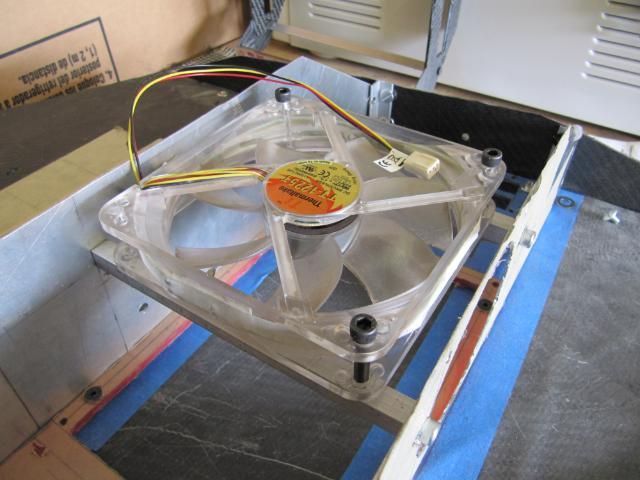

Hello. Its been a moment due to the Easter holiday and waiting on welding brackets. Than I thought I lost my camera until I found it:wallbash::clap:. Update time

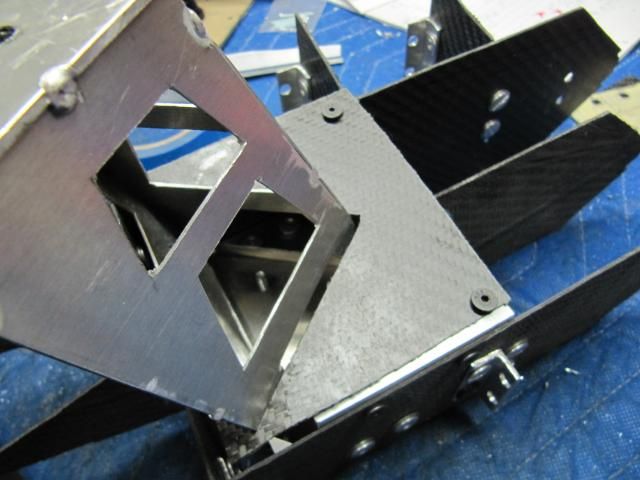

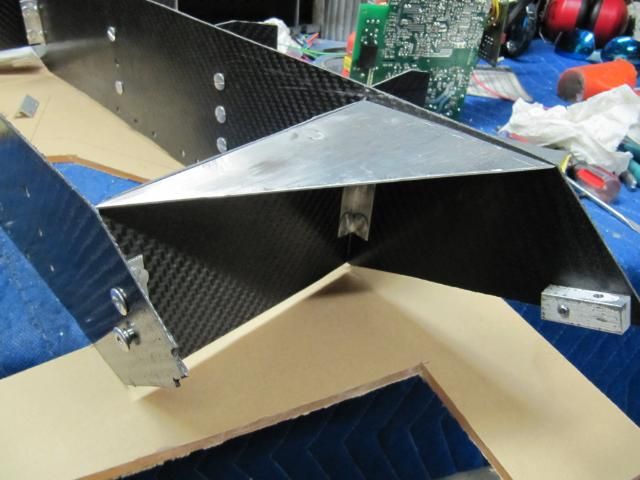

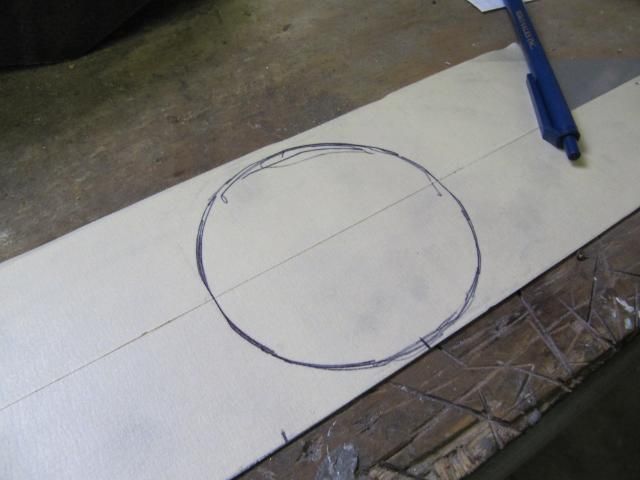

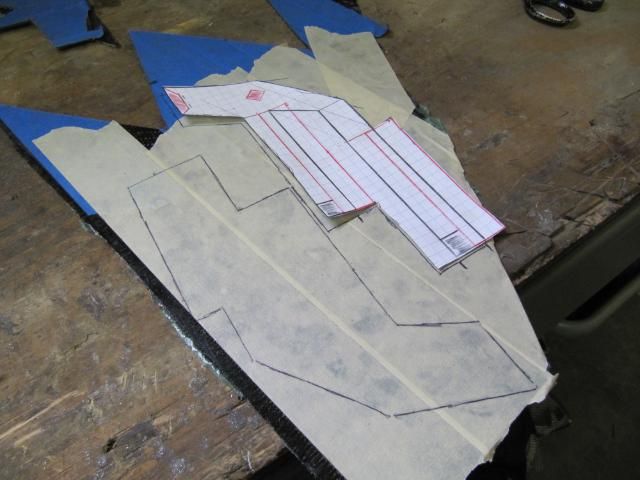

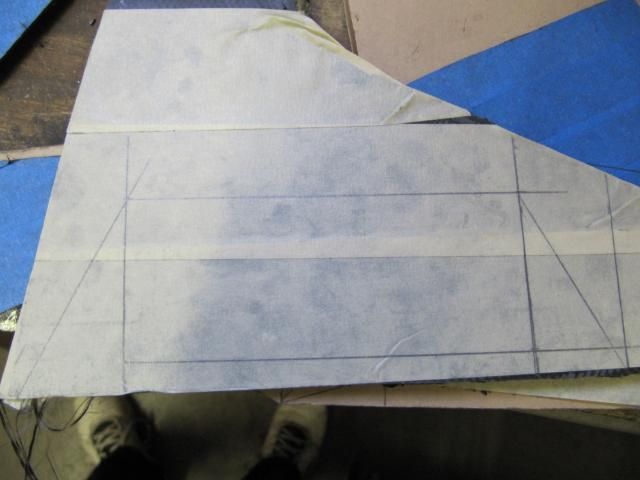

