Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Print Your Own Intel Delid Tool for Skylake & Kaby Lake @ [H]

- Joined

- May 18, 1997

- Messages

- 55,634

Yes, I have my hands shaved at the same time I get my taint done.Kyle you gotta do more videos, they are always good to watch. On a side note do you shave your hands? ^.^

cageymaru

Fully [H]

- Joined

- Apr 10, 2003

- Messages

- 22,087

Kyle you gotta do more videos, they are always good to watch. On a side note do you shave your hands? ^.^

I don't have hair on my hands.

Somehow I do not have the balls to take a hammer and a piece of 2x4 to my nearly 400 dollar computer piece.

I can just hear my wife now........."you did what.......are you fucking crazy......why don't you just light the money on fire.....it would be quicker...."

I can just hear my wife now........."you did what.......are you fucking crazy......why don't you just light the money on fire.....it would be quicker...."

- Joined

- May 18, 1997

- Messages

- 55,634

LOL! I hear you brother. I will say this, most of the folks that go into "this business" to get free hardware, and there were plenty, are mostly gone now.Well of course you did, it's your profession. This is a work related expense, thus it's fully justifiable for you.

The issue is that I can only write off so much, let alone justify that sort of fun with five girls in their teens.

In short.

I'm jealous.

Really, really jealous.

Waiting for the TIM to arrive, parts printed, but wondering if there shouldn't be some type of relid tool also; to hold pressure on the lid as the Permatex stuff dries. I guess I could just use the bottom piece and something to press on the lid and c-clam it again, but I dunno... Maybe I'm overthinking it, a binderclip might do the same.... Or is there actually a 3d printed relid tool? Found nothing on Thingiverse

