Zarathustra[H]

Extremely [H]

- Joined

- Oct 29, 2000

- Messages

- 38,847

Hey all,

Based on recommendations in my build thread, I decided to start a new thread of this.

This is what my coolant looked like when I just filled it:

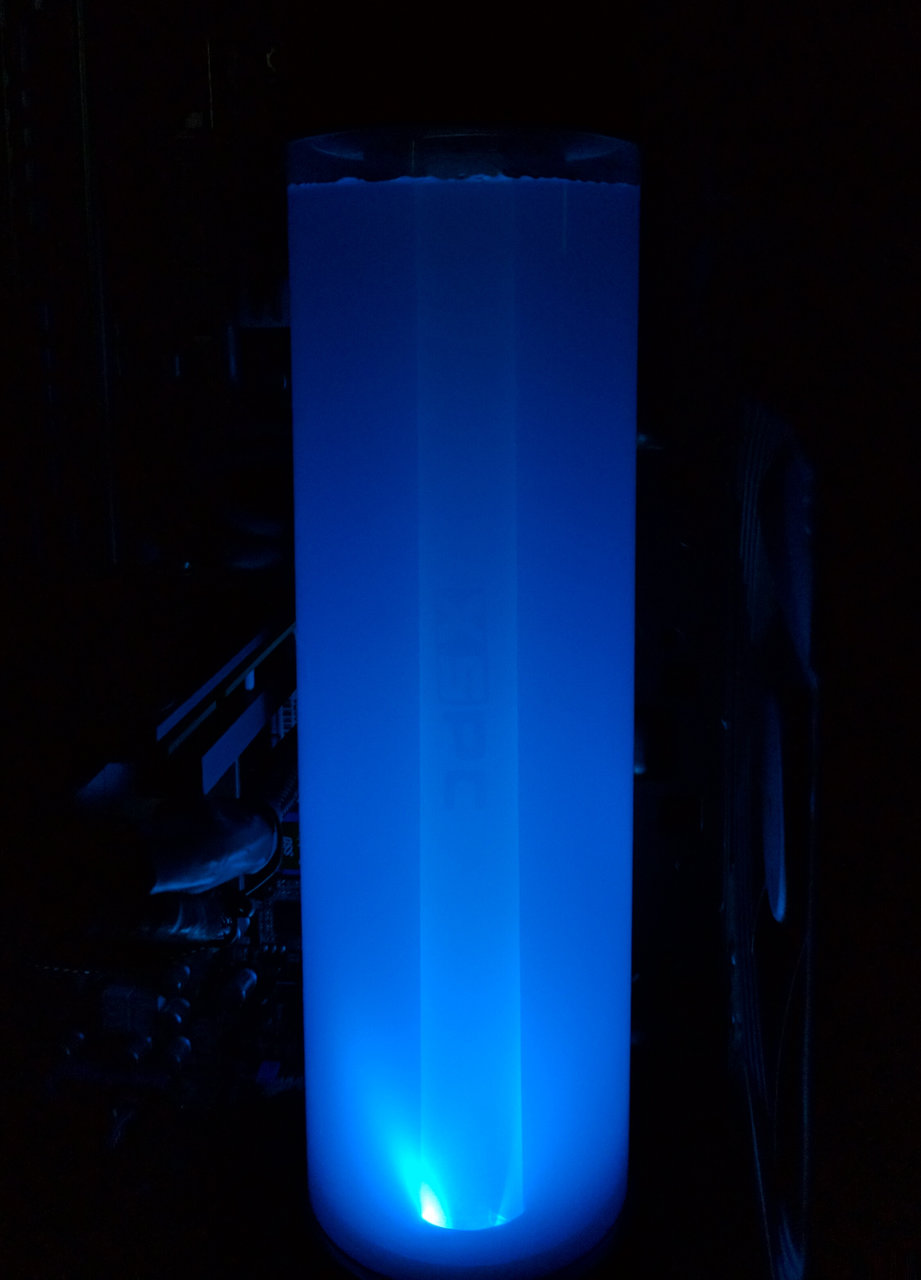

And this is now, only three weeks later.

Before starting my build, I thoroughly cleaned out the radiators with boiling distilled water, rinsing and shaking the inside of each radiator 10 times.

Once I completed my build, I used the Sysprep solution included with the tubing to flush out the system, and perform my leak test as recommended by Primochill.

After this I drained my loop, filled it with plain distilled water and flushed it for a few hours to get the Sysprep out.

After draining again, I then mixed the concentrated EKoolant (one UV blue bottle, two clear bottles) to make 3L total of coolant, and filled my loop. Everything appears to be working great, but I am a little concerned that it already looks this cloudy after only 3 weeks of use.

Is this normal, or should I be concerned?

I have read that cloudiness is common due to plasticizer leeching from tubing, but I didn't expect it to happen so fast, and I was also under the impression that PrimoChills PrimoFlex Advanced LRT didn't suffer from this problem, at least not as much... it seems awfully soon for this type of issue...

Based on recommendations in my build thread, I decided to start a new thread of this.

This is what my coolant looked like when I just filled it:

And this is now, only three weeks later.

Before starting my build, I thoroughly cleaned out the radiators with boiling distilled water, rinsing and shaking the inside of each radiator 10 times.

Once I completed my build, I used the Sysprep solution included with the tubing to flush out the system, and perform my leak test as recommended by Primochill.

After this I drained my loop, filled it with plain distilled water and flushed it for a few hours to get the Sysprep out.

After draining again, I then mixed the concentrated EKoolant (one UV blue bottle, two clear bottles) to make 3L total of coolant, and filled my loop. Everything appears to be working great, but I am a little concerned that it already looks this cloudy after only 3 weeks of use.

Is this normal, or should I be concerned?

I have read that cloudiness is common due to plasticizer leeching from tubing, but I didn't expect it to happen so fast, and I was also under the impression that PrimoChills PrimoFlex Advanced LRT didn't suffer from this problem, at least not as much... it seems awfully soon for this type of issue...

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)