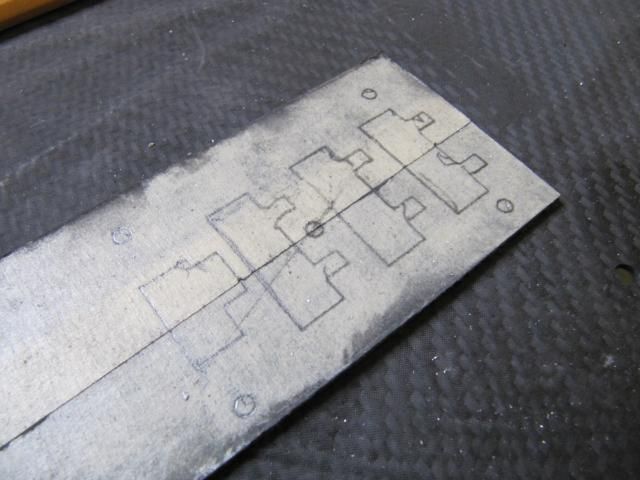

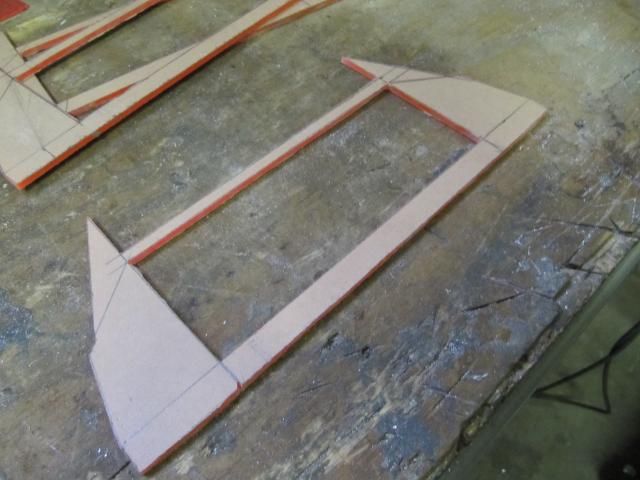

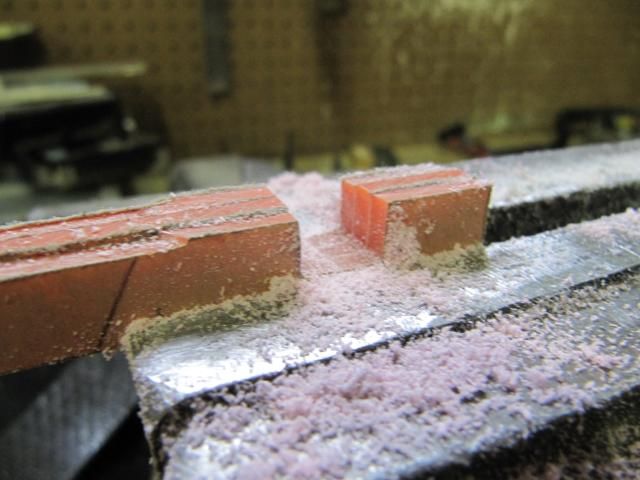

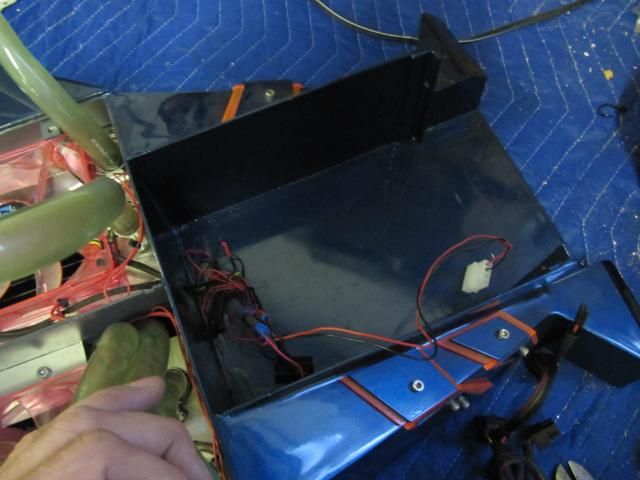

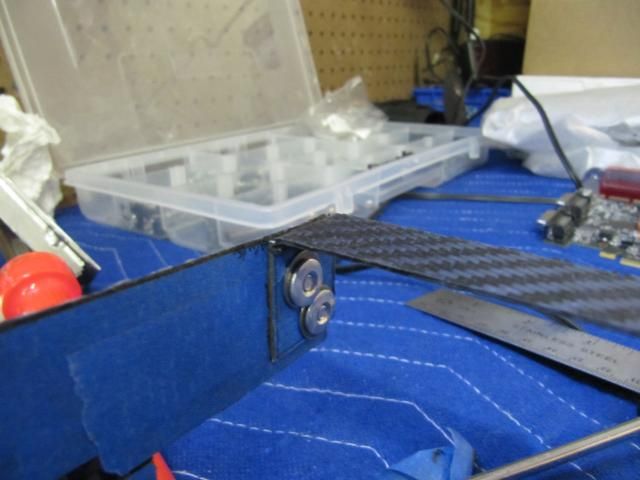

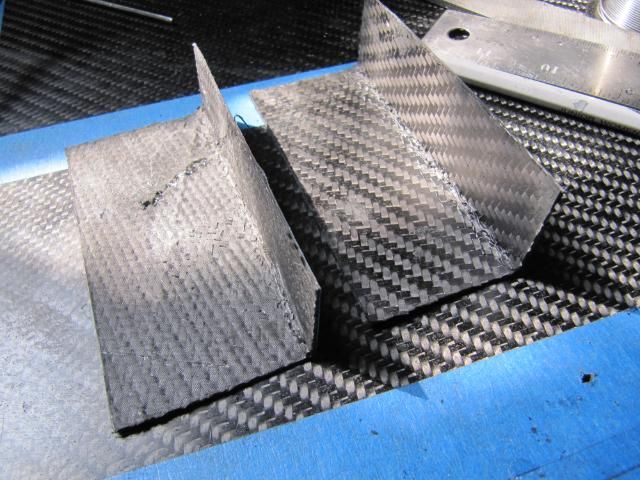