- Joined

- May 18, 1997

- Messages

- 55,634

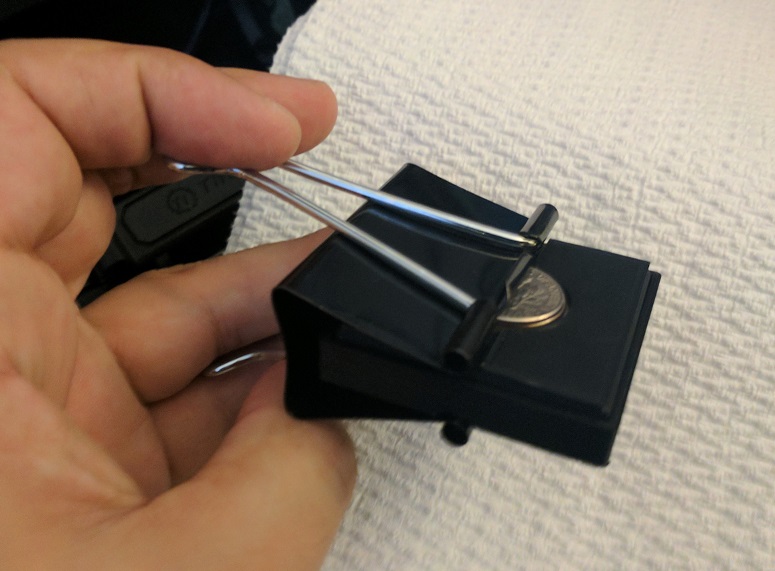

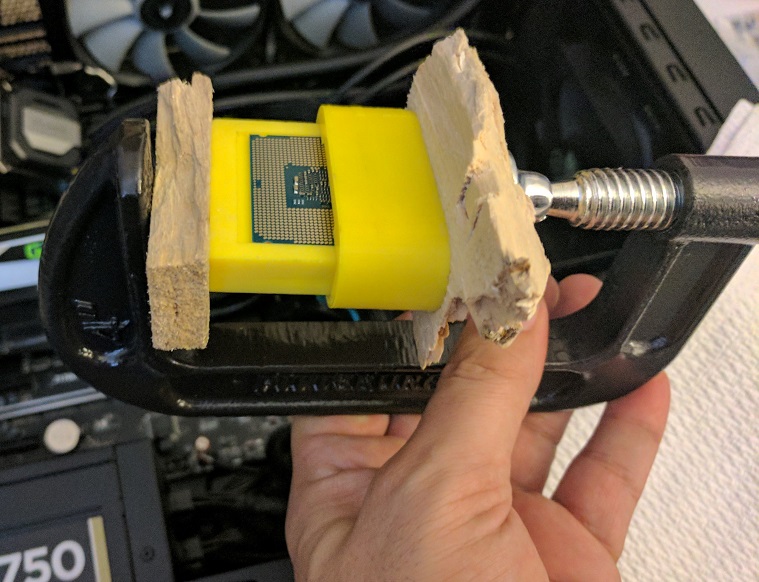

A binder clip that very strong might be a good solution, but there is a drawback, but it could be remedied with changing how the tool is made. I have been looking to do a relid video today so this has been on my mind. I think if you use the inner portion of the delid tool and then clamp down onto that so the substrate is supported on the edges, it should give you a good seal, unless you use too much clamping force. As shown in the picture, the leading edge of the substrate is not supported and if you use too much pressure it gaps there.Waiting for the TIM to arrive, parts printed, but wondering if there shouldn't be some type of relid tool also; to hold pressure on the lid as the Permatex stuff dries. I guess I could just use the bottom piece and something to press on the lid and c-clam it again, but I dunno... Maybe I'm overthinking it, a binderclip might do the same.... Or is there actually a 3d printed relid tool? Found nothing on Thingiverse

If you added material there on that edge, you could remedy that issue and make it awesome for relidding.

- Joined

- May 18, 1997

- Messages

- 55,634

My experiences have shown that sealing it down very well gives better temps. YMMV.I have another idea for relidding and resealing. Why not just use the cpu socket clamp for mounting pressure ? Should be enough, if one want's to reseal the IHS when new TIM and "insert you own choise of sealant here" has been applied.

Myself I don't reseal, just apply CLU on the core and put the bare CPU back in the socket, then place the IHS correctly on top an clamp it down in the socket and im good to go. Plus side of this is that there will be no sealant to interfere with the core/IHS contact pressure. One could argue the mounting pressure would be as [H]ard as it could get.

Waiting for the TIM to arrive, parts printed, but wondering if there shouldn't be some type of relid tool also; to hold pressure on the lid as the Permatex stuff dries. I guess I could just use the bottom piece and something to press on the lid and c-clam it again, but I dunno... Maybe I'm overthinking it, a binderclip might do the same.... Or is there actually a 3d printed relid tool? Found nothing on Thingiverse

You may check that : https://www.youmagine.com/designs/intel-sky-kaby-lake-relid-tool

- Joined

- May 18, 1997

- Messages

- 55,634

I think it would be pretty easy to design a relid tool into the current design besides the clamp. But most folks don't really need that clamp most likely since you could use your own or stick it under the couch leg for the night.

P4B

Limp Gawd

- Joined

- Apr 28, 2012

- Messages

- 336

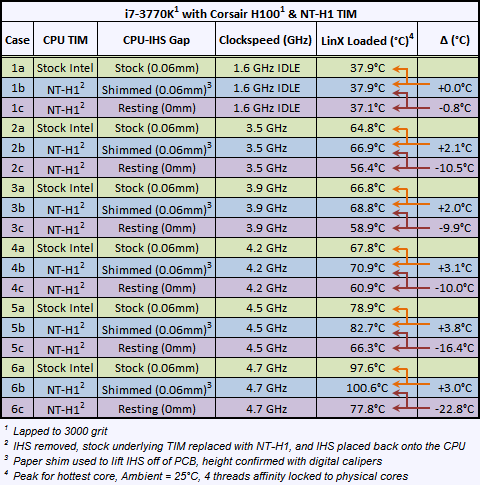

So we already get improvements from just replacing the stock thermal paste and adding a bigger heat sink and fans. Just how much more is this giving us on top of all of that? I have seen one video but i dont remember if they gave a good enough review.

Spacy9

Scotch is my Lord and Savior

- Joined

- Oct 13, 2000

- Messages

- 1,813

That was awesome! Glad I sent you two

Yes! then we can crush a 7700k @ 2 million FPSKyle, do you have access to something like a hydraulic press?

Shotglass01

[H]ard|Gawd

- Joined

- Aug 26, 2005

- Messages

- 1,992

That was friggen great! Feels very Mythbusters like. Wouldn't be surprised if Adam and Jamie show up to help you delid with a bullet, or better yet, explosives.

A competitive AMD is our only hope for that one.Has anyone tried suggesting to Intel to put quality TIM in their $400 products? Seems like an easier fix than all this mess.

