Kattstrumpa

n00b

- Joined

- Oct 9, 2016

- Messages

- 23

My friend with limited knowledge around water cooling want to do a crazy build which I'm not sure I would recommend.

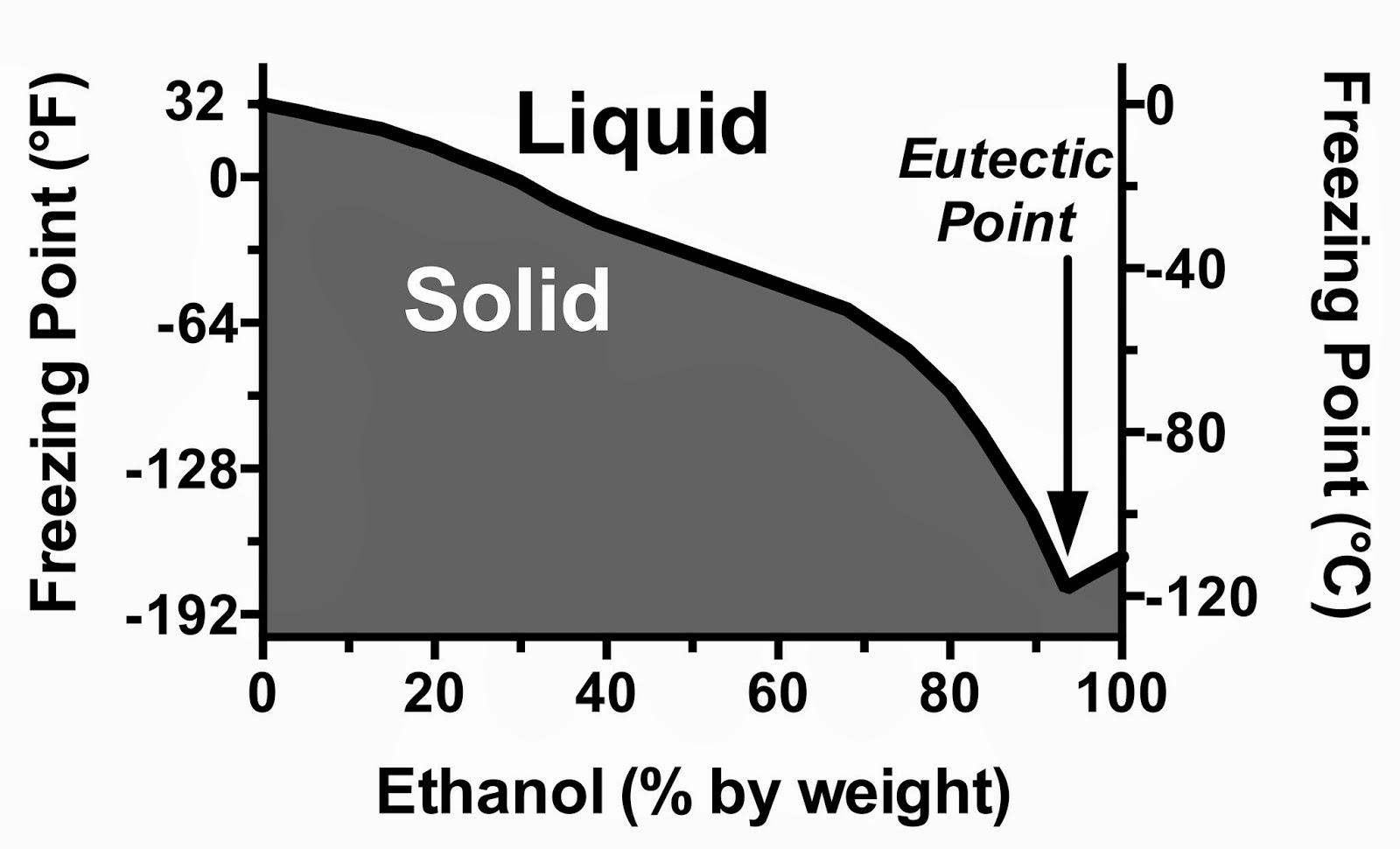

What could be the dangers and issues with this setup: 6x GPU's (!) in a mining setup, 1x random CPU and everything under water blocks. He wants to put everything in one loop which is pretty nuts. I told him put everything in at least two loops. But the most crazy thing is he wants to run everything in copper pipes OUTSIDE and cool everything passively in -30 degrees C cold... I don't know if this is such a good idea. Any one with knowledge around low temperatures and radiators/coolant?

he wants to put glycol (anti freeze) in the loop to prevent freezing. Even if this is possible corrosion might be a huge problem right? Why isn't corrosion a problem in cars, but in water loops running on glycol or anti-freeze?

What could be the dangers and issues with this setup: 6x GPU's (!) in a mining setup, 1x random CPU and everything under water blocks. He wants to put everything in one loop which is pretty nuts. I told him put everything in at least two loops. But the most crazy thing is he wants to run everything in copper pipes OUTSIDE and cool everything passively in -30 degrees C cold... I don't know if this is such a good idea. Any one with knowledge around low temperatures and radiators/coolant?

he wants to put glycol (anti freeze) in the loop to prevent freezing. Even if this is possible corrosion might be a huge problem right? Why isn't corrosion a problem in cars, but in water loops running on glycol or anti-freeze?

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)