TeeJayHoward

Limpness Supreme

- Joined

- Feb 8, 2005

- Messages

- 12,268

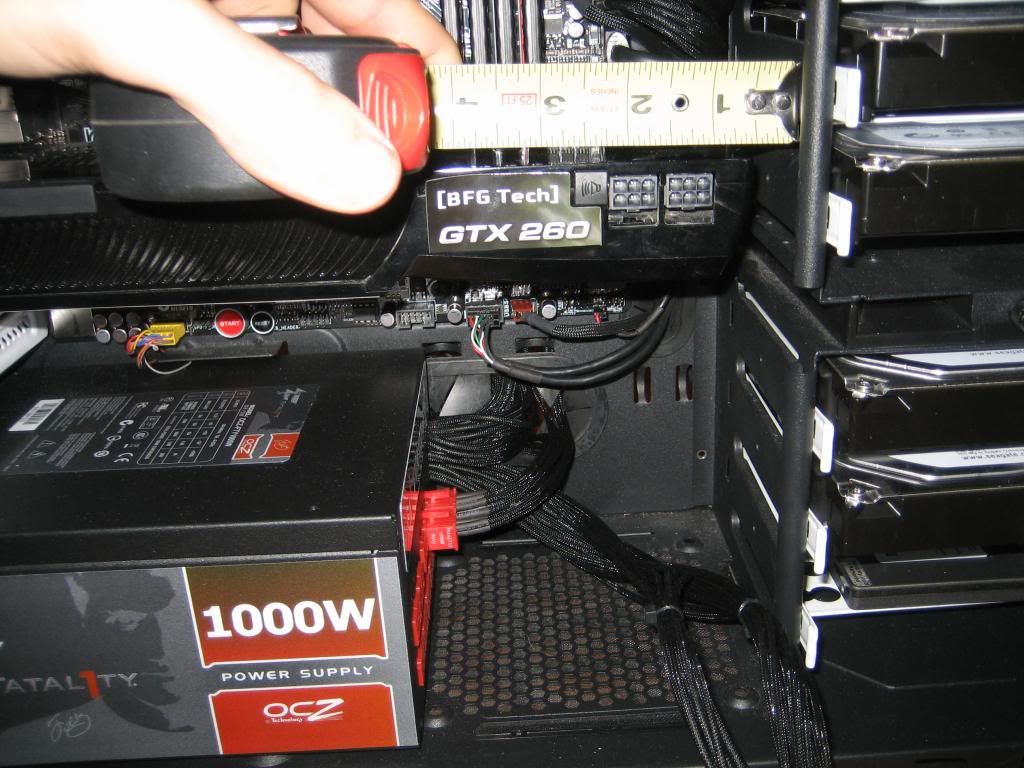

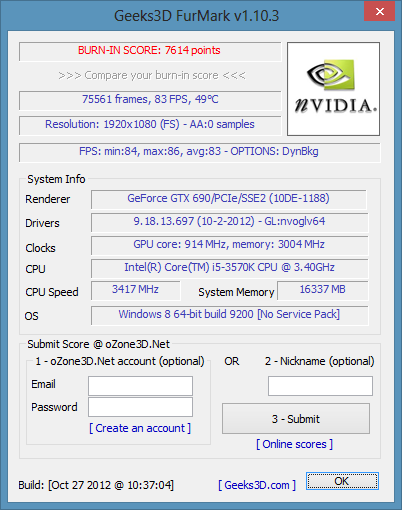

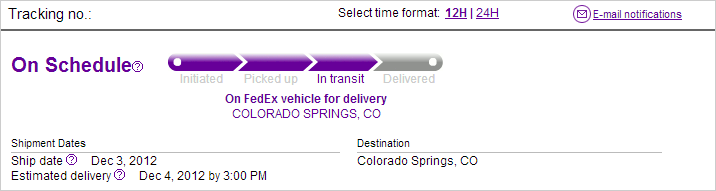

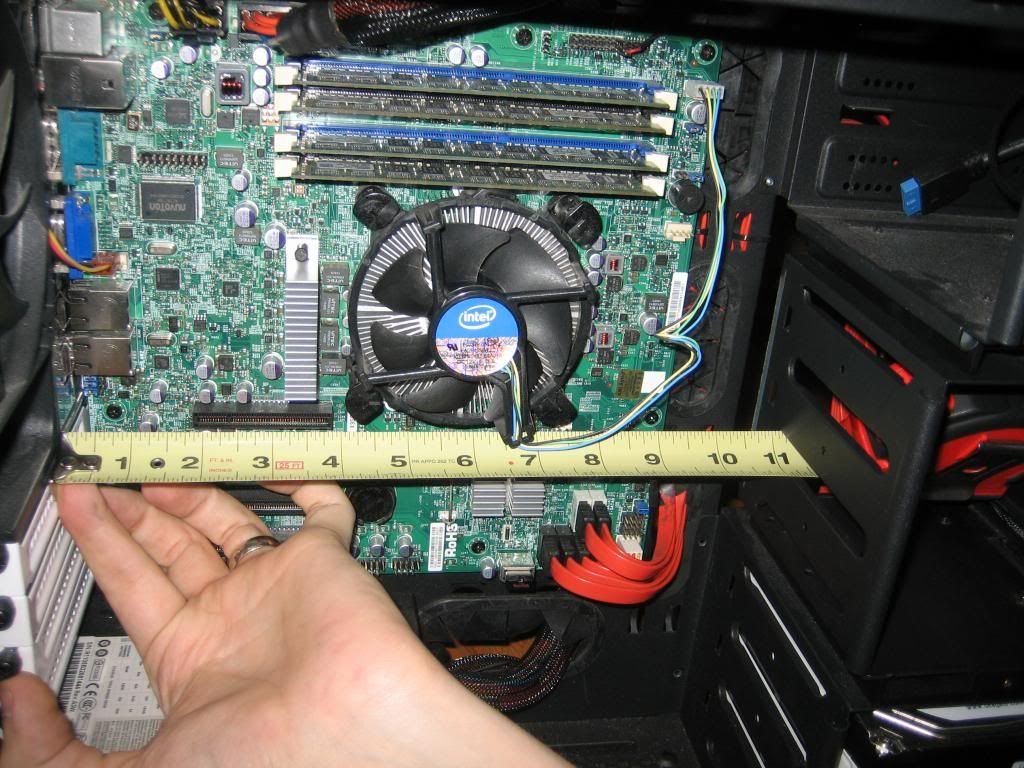

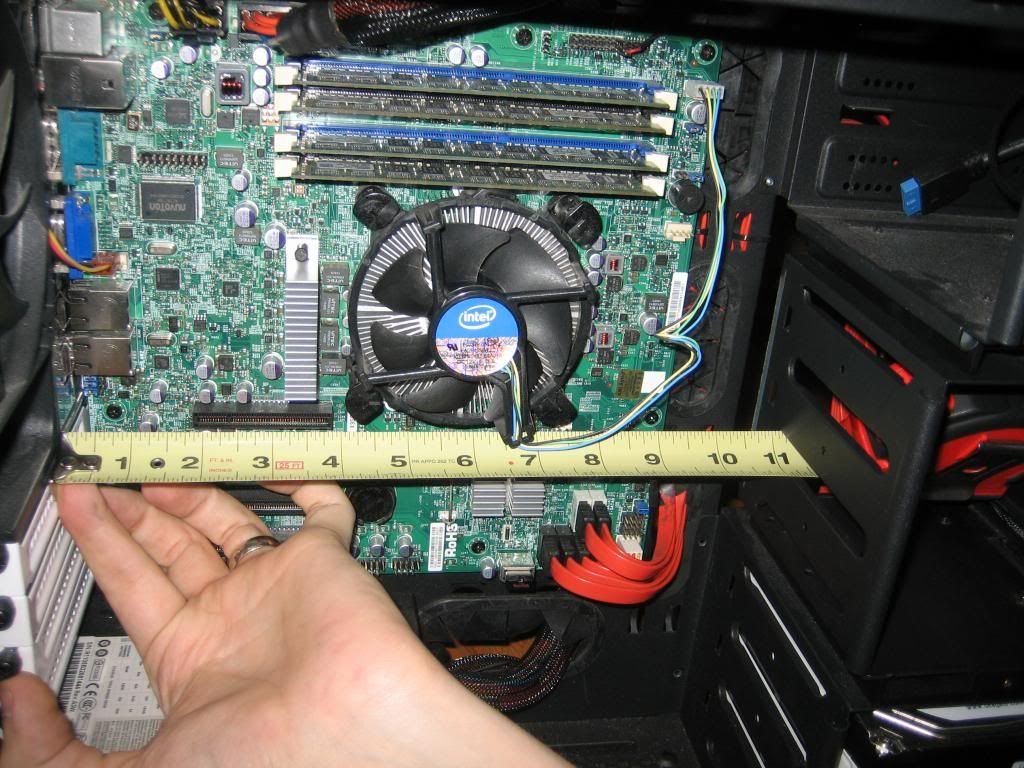

Sometimes, all you need is that extra quarter inch. I've got a Fractal Design Define Mini, and I'm thinking about a GTX 690. That's an 11 inch card, and according to Fractal Design, this case only supports video cards up to 260mm (10.23") in length with the HDD-bay in place. Well, bringing out the measuring tape shows that there's actually room for a 10.8" or so card. It seems silly to ditch a case I love because it's a bit under a quarter inch too narrow in one direction. So I decided to try and modify it to fit. I started by investigating the issue. (Ignore the server motherboard - I measured on my NAS, but the new drive tray will be going into my gaming rig.)

