**Also posted over at Overclock.net- [Build Log] Fat guy in a little coat; water cooled Node 304 - Page 5

This is my first real attempt at having a build log. Usually I would just use the components as is when I build them. I'm definitely a noob when it comes to this type of modding. I did post other pics over at OC.net but thought I would share here.

OBJECTIVE;

Water cool and clean up cabling.

SPECS;

CPU; Intel i7-4770K

RAM; G-Skill Ripjaws DDR3 1600 2x4GB

HDD; Western Digital 500GB RE3

GPU; EVGA GTX 660 SC

PSU; Corsair CX430W PSU

CASE; Fractal Node 304

LOOP SPECS;

RAD; Coolgate 280 (2x140mm)

CPU; XSPC Raystorm

GPU; EK Full cover

PMP; MCP355 w/ Koolance top

RES; Bitspower 80ml

ADDONS;

30x Bitspower Super Tight Weave 1/16 Black

30x Bitspower Super Tight Weave 1/16 White

20x Bitspower Super Tight Weave 1/4 Black

20x Bitspower Super Tight Weave 1/4 White

10x Bitspower Super Tight Weave 1/8 Black

3x Red and White LEDs

1x XSPC LCD Temperature Sensor V2 w/ sensor plug

2x XSPC LCD Temperature Sensor w/ sensor prob

1x Bitspower G1/4" Matt Black Q-Rotary Adapter

2x Swiftech 15mm Lok-Seal Male/Female extension

3x Swiftech 3/8" Barb (2pack)

5x Swiftech 45° Swivel Elbow

4x Swiftech 90° Swivel Elbow (will not be used due to leaking)

12x Primoflex Advanced LRT tube White 3/8 x 5/8

12x PrimoChill Anti-Kink Coils 5/8" Red

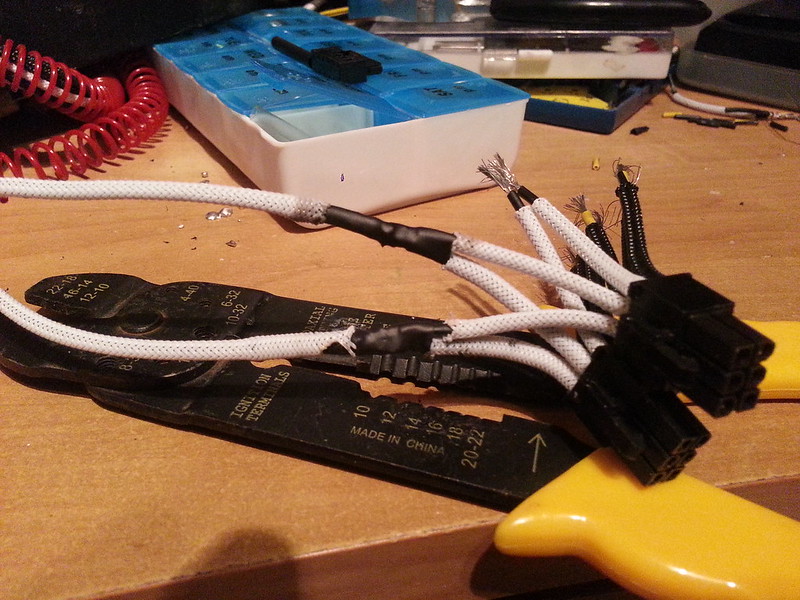

Pre-build... We're going to have to do something about that cabling!

Pre-build, HDD cage hitting GFX card

H80i

No disassemble!

Pure nakedness

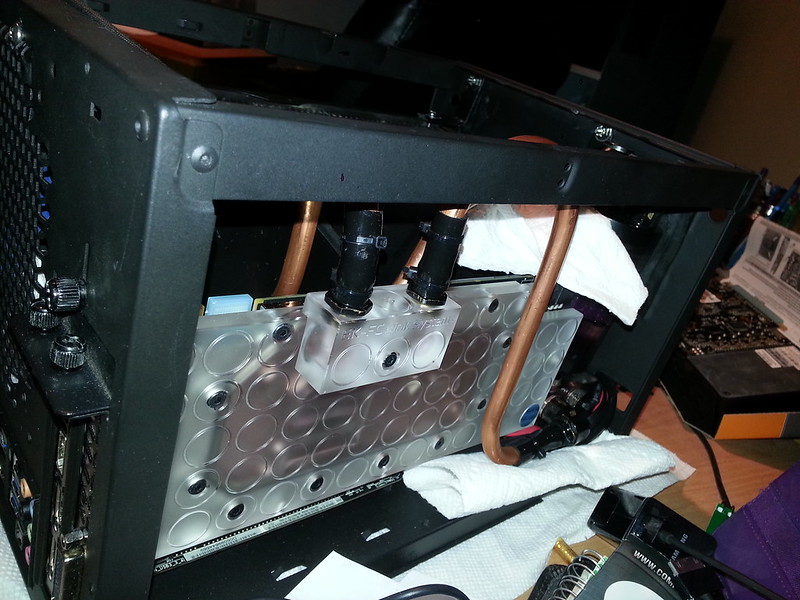

GFX card block addition

GFX card block installed

CPU block installed

Looks like clearance is very slim or it's hitting the cpu locking bracket

Let's remove that...

