Red Squirrel

[H]F Junkie

- Joined

- Nov 29, 2009

- Messages

- 9,211

I'm thinking of buying a bunch of these:

http://www.monoprice.com/products/p...=10516&cs_id=1051602&p_id=8629&seq=1&format=2

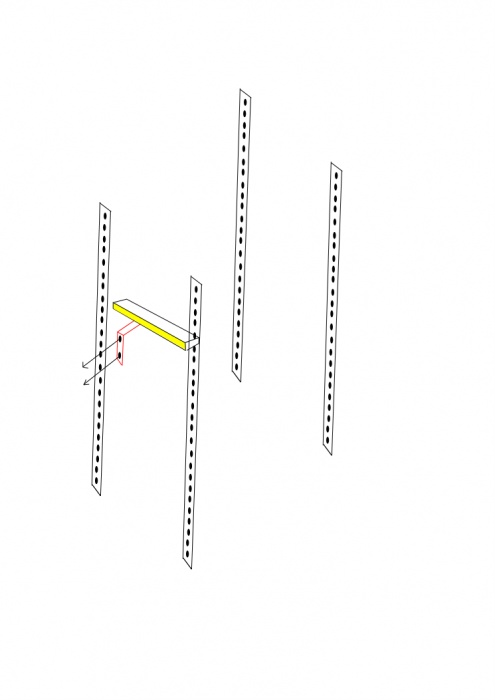

To make 1 shelf I would have one at each end of a a 4 post rack and have a piece of plywood spanning both. I would add a 2x4 at the end of the plywood on both shelves so the weight is concentrated at the front of each shelf reducing leverage. My intention is for this shelf to hold several big lead acid batteries, basically car batteries. I never weighed one of those batteries but they're quite heavy, if I had to guess, about 50 pounds. Even though these shelves are only rated at 50 pounds do you think they'll be able to handle more in my planned configuration? Idealy I want this as dense as possible, so probably like 4 batteries per shelf. (I only have 2 right now but future planing)

I got a free server rack, so I will dedicate it towards power backup. It has side panels, doors and all.

http://www.monoprice.com/products/p...=10516&cs_id=1051602&p_id=8629&seq=1&format=2

To make 1 shelf I would have one at each end of a a 4 post rack and have a piece of plywood spanning both. I would add a 2x4 at the end of the plywood on both shelves so the weight is concentrated at the front of each shelf reducing leverage. My intention is for this shelf to hold several big lead acid batteries, basically car batteries. I never weighed one of those batteries but they're quite heavy, if I had to guess, about 50 pounds. Even though these shelves are only rated at 50 pounds do you think they'll be able to handle more in my planned configuration? Idealy I want this as dense as possible, so probably like 4 batteries per shelf. (I only have 2 right now but future planing)

I got a free server rack, so I will dedicate it towards power backup. It has side panels, doors and all.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)