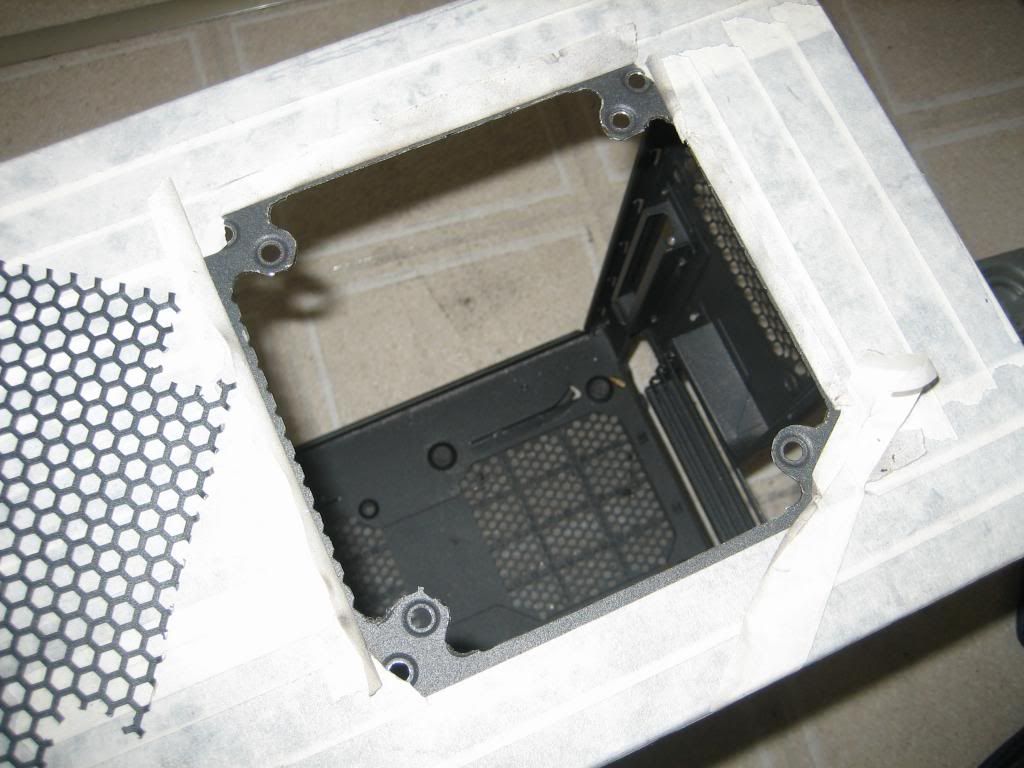

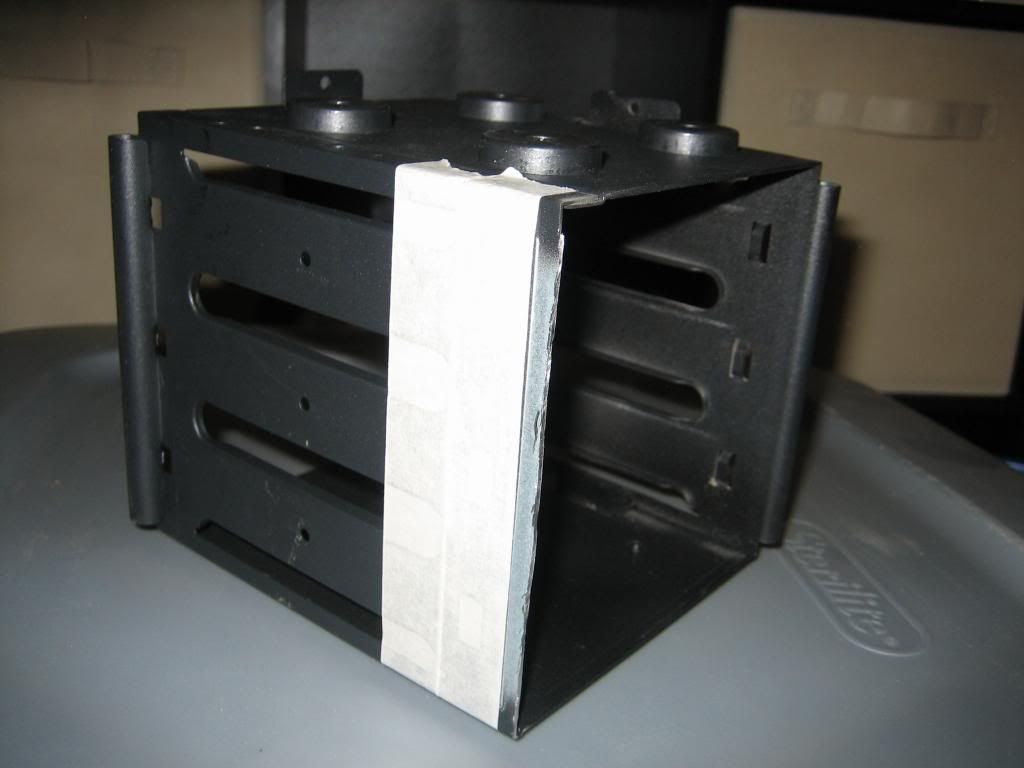

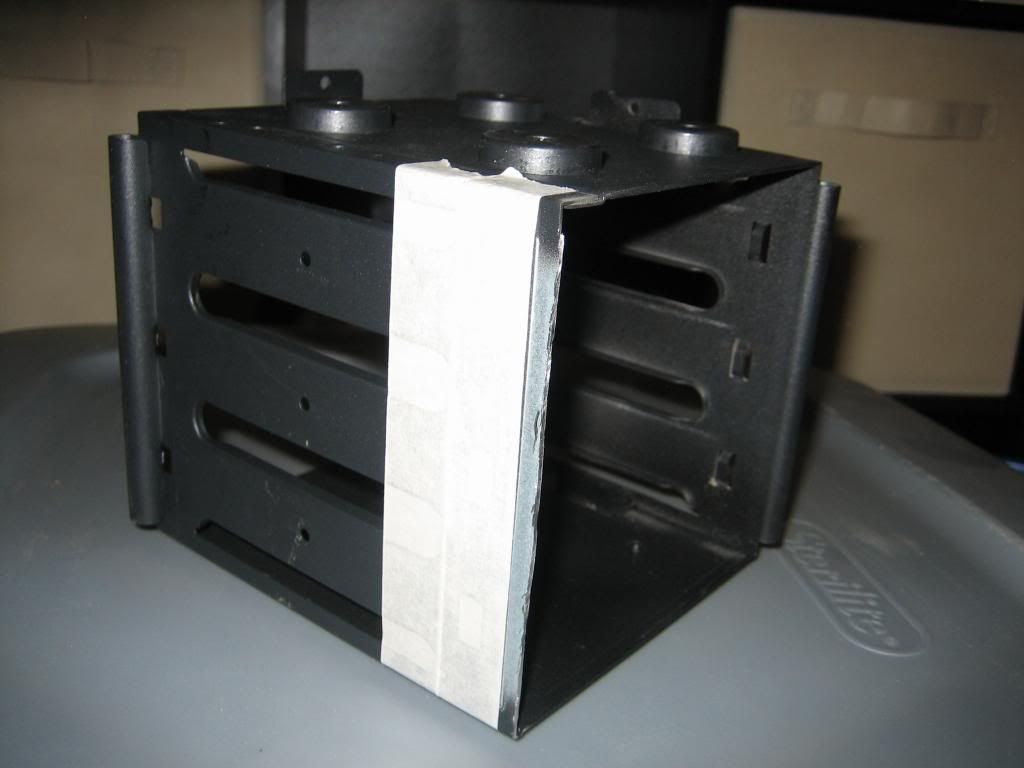

Okay, it looks like there's two ways to go about it. If I drill new holes, I can move both drive cages about a tenth of an inch closer to the fans. That MIGHT get me the space I need. The alternative is to remove the pleasantly rounded lip on the drive cage. That would gain me a bit more room. Well, I loves me some Dremel, and trying to cut a hole for a screw at an angle would be a pain, so… Drive cage it is! I start by removing the cage and taping off everything:

Tape makes a nice guide line along the inside for me to cut.

