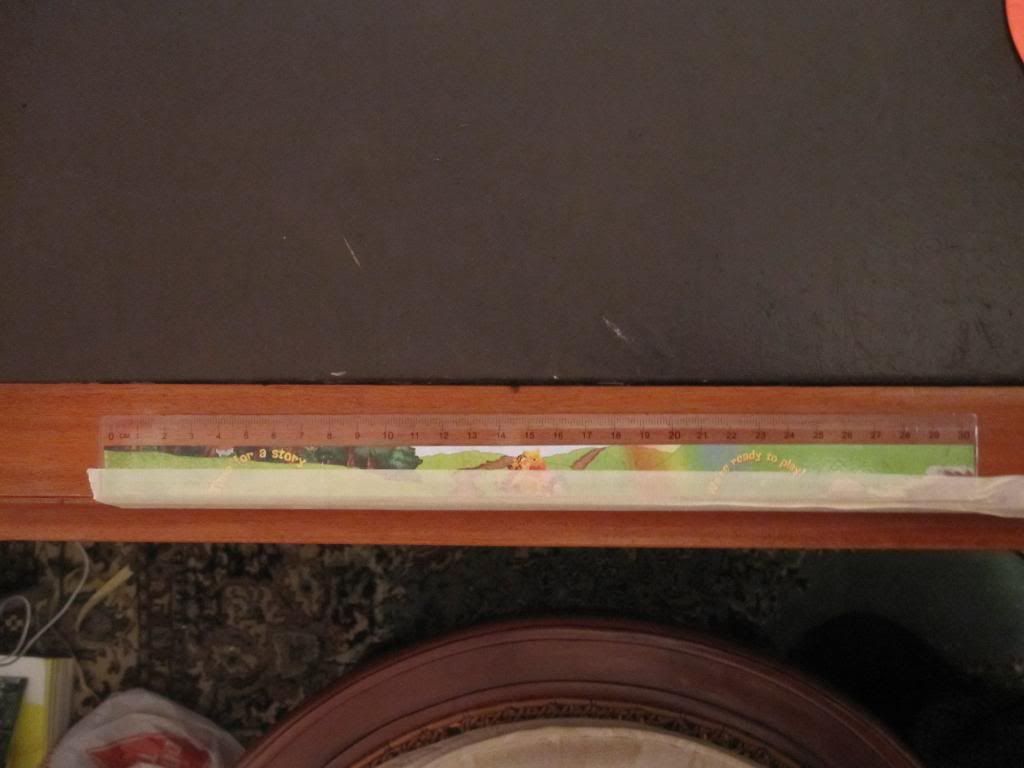

6. Ruler

7. Masking tape

8. Pliers (that can cut wire)

9. Wire stripper (preferably like the one i have but standard ones are fine)

10. Measuring tape

11. Good pair of scissors (dont use a cheap pair if you want good results $15-40)

