Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DAN HSLP-48: A powerful sub 50mm heatsink

- Thread starter dondan

- Start date

That looks really nice!Today I god a feedback from Noctua. Currently they are validating if a heatsink is possible with their current rentention kit. They send me a drawing based on a NH-L12 with 4x8mm heatpipes and the dimensions of my finlayout.

Furthermore I made a little change on my current design. I moved the complete surface 4mm more to the back. So the surface will be the same but the total dimensions of the heatsink is smaller.

AlbinoWolf

n00b

- Joined

- Feb 22, 2017

- Messages

- 39

Wait so are both Noctua & Thermalright interested?

Wait so are both Noctua & Thermalright interested?

even better for us! direct contact heatpipes, air optimized fans, easy mounting, super dense fin arrays, precision tolerance, black copper finish, etc. all those available now!

dondan

[H]ard|Gawd

- Joined

- Apr 15, 2013

- Messages

- 1,751

About how many milimeters are we talking?

S4 Mini fits max 45mm CPU Cooler. So you would be cutting it by 3mm.About how many milimeters are we talking?

S4 Mini fits max 45mm CPU Cooler. So you would be cutting it by 3mm.

Eyeballing the fin height, I'd say that reducing it by 3mm is equivalent to roughly 15% reduction in surface area. I wouldn't be very happy with that.

Don't speculate without actual information. Let the expert decide if the reduction is feasible.Eyeballing the fin height, I'd say that reducing it by 3mm is equivalent to roughly 15% reduction in surface area. I wouldn't be very happy with that.

This post by CubanLegend shows there's 9mm gap when L9i is installed in S4 mini.

Which if we add to the 37 mm on paper for the L9i, means the s4 mini has in practical terms for that specific example, a total of 46mm of height. Without the fan right up against the panel means the DanSink would need to be 2-3mm shorter.

Kinda trading perfection in the DanA4 for a wider marketshare... the call will be based on how well prototypes can perform, if this is a variant that ends up being tested.

Kinda trading perfection in the DanA4 for a wider marketshare... the call will be based on how well prototypes can perform, if this is a variant that ends up being tested.

Without the fan right up against the panel means the DanSink would need to be 2-3mm shorter

Fan goes under the fins, I don't see why the fins couldn't be touching the panel. anyway, that's 46mm vs 48.

Fan goes under the fins, I don't see why the fins couldn't be touching the panel. anyway, that's 46mm vs 48.

I think we are agreeing that the fins can and should be hard up against the side panel.

2-3 mm is likely to be the minimum reduction in height we need to give for it to fit the S4 too.

3mm in case we need room for manufacturing tolerances for the heatsink and the case, but no more because we want have the fins hard up against the side panel and maximise height for the dancase.

I would maximise height where possible as it allows the fan to breathe better, especially where the fan is pulling air from the mobo and out through the heatsink. It would be in this orientation where the 2mm height reduction might make a difference in performance by slightly reduced airflow.

Airgap between fan and cpublock is only 5mm, you really cant squish that much.48 or 50 mm. doesn't matter. make it 50 and then you can squish it down to fit your other cases. (as long as the fan can still fit below)

not elegant, but best cooling performance for everyone with a little DIY involved

CubanLegend

n00b

- Joined

- May 22, 2014

- Messages

- 42

I mean it is one of the best z270 Mini-ITX boards out there with the dual M.2... So any asking for compatibility might have some merit to their requests, lol. Alternatively they could try and remove the VRM heatsinks on the z270i STRIX to fit a larger CPU cooler.INB4 everyone complains its not asus strix z270i compatible.

I stand by my measurements. I'd really like a competitor to the LP53 and the NH-L9i that can fit inside the S4 mini, if it's a FULL COPPER part.This post by CubanLegend shows there's 9mm gap when L9i is installed in S4 mini.

My LP53 should arrive next week and I'll be trying to fit it on the z270i with the heatsink fins parallel to the RAM for optimal cooling to compare against the NH-L9i, inside the S4 mini.

If this HSLP-48 can fit inside the S4 and on top of the z270i STRIX, and it turns out it cools better than both the NH-L9i and the LP53 (whether full-copper or not), then i'll seriously consider it going in my case.

Last edited:

Just want to inform Dan that I would be interested in a greater heatsink if the project succeeds with its goals.

Unfortunately I am one of them....you know...one of those Asus Strix z270I owners so that would be a requirement from my side, don't see me replacing that MB anytime soon.

I have not understod the issue but is it the M.2 heatsink or that other one facing the ports?

If it is the M.2. heatsink could we potentionally run without it, don't know who that would affect the M2 though?