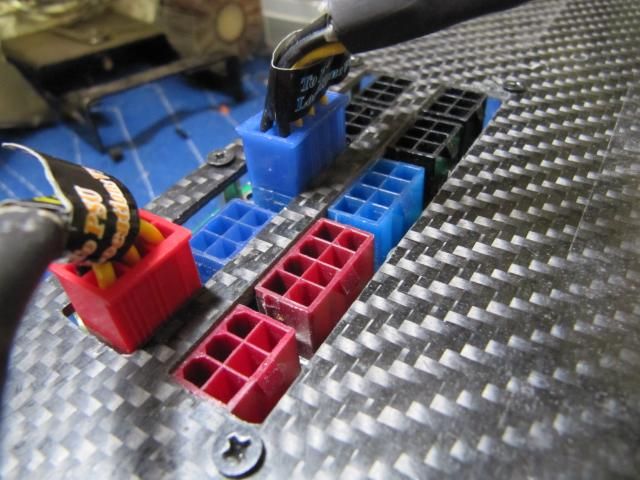

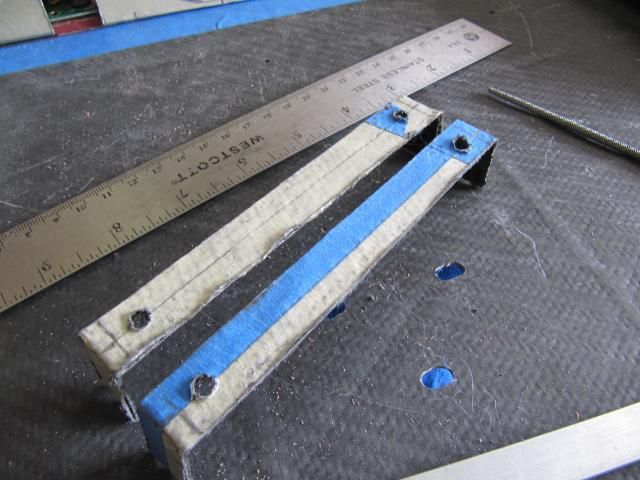

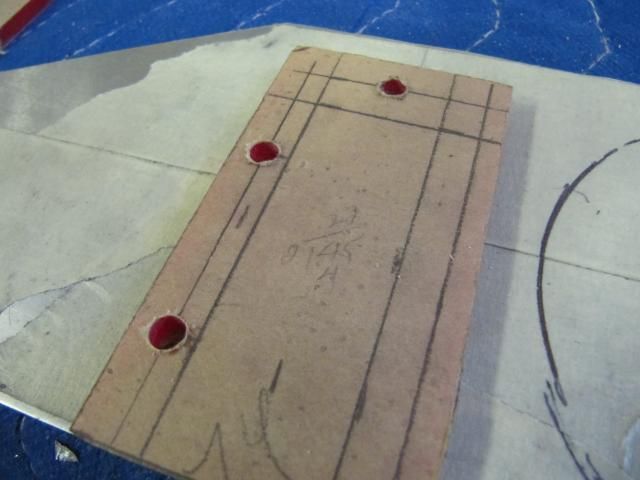

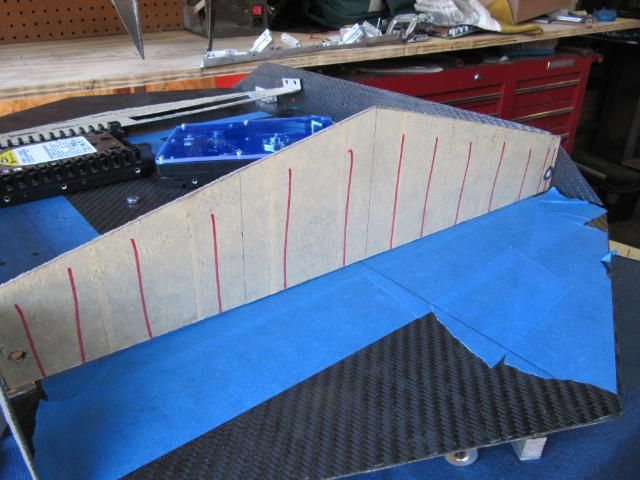

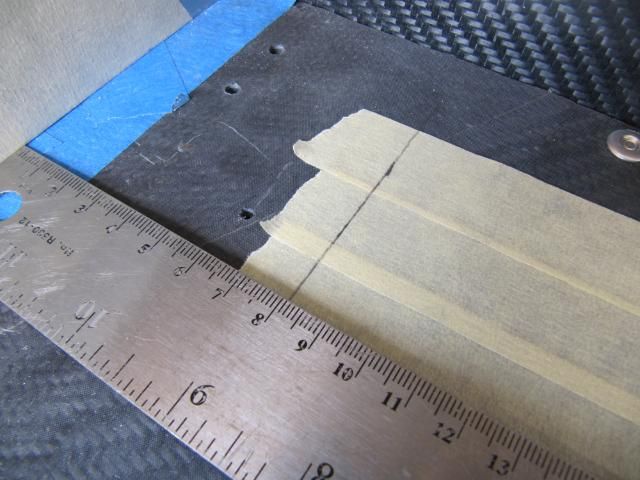