12. Lighter

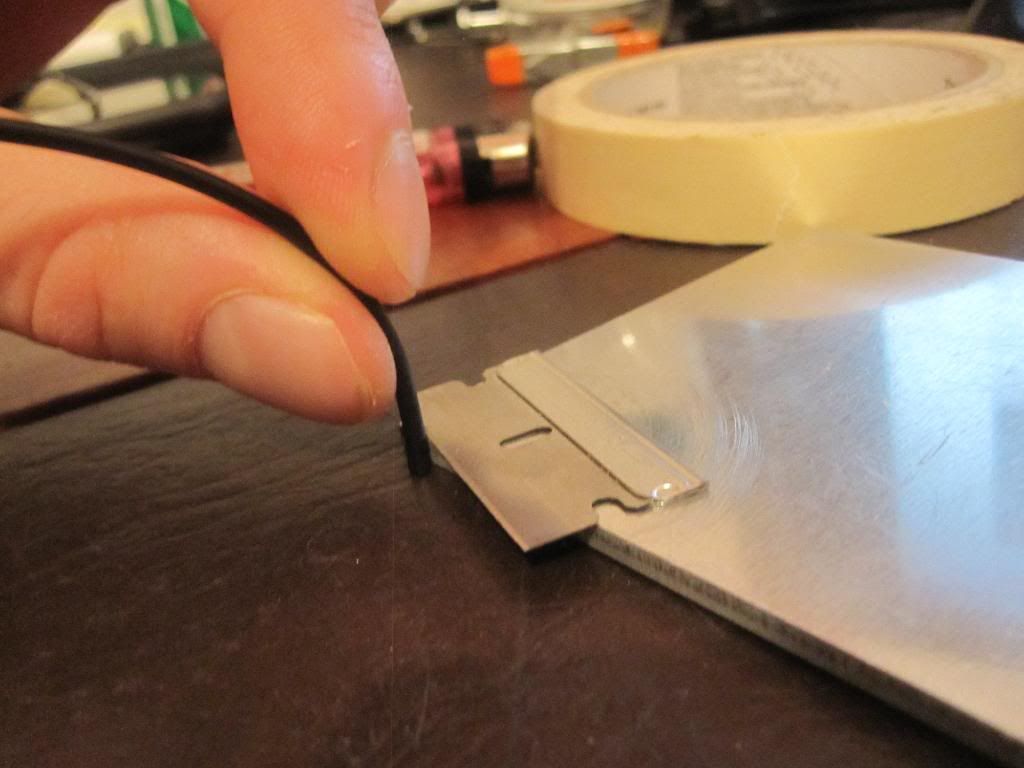

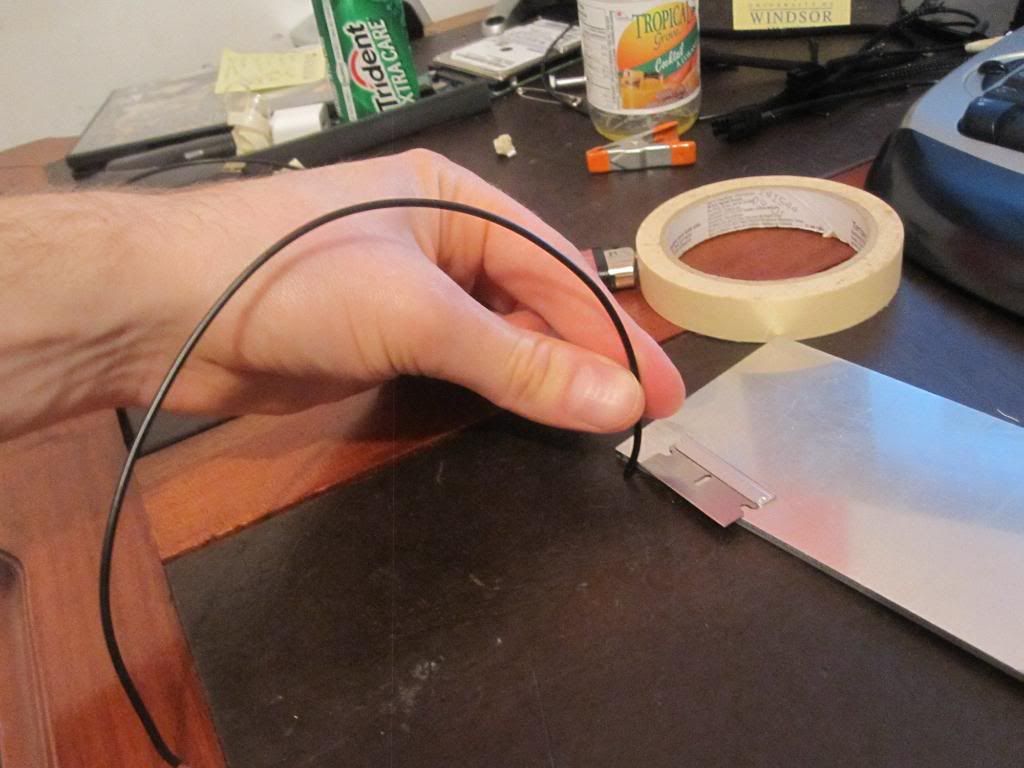

13. Razor blade (see pic)

14. 1/8" (3mm) Aluminum or any other material 1/8" thick) atleast 3" x 5" in dimensions