What the...

HEY!!! Easiest delid FTW!! (bought used, did not realize it had been delided)

Cleaning up WB for even seat on CPU die (unfortunately, I did not get finished shot)

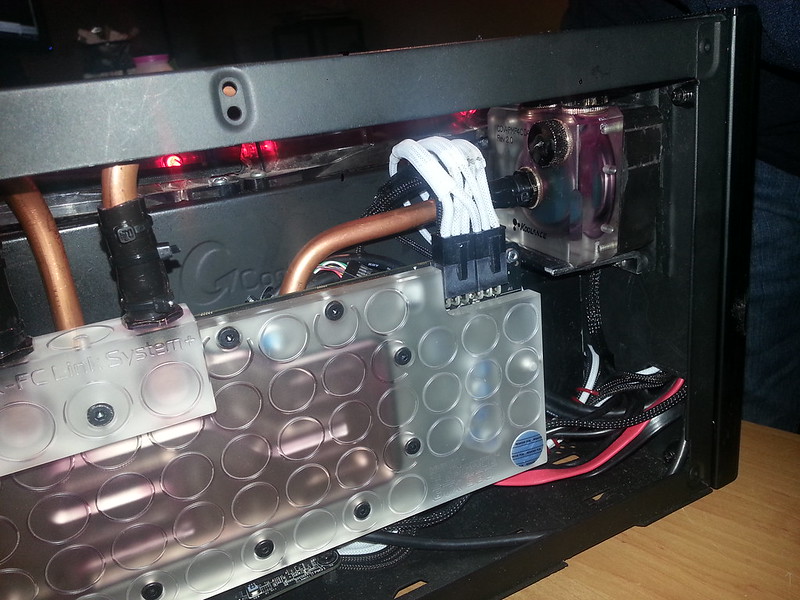

No more clearance issues (wires are for temp prob)

Running plumbing and checking tubing clearances (I changed out 90deg for 45deg)

More tubing running and checking of clearances

Clearance check from the top

Leak testing and air removal (90deg already removed)

Testing temp lcd's (2 shown; 3 in total)

More to come

This is my first real attempt at having a build log. Usually I would just use the components as is when I build them. I'm definitely a noob when it comes to this type of modding. I did post other pics over at OC.net but thought I would share here.

OBJECTIVE;

Water cool and clean up cabling.

SPECS;

CPU; Intel i7-4770K

RAM; G-Skill Ripjaws DDR3 1600 2x4GB

HDD; Western Digital 500GB RE3

GPU; EVGA GTX 660 SC

PSU; Corsair CX430W PSU

CASE; Fractal Node 304

LOOP SPECS;

RAD; Coolgate 280 (2x140mm)

CPU; XSPC Raystorm

GPU; EK Full cover

PMP; MCP355 w/ Koolance top

RES; Bitspower 80ml

ADDONS;

30x Bitspower Super Tight Weave 1/16 Black

30x Bitspower Super Tight Weave 1/16 White

20x Bitspower Super Tight Weave 1/4 Black

20x Bitspower Super Tight Weave 1/4 White

10x Bitspower Super Tight Weave 1/8 Black

3x Red and White LEDs

1x XSPC LCD Temperature Sensor V2 w/ sensor plug

2x XSPC LCD Temperature Sensor w/ sensor prob

1x Bitspower G1/4" Matt Black Q-Rotary Adapter

2x Swiftech 15mm Lok-Seal Male/Female extension

3x Swiftech 3/8" Barb (2pack)

5x Swiftech 45° Swivel Elbow

4x Swiftech 90° Swivel Elbow (will not be used due to leaking)

12x Primoflex Advanced LRT tube White 3/8 x 5/8

12x PrimoChill Anti-Kink Coils 5/8" Red

Pre-build... We're going to have to do something about that cabling!

Pre-build, HDD cage hitting GFX card

H80i

No disassemble!

Pure nakedness

GFX card block addition

GFX card block installed

CPU block installed

Looks like clearance is very slim or it's hitting the cpu locking bracket

Let's remove that...

What the...

HEY!!! Easiest delid FTW!! (bought used, did not realize it had been delided)

Cleaning up WB for even seat on CPU die (unfortunately, I did not get finished shot)

No more clearance issues (wires are for temp prob)

Running plumbing and checking tubing clearances (I changed out 90deg for 45deg)

More tubing running and checking of clearances

Clearance check from the top

Leak testing and air removal (90deg already removed)

Testing temp lcd's (2 shown; 3 in total)

More to come

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)

20160217_202855

20160217_202855 20160217_215008

20160217_215008 20160217_215220

20160217_215220 20160217_202906

20160217_202906 20160218_190350

20160218_190350 20160218_190400

20160218_190400