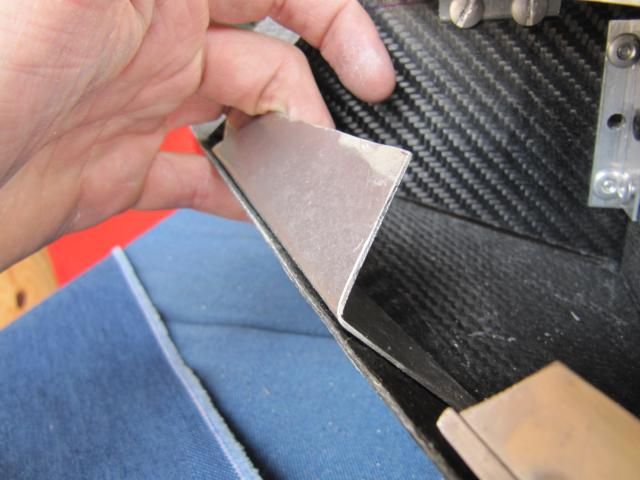

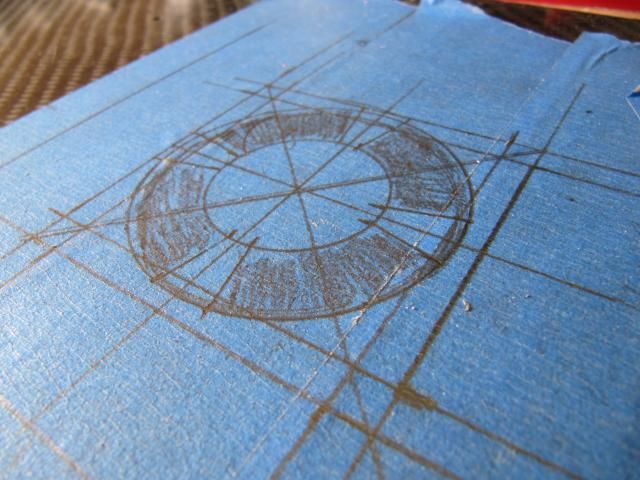

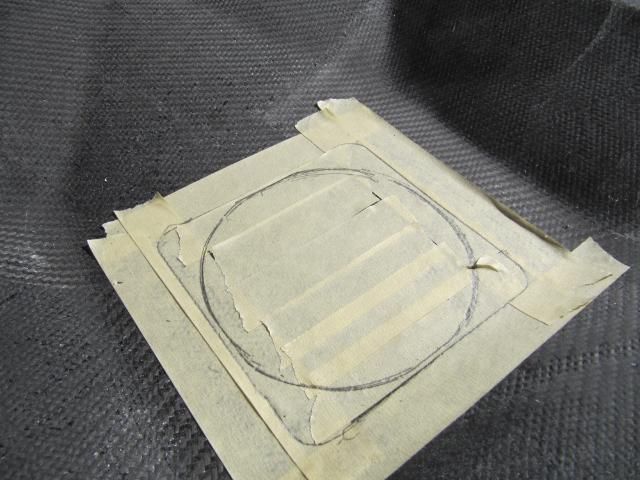

These pieces will be for the intake inlet. They will mount to the frame.