Unfortunately I am one of them....you know...one of those Asus Strix z270I owners so that would be a requirement from my side, don't see me replacing that MB anytime soon.

I have not understod the issue but is it the M.2 heatsink or that other one facing the ports?

If it is the M.2. heatsink could we potentionally run without it, don't know who that would affect the M2 though?

Pusher of Buttons

[H]ard|Gawd

- Joined

- Dec 6, 2016

- Messages

- 1,924

Pick one motherboard and one GPU to support, CNC the entire case out of a monolithic block of silver to precisely match all protrusions, and a thin layer of non-conductive thermal compound. Duh, it's easy, you guys make this seem so hard.

*Beyond my (probably not very) amusing comment....been following quietly following this project for a long time. Fascinated by it....I don't have the $$ to throw at it....but if I did I'd be a customer.

*Beyond my (probably not very) amusing comment....been following quietly following this project for a long time. Fascinated by it....I don't have the $$ to throw at it....but if I did I'd be a customer.

Last edited:

dondan

[H]ard|Gawd

- Joined

- Apr 15, 2013

- Messages

- 1,751

I can only say it again, I will not make the heatsink smaller to only support the Strix. Furthermore I will not make it 3mm thinner to support the S4. The heatsink will be only a success if it is mutch better as the LP53. So we need every degree and every milimeter. The minimum order quantity will be mutch higher as for the A4-SFX. I think the Kickstarter campaign is more than 6 month away. So on that time you will have it in your hands there will be newer boards then the Strix.

Julio Espinosa

Weaksauce

- Joined

- Feb 1, 2017

- Messages

- 71

I can only say it again, I will not make the heatsink smaller to only support the Strix. Furthermore I will not make it 3mm thinner to support the S4. The heatsink will be only a success if it is mutch better as the LP53. So we need every degree and every milimeter. The minimum order quantity will be mutch higher as for the A4-SFX. I think the Kickstarter campaign is more than 6 month away. So on that time you will have it in your hands there will be newer boards then the Strix.

This could be repetitive.

Is the Asrock Fatal1ty mini ITX Z270 the only mini ITX motherboard with Thunderbolt 3? I would love to use your CPU cooler with that one! (and with the A4-SFX when available)

CubanLegend

n00b

- Joined

- May 22, 2014

- Messages

- 42

Another note about my measurements in the post.This post by CubanLegend shows there's 9mm gap when L9i is installed in S4 mini.

I measured 3 things:

09mm - from top of NF-A9x14-PWM to start of S40mini Side-panel.

52mm - from the base of the mobo (z270i STRIX) to the start of the S4-Mini sidepanel

42mm - from the base of the mobo to the top of the NF-A9x14-PWM on top of it's NH-L9i cooler...

How is the NH-L9i only 37mm on paper? From what point does it measure?

So IF there's a 9mm gap between the top of the NH-L9i HSF & the S4-mini Side panel... does that leave room for this HSLP-48?

From what point does dondan measure the Z height of the cooler? from base of mobo up to top of cooler, or from bottom of CPU plate up to the top of the cooler?

Last edited:

Veritas187

Weaksauce

- Joined

- Feb 9, 2017

- Messages

- 84

https://www.newegg.com/Product/Prod...153&cm_re=Evercool_hpl-_-35-119-153-_-Product

Anyone ever used this? Reviews seem to be good maybe change out the fan

Anyone ever used this? Reviews seem to be good maybe change out the fan

Have you seen the Calyos NSG-S0 / Official site?Pick one motherboard and one GPU to support, CNC the entire case out of a monolithic block of silver to precisely match all protrusions, and a thin layer of non-conductive thermal compound. Duh, it's easy, you guys make this seem so hard.

*Beyond my (probably not very) amusing comment....been following quietly following this project for a long time. Fascinated by it....I don't have the $$ to throw at it....but if I did I'd be a customer.

dondan

[H]ard|Gawd

- Joined

- Apr 15, 2013

- Messages

- 1,751

Update:

I had a conversation with Noctua they told me, that four 6mm heatpipes is more than enough. As you can see the LP53 has only two heatpipes an work very well. They said it is better to have more surface what we get if we remove two pipes. So here is my updated design:

I had a conversation with Noctua they told me, that four 6mm heatpipes is more than enough. As you can see the LP53 has only two heatpipes an work very well. They said it is better to have more surface what we get if we remove two pipes. So here is my updated design:

XstreamHard

n00b

- Joined

- Jan 21, 2017

- Messages

- 60

What about direct touch though?

dondan

[H]ard|Gawd

- Joined

- Apr 15, 2013

- Messages

- 1,751

I will discuss this with them.

