Hello everyone! New here, it looks like there are lots of smart peeps in this forum so I figured this would be the best place to ask for some help, if anyone is willing to.

So, I got this card from an auction sale. 50 bucks CAD got me the card, an i7 7700k with a strix board, and a bunch of wires and plugs and other goodies. Unfortunately the card doesn't work, but I'm willing to learn some things to see if it's worth it, or even possible to revive the card. I'm not much of an electronics guy. I know more than my friends, I play with arduinos and work on my car with electrical stuff, but 90% of the time I don't understand WHY it works, just that it does. So while I'm not a total newbie, please forgive me for any dumb questions, I'll try my best to limit how many I ask.

Anyway, here are the symptoms/notables

Things I've "tested" or noticed. Not sure how much of this is valuable info, but maybe it'll help out.

I don't really know where to start looking from here on. Some guidance would be greatly appreciated. I'm not expecting to bring this back to life, but I may as well try, and use it as a learning experience. I'm still happy with my purchase regardless, as I still got enough out of it. I'm just so surprised how a card so clean is so dead. Would this be a mining card? I'm assuming theres a good chance, as a good miner would probably have great ventilation which would explain the lack of caked on dust.

Thanks all for reading this. I can provide pics when needed.

So, I got this card from an auction sale. 50 bucks CAD got me the card, an i7 7700k with a strix board, and a bunch of wires and plugs and other goodies. Unfortunately the card doesn't work, but I'm willing to learn some things to see if it's worth it, or even possible to revive the card. I'm not much of an electronics guy. I know more than my friends, I play with arduinos and work on my car with electrical stuff, but 90% of the time I don't understand WHY it works, just that it does. So while I'm not a total newbie, please forgive me for any dumb questions, I'll try my best to limit how many I ask.

Anyway, here are the symptoms/notables

- card plugged into any mobo PCIE trips the PSU protection

- card not plugged into PCIE but plugged in with 8 pin doesn't trip PSU, at least not instantly that I saw

- the white and red led light to sense the 8 pin being plugged in works correctly.

- card is extremely clean. Can't even find any caked on dust deep in the heatsink.

- card also came with rubber sleeves for the PCIE and the mounting bracket, as well as caps for the display ports. Doesn't mean much, but it's clean as heck

Things I've "tested" or noticed. Not sure how much of this is valuable info, but maybe it'll help out.

- the first 3 12v lane/pin (is it called a lane?) on the PCIE has 1ohm to ground. Which I guess is a short. I have a cheapo mastercraft multimeter.

- the 3.3v lane, fourth from the right most pin, is 160kohm to ground

- the 12v to ground pins on the 8 pin connector are all 50ohm. Doesn't matter what combination.

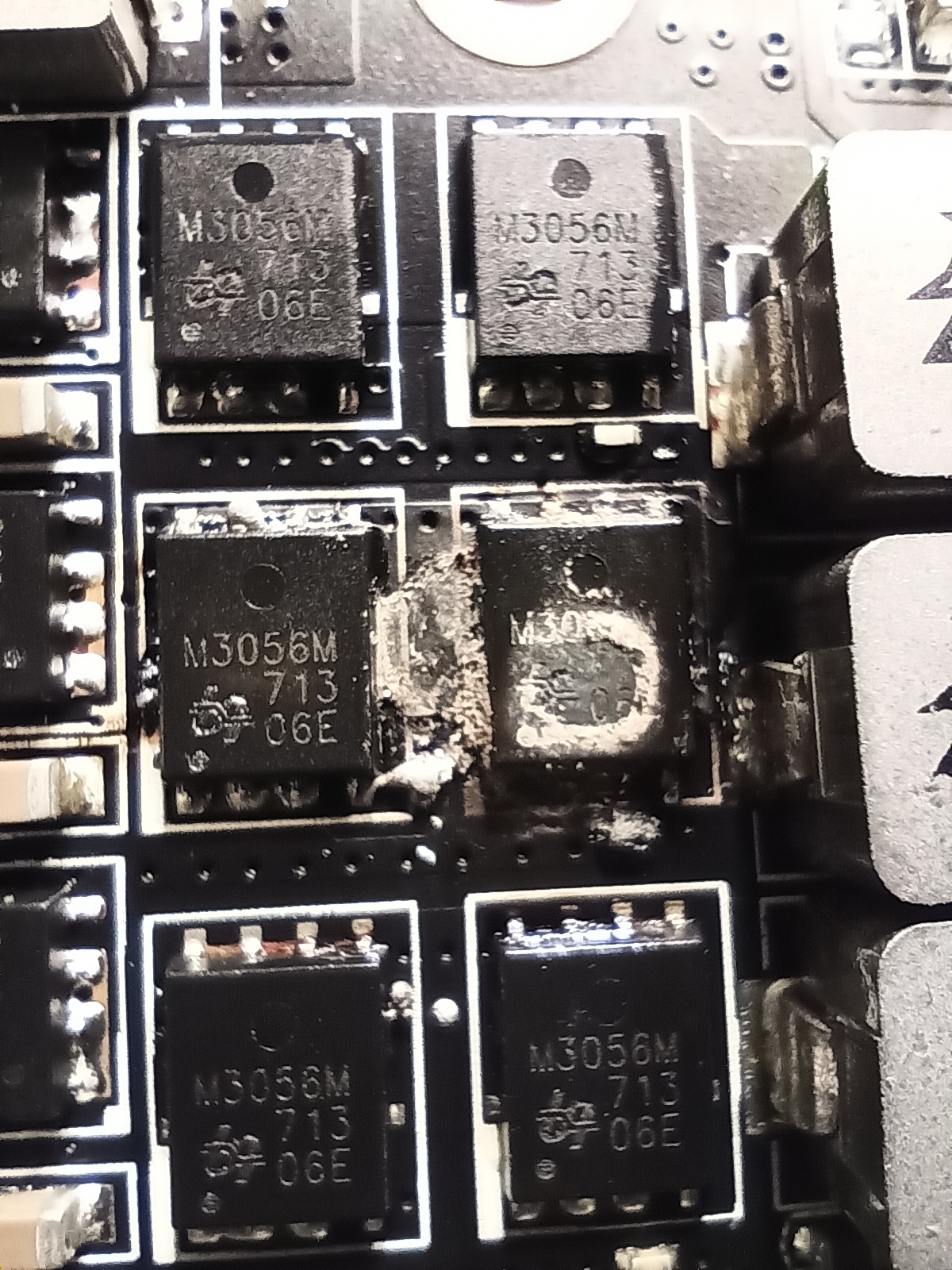

- the 4 MOSFETS near the 8 pin have 3 pins on one side that are bridged together. I have no idea if it's intentional or not, but considering all 4 have that I think probably?

- no burn marks, no clearly broken parts. Which makes life harder.

I don't really know where to start looking from here on. Some guidance would be greatly appreciated. I'm not expecting to bring this back to life, but I may as well try, and use it as a learning experience. I'm still happy with my purchase regardless, as I still got enough out of it. I'm just so surprised how a card so clean is so dead. Would this be a mining card? I'm assuming theres a good chance, as a good miner would probably have great ventilation which would explain the lack of caked on dust.

Thanks all for reading this. I can provide pics when needed.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)