Finally got my Murdermod sleeving ... big ups to Nils for putting up with all my emails. So I'm a total noob at this sleeving stuff but all the photos you guys are posting with the slick Murdermod sleeving got me pumped to try it out. So this will be my own little noobian sleeve thread documenting my progress and whether I burn my fingers off with this heat gun I've never actually used.

Behold, das bling ...

And you gotta respect the guy who knows what a "ronin" is ...

The main tools ... yes, I know, that's one phallic lookin heat gun but it was cheap and I think it will work ...

And here is the setup I'll be sleeving (details in my sig below) ...

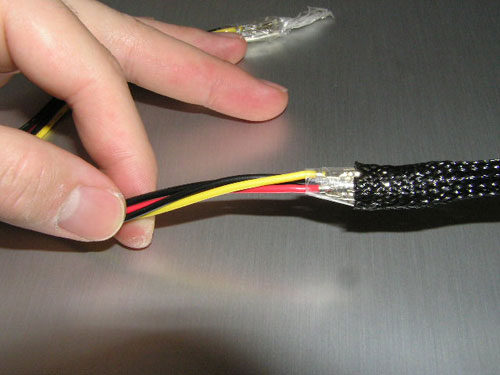

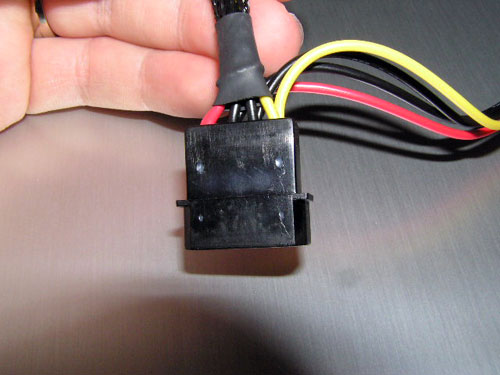

Yes ... you'll notice on some of the wires (not the ATX power cable) I'd taken a stab at some sleeving using some off the shelf crapness. It's quite ugly, I know.

Yup, it's a Scout ...

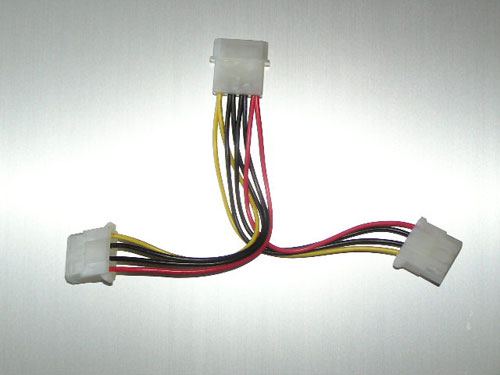

So I thought I'd start off easy with some SATA cables.

I had done all my SATA cables already with the cheapy sleeving so I'm somewhat familiar with how to do it. I'm hoping this will give me some familiarity with how the Murdermod stuff works without getting bogged down with removing and keeping track of pins. I'm thinking of reversing the HDs so that the SATA cables can be shown off in all their sleeving glory.

Behold, das bling ...

And you gotta respect the guy who knows what a "ronin" is ...

The main tools ... yes, I know, that's one phallic lookin heat gun but it was cheap and I think it will work ...

And here is the setup I'll be sleeving (details in my sig below) ...

Yes ... you'll notice on some of the wires (not the ATX power cable) I'd taken a stab at some sleeving using some off the shelf crapness. It's quite ugly, I know.

Yup, it's a Scout ...

So I thought I'd start off easy with some SATA cables.

I had done all my SATA cables already with the cheapy sleeving so I'm somewhat familiar with how to do it. I'm hoping this will give me some familiarity with how the Murdermod stuff works without getting bogged down with removing and keeping track of pins. I'm thinking of reversing the HDs so that the SATA cables can be shown off in all their sleeving glory.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)