Shaav

Limp Gawd

- Joined

- Sep 28, 2011

- Messages

- 163

That cooler looks perfect. I would fund that!

tripheo2410

n00b

- Joined

- Mar 5, 2017

- Messages

- 23

So nice I died. Definitely would fund that

Hotshot619

n00b

- Joined

- Oct 2, 2016

- Messages

- 35

I'm really looking forward to the prototyping phase. I'd really love to see if with some modding how a Prolimatech Ultra Sleek 12 would fair on this full copper design.

Can't wait to get this in a A4!

Can't wait to get this in a A4!

AlbinoWolf

n00b

- Joined

- Feb 22, 2017

- Messages

- 39

I think it is more of a compromise:

Heatpipes provides heat transfer,

surface area provides heat dissipation.

You want to optimize both ~> and I think that is what Noctua and Dan meant when they said 4 heatpipes is enough.....

Also when was this ever about the cost?

Heatpipes provides heat transfer,

surface area provides heat dissipation.

You want to optimize both ~> and I think that is what Noctua and Dan meant when they said 4 heatpipes is enough.....

Also when was this ever about the cost?

I think it is more of a compromise:

Heatpipes provides heat transfer,

surface area provides heat dissipation.

You want to optimize both ~> and I think that is what Noctua and Dan meant when they said 4 heatpipes is enough.....

Also when was this ever about the cost?

This.

Add more heatpipes and you're removing surface area on the fins. One question, though, why 6mm rather than 8mm? It seems like it would offer better conduction with a very minimal increase in surface area.

Hello,

First i`m not expert in thermodynamics and so, but i here is my opinion.

Four heatpipe is ok: But if it is direct contact i think is better to use vapor chamber (Multi-directional heat spreading versus linear heat transport). Only concern is the price.

What you think, about this design:

First i`m not expert in thermodynamics and so, but i here is my opinion.

Four heatpipe is ok: But if it is direct contact i think is better to use vapor chamber (Multi-directional heat spreading versus linear heat transport). Only concern is the price.

What you think, about this design:

Code:

vc1,vc2 - vapor chambers

h1,h2 - heatpipes

TOP VIEW

╔====╗███╔====╗

=║====║███║====║=

=║====║███║====║= fins

=║====║███║====║=

=║====║███║====║=

=h1==h1███h2==h2=

vc1vc2

FRONT VIEW

-------vc1-------

░h1░░░h1░h2░░░h2░

-------vc2-------

====fan====

[vc2]

[vc1]

[cpu]

SIDE VIEW

vc1_______________

||||| fins ||||| │ <-----h1h2

vc2¯¯¯¯¯¯¯¯¯¯¯¯│ │

====fan==== │ │

vc2_____│ │

vc1_______│

[cpu]dominathan

Weaksauce

- Joined

- Feb 23, 2016

- Messages

- 85

I think Noctua knows what they're talking about

tripheo2410

n00b

- Joined

- Mar 5, 2017

- Messages

- 23

More heatpipes does not mean better performance, you can look to those heatsinks from scythe, they are absolutely full of heatpipes and super big but performance does not go near Silverarrow or Noctua nhd15 etc...whats important is not being "adequate", if we want to OC our cpus to 5ghz we need MORE THAN "ENOUGH". 5 or 6 heat pipes. cost cutting is LAME. 8mm, 6 HEATPIPES. NO COMPROMISE.

NO COMPROMISE

Yay, 4 heatpipes  Very happy with that! Should give more surface area for cooling for the quieter system I'm looking to use it for.

Very happy with that! Should give more surface area for cooling for the quieter system I'm looking to use it for.

This is looking really nice now, even if I don't need one, I will buy anyway as its so pretty in its elegance and simplicity.

