- Joined

- May 18, 1997

- Messages

- 55,634

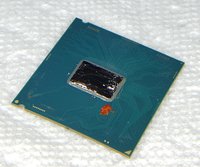

7600K Naked Die Cooling Temperature Follow-Up - Last week we decided to see if we could get our naked Intel Core i5-7600K working in the LGA socket after going through the delidding process. We did in fact get the system functional, but the real goal was to achieve better cooling. This is a quick summation of what exactly we experienced.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)