Tengis

Supreme [H]ardness

- Joined

- Jun 11, 2003

- Messages

- 6,088

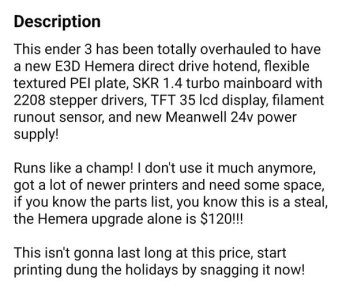

Well this was the description when I bought it:

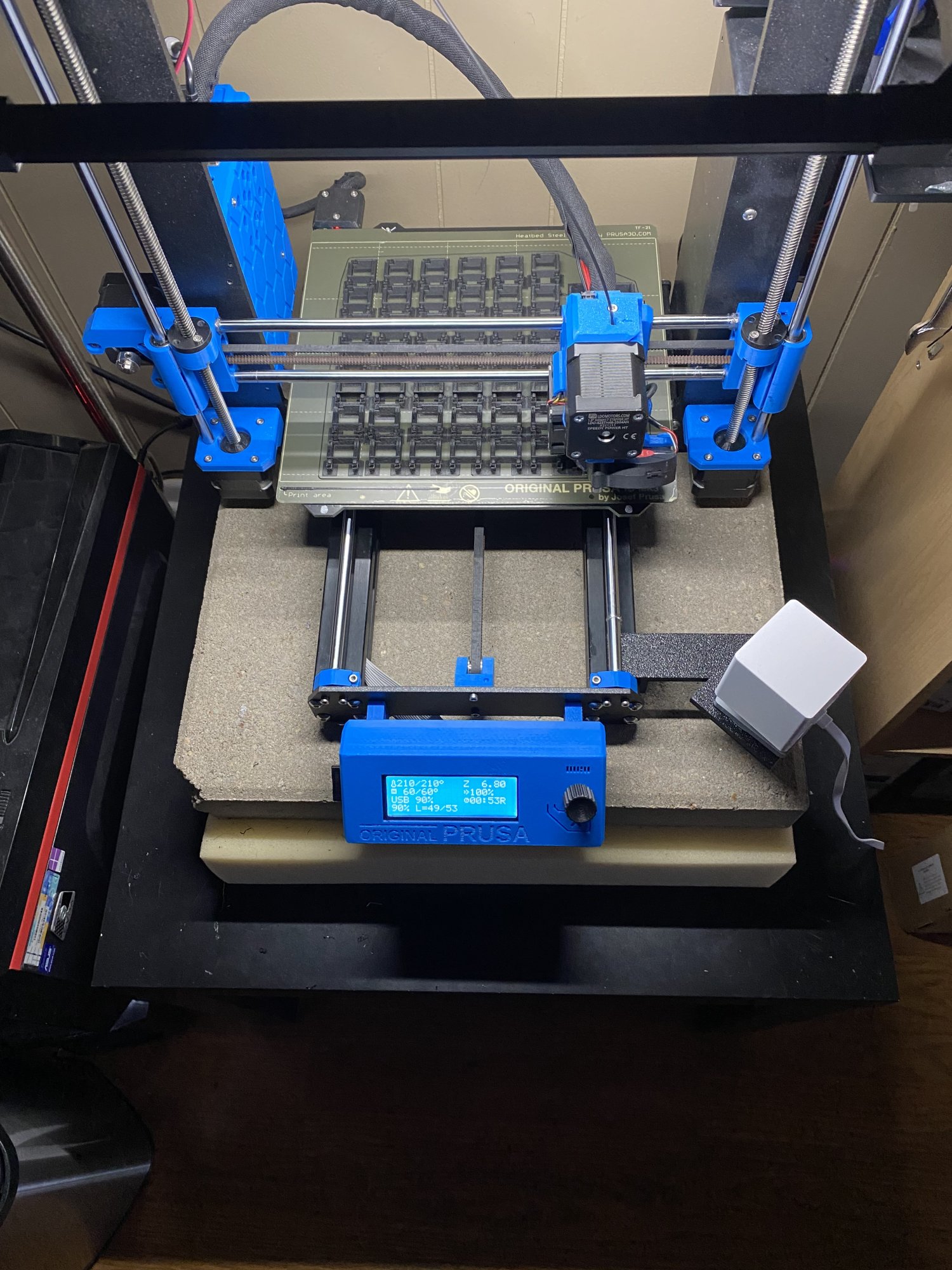

Ive since basically taken the entire thing apart and put it back together straight/properly... the bed was crooked as hell and the guy was apparently printing a ton of stuff on it. It seems like it will be a good first printer. Ive already printed a handful of things as prototypes that I have designed for my business and will be designing/printing some jigs for my fiber laser as well. I paid about $320 for it... I probably couldve bought a better/similar printer brand new but it seemed like a good deal at the time with the Hemera direct drive

Ive since basically taken the entire thing apart and put it back together straight/properly... the bed was crooked as hell and the guy was apparently printing a ton of stuff on it. It seems like it will be a good first printer. Ive already printed a handful of things as prototypes that I have designed for my business and will be designing/printing some jigs for my fiber laser as well. I paid about $320 for it... I probably couldve bought a better/similar printer brand new but it seemed like a good deal at the time with the Hemera direct drive

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)