Fifth Horseman

Limp Gawd

- Joined

- May 5, 2000

- Messages

- 455

Is that setup ESD safe?  j/k

j/k

Quick idea I had. Instead of using a hammer and a block of wood, use a tourniquet. Place a 2" strip of cloth along the moving axis of the delid tool and use something (a pencil, screwdriver, a butterknife, whatever) to twist the fabric so it squeezes the lid off of the CPU. The cloth from an old t-shirt should be strong enough for this.

Quick idea I had. Instead of using a hammer and a block of wood, use a tourniquet. Place a 2" strip of cloth along the moving axis of the delid tool and use something (a pencil, screwdriver, a butterknife, whatever) to twist the fabric so it squeezes the lid off of the CPU. The cloth from an old t-shirt should be strong enough for this.

Shotglass01

[H]ard|Gawd

- Joined

- Aug 26, 2005

- Messages

- 1,992

Damn it Kyle! Stop tempting me with these delidding techniques. Must resist temptation to mess around with the CPU...

Right? I'm going to be building a new system with a 7700k. It's taking all my resistance not to delid. At least, not right now.

Just built my 7700k and I am tempted as well, my buddy has a new 3d-printer and I dunno for how much longer I can resist

Making a few test prints first so we get used to the 3d stuff...its all new for us.

Relidding somehow holds me back... would be nice if it was built-in into the tool.

Kyle, great videos, great site, you damn rock !!!

Making a few test prints first so we get used to the 3d stuff...its all new for us.

Relidding somehow holds me back... would be nice if it was built-in into the tool.

Kyle, great videos, great site, you damn rock !!!

I got one from spacey9 as well. sadly it didnt fit my ivy bridge the normal way. but simply flipping the cpu around as well as the "hat" part and it went flawlessly.

i used electric tape at the edges to make the force disperese a bit better on the unit. as well as around the CPU to hold it in place since it was not resting all the way into the hole.

the operation to pop the lid was very fast. took alot longer time to clean the PCB and lid.

I really think the tool does not need to be 100% formed to just one type of cpu and witha bit more hole in the bottom/inside it can fit a broad variety of CPU units.

i used electric tape at the edges to make the force disperese a bit better on the unit. as well as around the CPU to hold it in place since it was not resting all the way into the hole.

the operation to pop the lid was very fast. took alot longer time to clean the PCB and lid.

I really think the tool does not need to be 100% formed to just one type of cpu and witha bit more hole in the bottom/inside it can fit a broad variety of CPU units.

I really think the tool does not need to be 100% formed to just one type of cpu and witha bit more hole in the bottom/inside it can fit a broad variety of CPU units.

If all printer would have the same quality my printers have i would agree you 100%

But there are alot of different printers with different quality, and even printing different layerheight (from 0.05 up to 0,3mm layer height).

And i want to ensure that it will work least for most printers and not to crash the CPU`s

If i would make a tool for all there may be a higher chance that some people may fail with the tool which would not be good for reputation.

So thats why i go the "save" way with the tool and optimize it for each CPU typ.

Last edited by a moderator:

D4rkn3ss

2[H]4U

- Joined

- Jun 30, 2010

- Messages

- 2,619

haha nice

I though it was fairly well established that the TIM used is just fine, it's the separation between the top of the die and the underside of the IHS that is the issue. Which is why relidding is so dependant of proper seating and application of pressure (and why convex heatsink bases perform better than perfectly flat ones).which of course allows you to then remove the IHS and replace the somewhat anemic Intel Thermal Interface Material with something more robust.

For short term testing, or extreme overclocking, this is likely fine. But for long term operation, 'liquid metal' TIMs are not a good idea to use on bare dies. While the face of the die itself has a deposited metallic layer, the same is not true of the edges and underside of the die. The Gallium contained on those eutectic alloys is some nasty stuff and will quite happily infiltrate and redope Silicon (a few atoms of dopant will completely destroy a transistor). Particularly an issue with dies too small to be soldered (e.g. any LGA115x chip from Ivy Bridge onward), as they will lack the additional metallic layers of dies intended for soldering.We are using CoolLabs Liquid Ultra, and it has worked well giving us around a 20C temperature reduction in package temps using an Intel Core i7-7700K.

As an Amazon Associate, HardForum may earn from qualifying purchases.