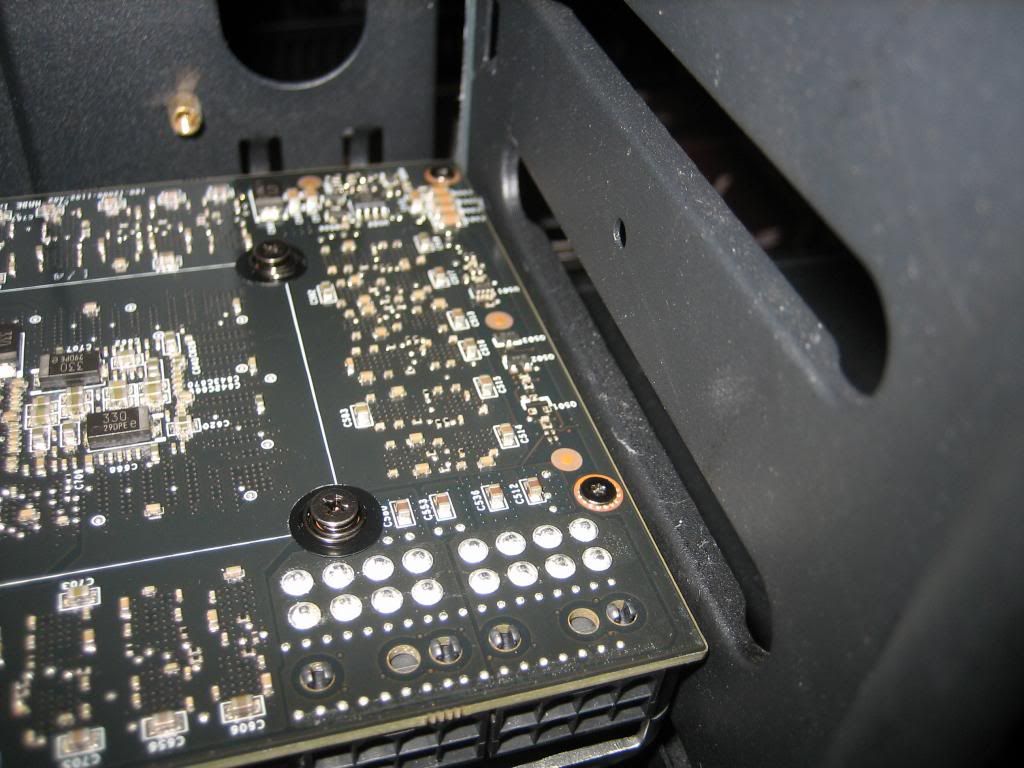

A few minutes with the dremel later, I end up with this:

That's one jagged line! Stupid shaky hands. A few minutes with a file should clean that right up, though!

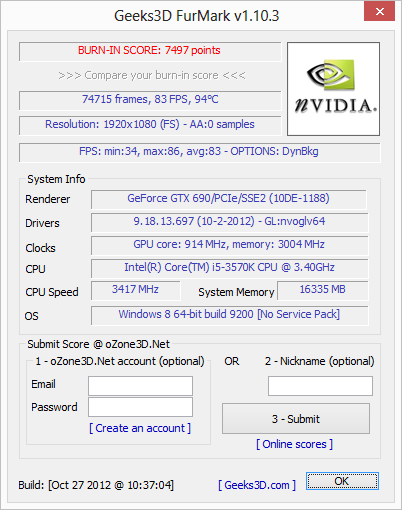

And now, I have a touch over 11" to play with!

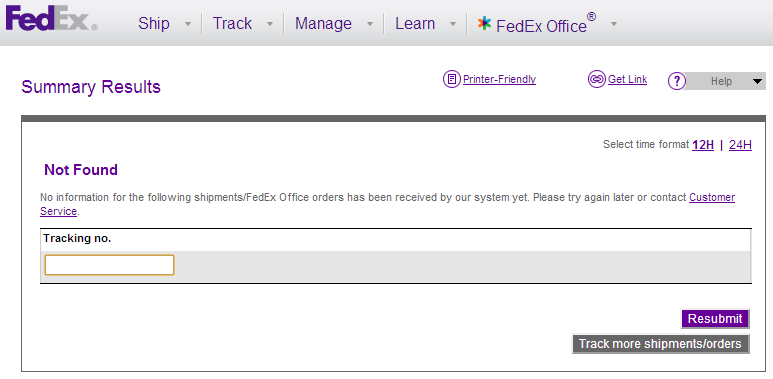

I'd love to show ya what the card looks like in the case, and rather or not it was successful, but unfortunately, I don't quite have all the components yet! I'll drop back by and update this once my parts come in. Going to do my best to fit a 3x120mm radiator up top and water cool it all!

Okay, it looks like there's two ways to go about it. If I drill new holes, I can move both drive cages about a tenth of an inch closer to the fans. That MIGHT get me the space I need. The alternative is to remove the pleasantly rounded lip on the drive cage. That would gain me a bit more room. Well, I loves me some Dremel, and trying to cut a hole for a screw at an angle would be a pain, so… Drive cage it is! I start by removing the cage and taping off everything:

Tape makes a nice guide line along the inside for me to cut.

A few minutes with the dremel later, I end up with this:

That's one jagged line! Stupid shaky hands. A few minutes with a file should clean that right up, though!

And now, I have a touch over 11" to play with!

I'd love to show ya what the card looks like in the case, and rather or not it was successful, but unfortunately, I don't quite have all the components yet! I'll drop back by and update this once my parts come in. Going to do my best to fit a 3x120mm radiator up top and water cool it all!

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)