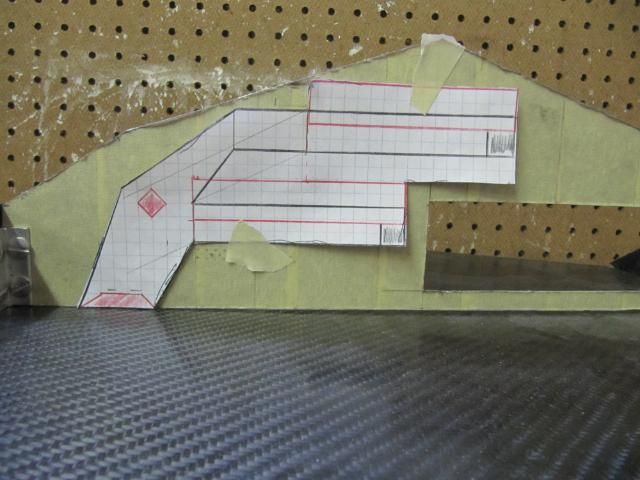

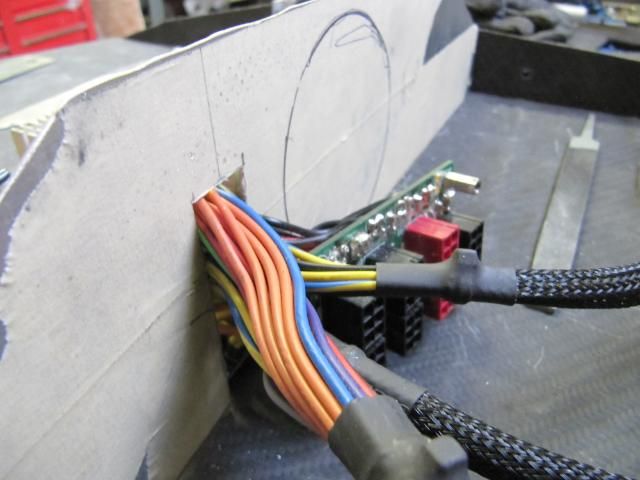

There locations

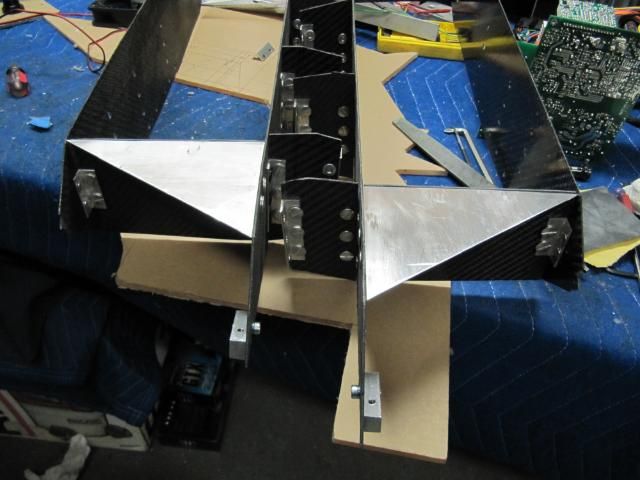

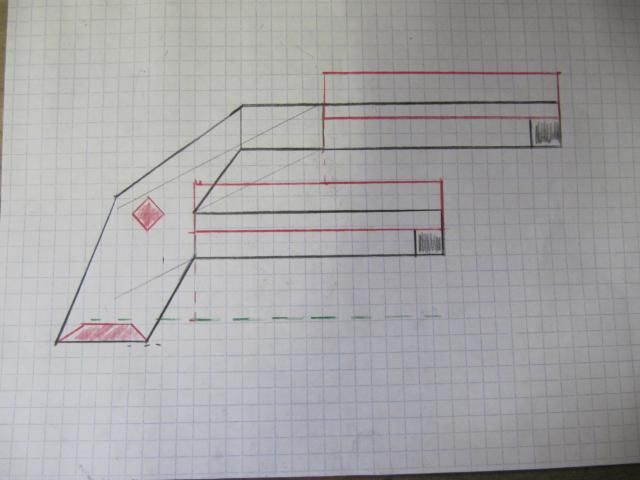

