Zarathustra[H]

Extremely [H]

- Joined

- Oct 29, 2000

- Messages

- 38,830

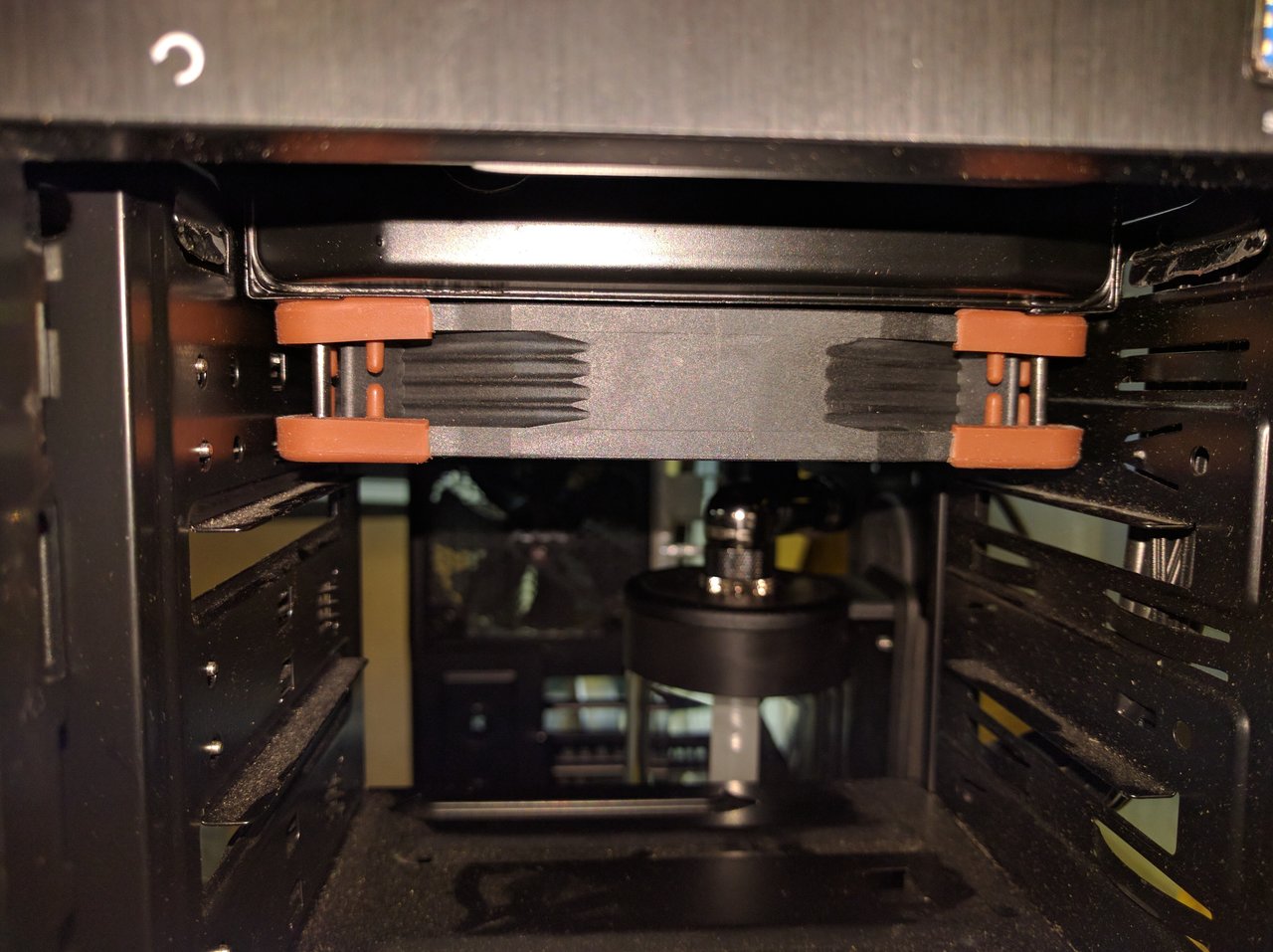

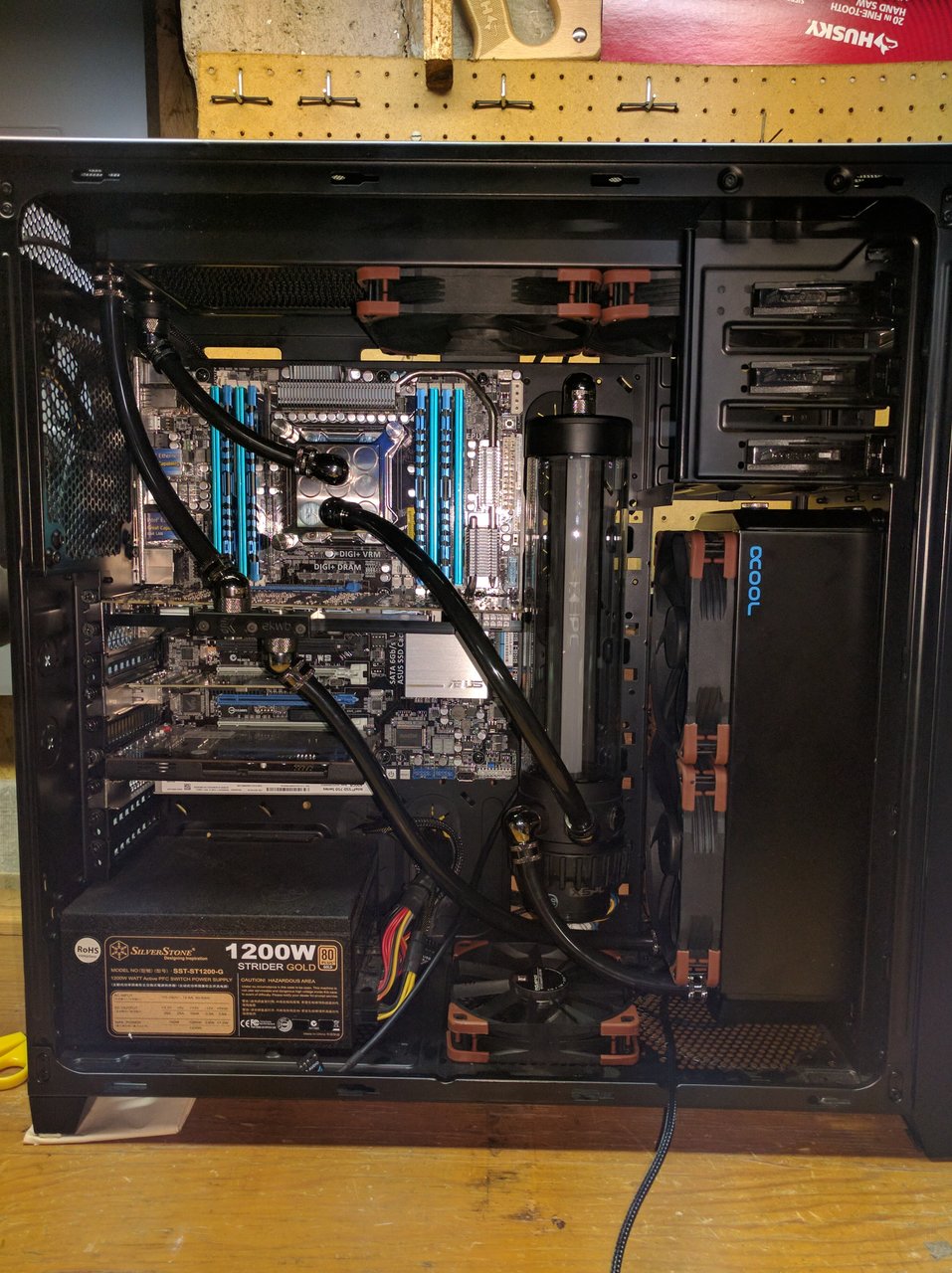

Hmm. This new unplanned tube routing is going to require some sort of bend coming out of the front radiator in order to reach the pump, but this XSPC 45 degree fitting is too short to get around the fan...

View attachment 6719

Nope, the routing just is not going to work with the radiator in this orientation. I'm going to try to figure out a way to mount it upside down. It's probably drill-n-pray time...

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)