Hi guys,

Can i use the kaby tool for delid i7 4790k haswell cpu ?

Cordially.

should also work for haswell, we delidded a G3258 successfully and the kaby tool only has two addition slots for the kaby tray, the rest is identical.

Chri

- Joined

- May 18, 1997

- Messages

- 55,634

Yes. Did a 4770K in the Hammer video.Hi guys,

Can i use the kaby tool for delid i7 4790k haswell cpu ?

Cordially.

- Joined

- May 18, 1997

- Messages

- 55,634

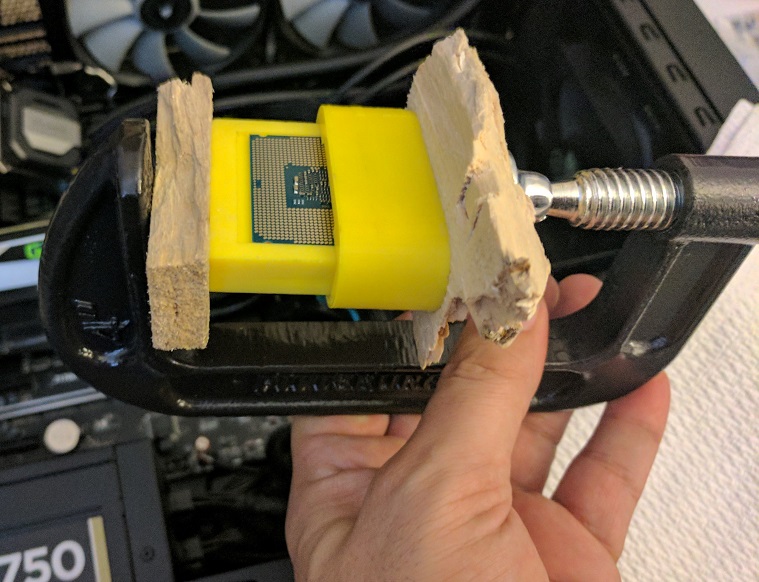

Rainy weekend, decided to get this done....

$3 c-clamp from Harbor freight and wood scraps. That Pop others report is real! but worked so nice!

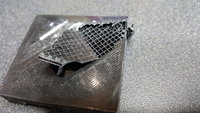

Cleaned and TIM applied

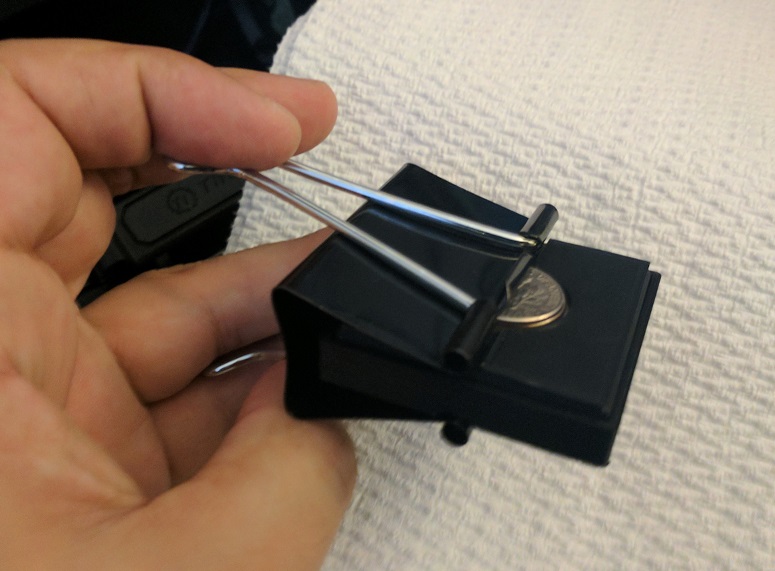

Used a binder clip as it seemed the perfect size, I did stick a couple of dimes on top of the lid because I wanted the pressure more so on the center of the lid than on the edges....

So now to wait till tonight and hope it posts!! Thanks Kyle and Chri!

$3 c-clamp from Harbor freight and wood scraps. That Pop others report is real! but worked so nice!

Cleaned and TIM applied

Used a binder clip as it seemed the perfect size, I did stick a couple of dimes on top of the lid because I wanted the pressure more so on the center of the lid than on the edges....

So now to wait till tonight and hope it posts!! Thanks Kyle and Chri!

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)