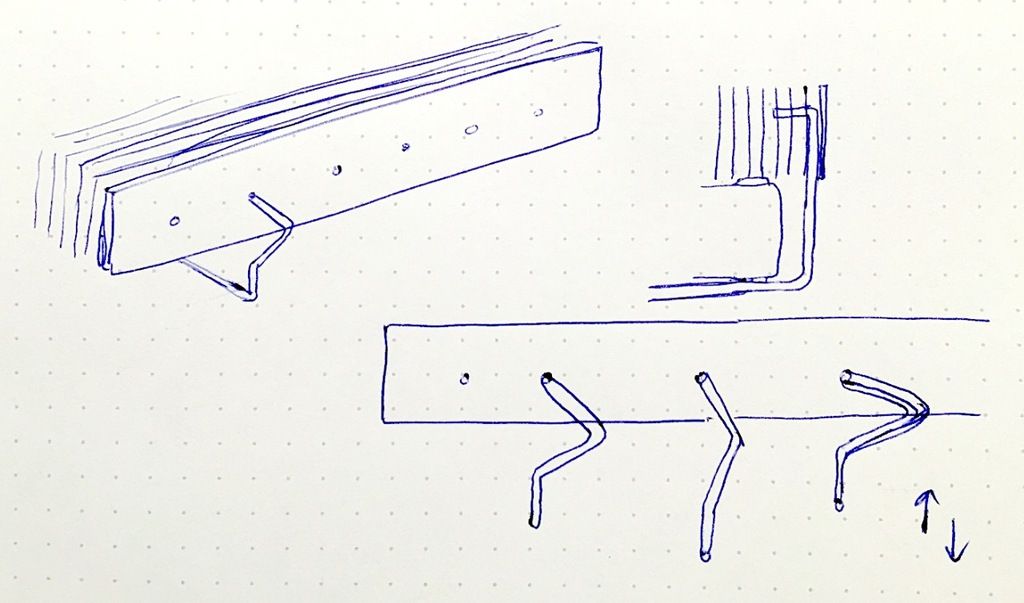

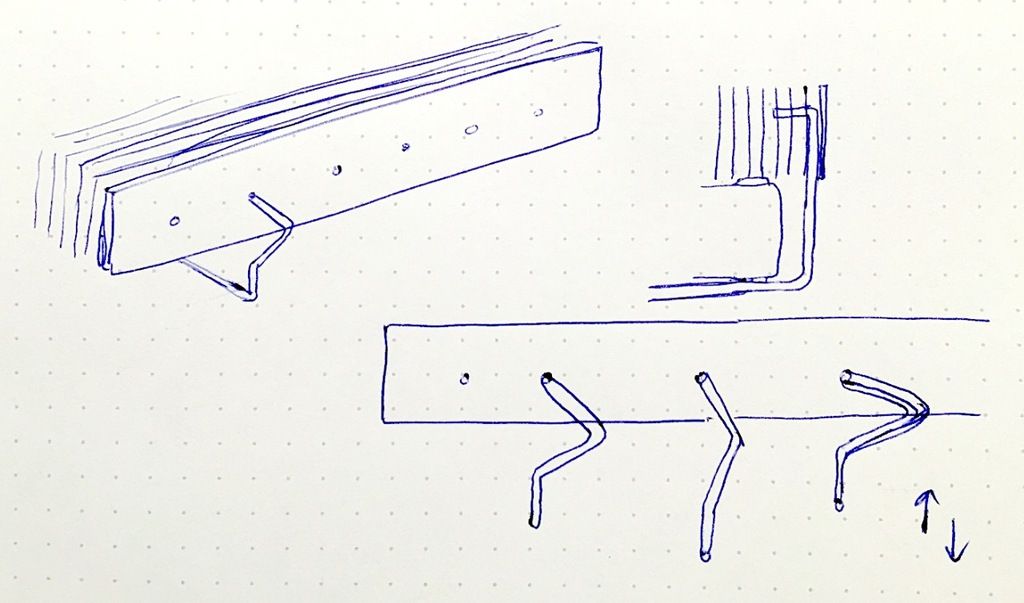

Just want to see Z bends in the fan clips, ill roughly sketch up something to better explain myself. Of course the thinkness of the wires is too heavy, but the idea is there.

By tweaking of the bend, we can change the length of the wire to fit various fan thicknesses, as well as adjusting the pre-load tension to apply the right tension for the various fans out there.

This would make the heatsink compatible with a variety of thicknesses and therefore a wider variety of fans;

12mm thick Scythe 120mm slim fan

14mm thick Noctua 92mm A9-14

14.8mm thick Gelid Slim UV 120mm fan

15mm slim fans (numerous examples)

(and additional thickness if a rubber layer is added for noise dampening, although this seems to be a part of the heatsink design already)

This is looking really nice now, even if I don't need one, I will buy anyway as its so pretty in its elegance and simplicity.

Just want to see Z bends in the fan clips, ill roughly sketch up something to better explain myself. Of course the thinkness of the wires is too heavy, but the idea is there.

By tweaking of the bend, we can change the length of the wire to fit various fan thicknesses, as well as adjusting the pre-load tension to apply the right tension for the various fans out there.

This would make the heatsink compatible with a variety of thicknesses and therefore a wider variety of fans;

12mm thick Scythe 120mm slim fan

14mm thick Noctua 92mm A9-14

14.8mm thick Gelid Slim UV 120mm fan

15mm slim fans (numerous examples)

(and additional thickness if a rubber layer is added for noise dampening, although this seems to be a part of the heatsink design already)

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)