notarat

2[H]4U

- Joined

- Mar 28, 2010

- Messages

- 2,501

Half a dozen 3D Printers on the other.

*sigh*

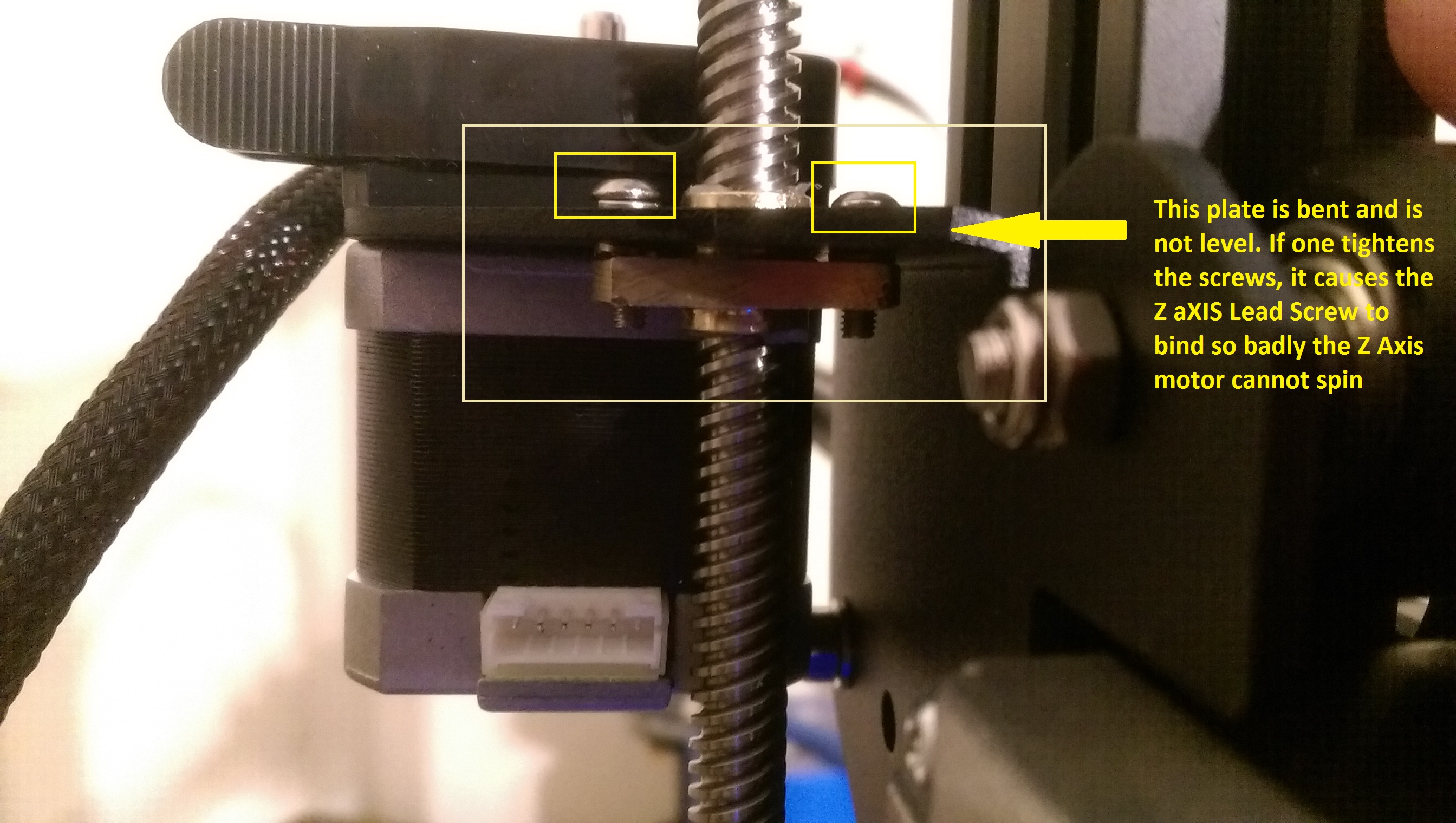

Just ordered a CR-10 Creality 3D Printer, bringing my total to 6. WTF was I thinking?!

Replicator 2

Rostock Max V2

Mono Select Mini

Creator X

Creator Pro

CR-10

/me dumb.

*sigh*

Just ordered a CR-10 Creality 3D Printer, bringing my total to 6. WTF was I thinking?!

Replicator 2

Rostock Max V2

Mono Select Mini

Creator X

Creator Pro

CR-10

/me dumb.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)