erek

[H]F Junkie

- Joined

- Dec 19, 2005

- Messages

- 10,875

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

OP, fix your thread title.

I think a dab of solder has too low resistance compared to the liquid metal and the card realizes something is up.It has been a long time since I did a voltage mod but why go through the trouble with the liquid metal? Wouldn't a blob of solder be alot less hasle?

It has been a long time since I did a voltage mod but why go through the trouble with the liquid metal? Wouldn't a blob of solder be alot less hasle?

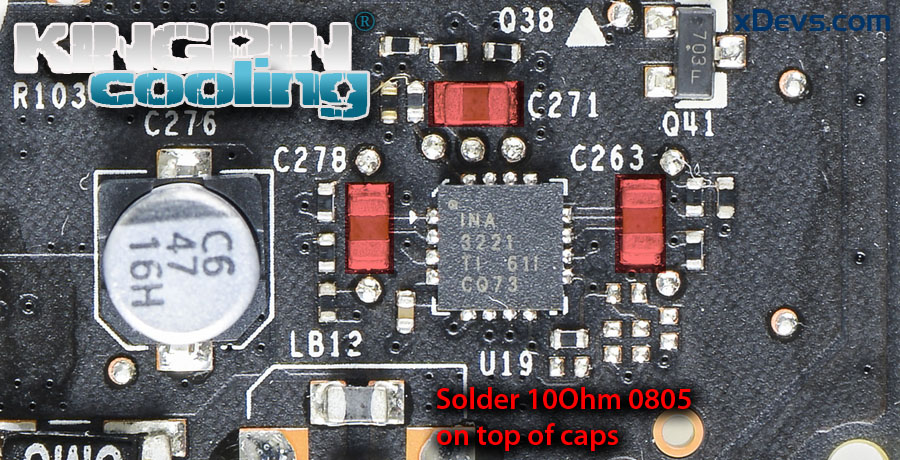

Note that earlier version of this guide incorrectly mentioned need to short RS1, RS2, RS3. This is wrong, and will cause card clock to lock at 135MHz. Do not short shunt resistors themselves, but add resistors like shown on photo below. Sorry for confusion.