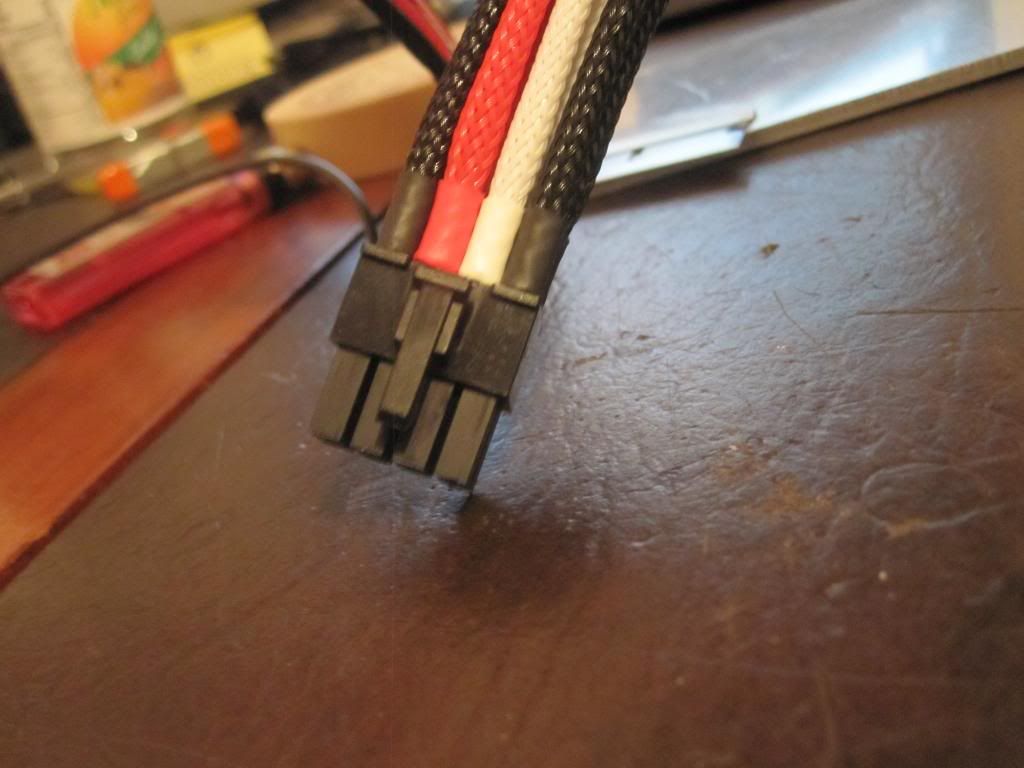

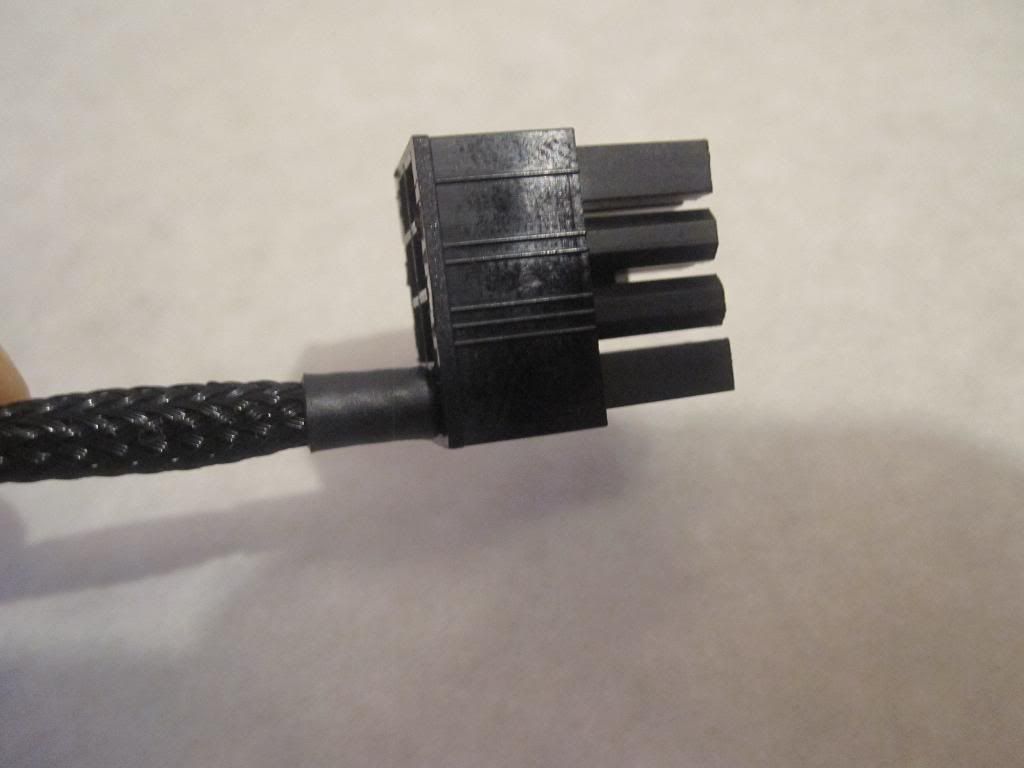

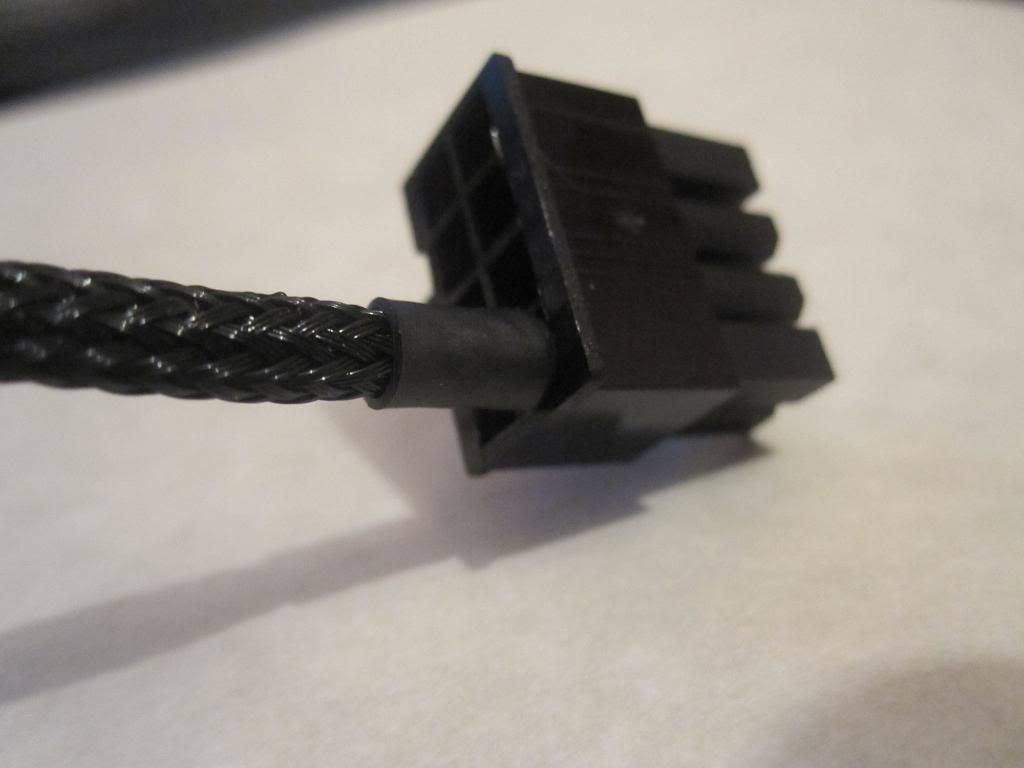

15. ATX Connectors (8pin EPS, 4pin P4, 6 pin PCI-E, 8 pin PCI-E (or 6+2pin), 24 or 20 Pin ATX Mobo)

16. Flat working area

17. Heat Gun (with low and high setting)

18. ATX Pin remover

19. A LOT OF PATIENCE!!!!!!! and time (when you master it, it becomes very easy)

Here are some pics of the tools I used...

