- Joined

- May 18, 1997

- Messages

- 55,598

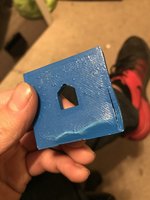

3D Print Your Own Intel Delid Tool for Skylake & Kaby Lake - A lot of us have come to find out recently that Intel once again skimped on the Thermal Interface Material inside these processors' Integrated Heat Spreaders. You can fix that issue however, and now there are some ways to do it safely. If you have a 3D printer, you can make the process a lot safer, and the tools needed much less expensive.

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)