High and low settings (high heat, low heat)

MDPC-X SINGLE SLEEVED CABLED AT THEIR FINEST

I received a request from a member of another forum for a guide on how to single (individually) sleeve your power supply or custom made cables with MDPC-X sleeving and heatshrink. This is my technique and it can be done many other ways

I have used these techniques on my FERMI 2 build, CHECK IT OUT!!!!!

First you are going to need some tools and tools, heres the list:

1. MDPC-X small sleeving

2. MDPC-X Pre-cut heatshrink (15mm long)

3. 18 Gauge Wire ( I used automotive stuff - seems to have a thicker pvc wall than the regular stuff)

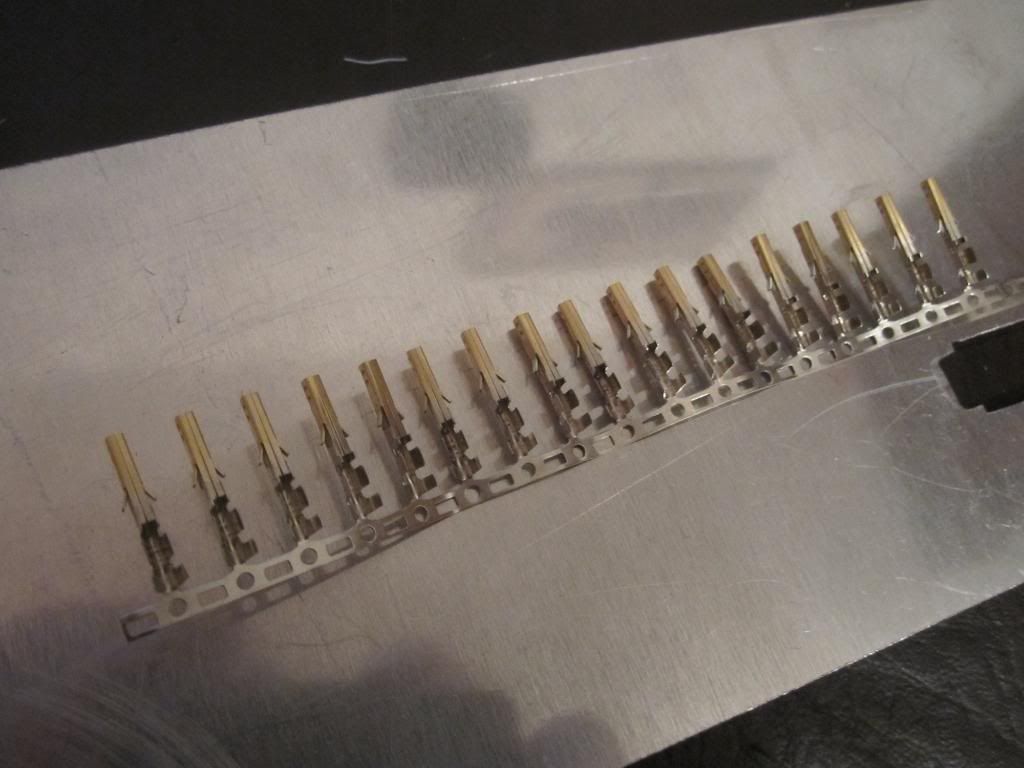

4. ATX male and/or female connector pins

5. ATX pin Crimping tool

6. Ruler

7. Masking tape

8. Pliers (that can cut wire)

9. Wire stripper (preferably like the one i have but standard ones are fine)

10. Measuring tape

11. Good pair of scissors (dont use a cheap pair if you want good results $15-40)

12. Lighter

13. Razor blade (see pic)

14. 1/8" (3mm) Aluminum or any other material 1/8" thick) atleast 3" x 5" in dimensions

15. ATX Connectors (8pin EPS, 4pin P4, 6 pin PCI-E, 8 pin PCI-E (or 6+2pin), 24 or 20 Pin ATX Mobo)

16. Flat working area

17. Heat Gun (with low and high setting)

18. ATX Pin remover

19. A LOT OF PATIENCE!!!!!!! and time (when you master it, it becomes very easy)

Here are some pics of the tools I used...

High and low settings (high heat, low heat)

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)