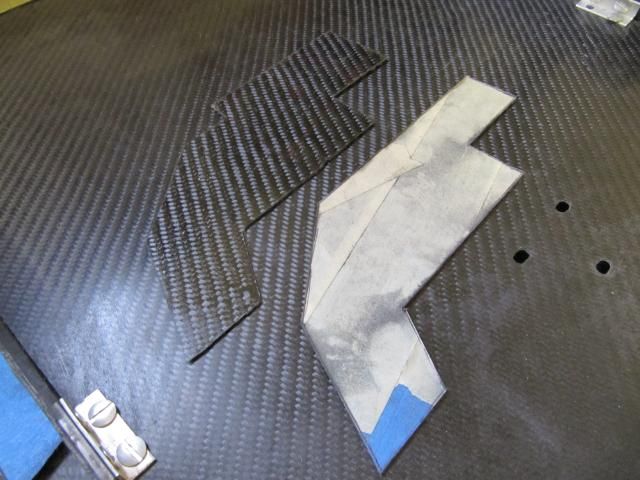

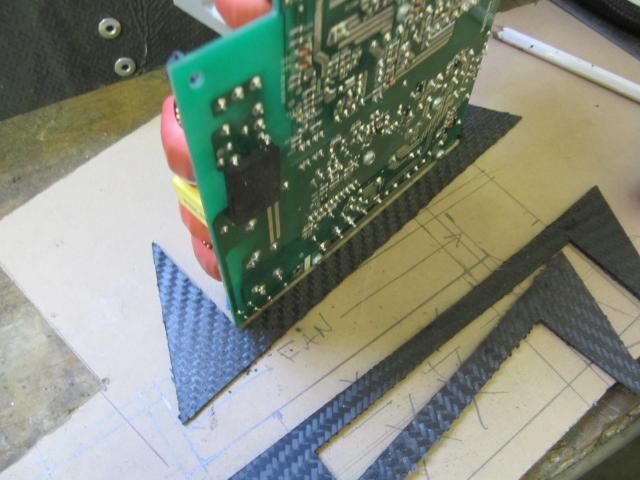

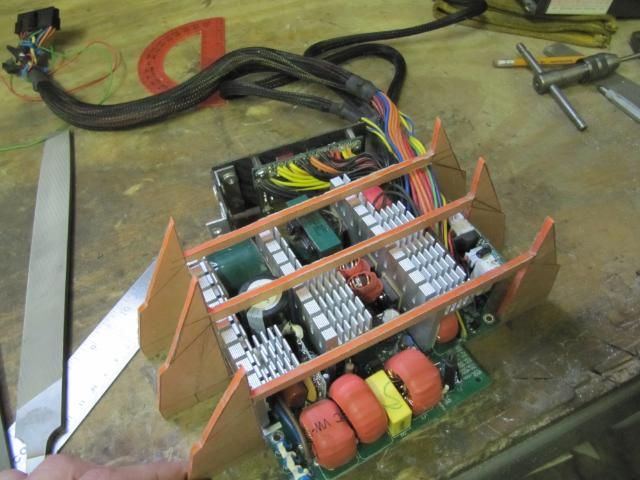

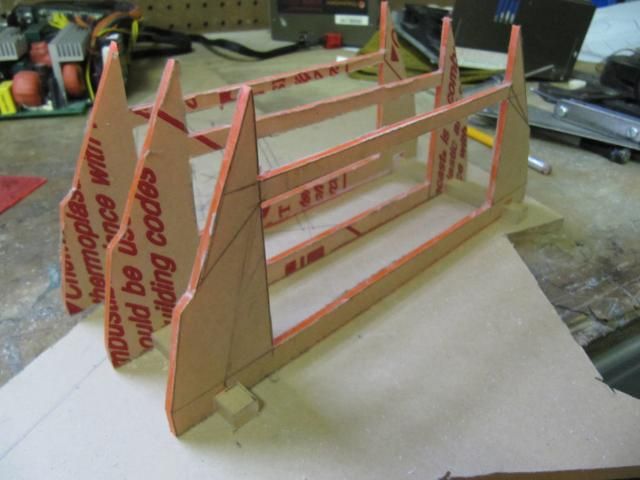

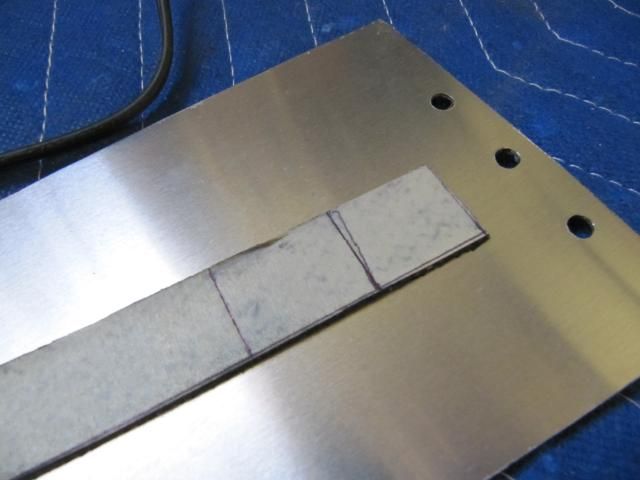

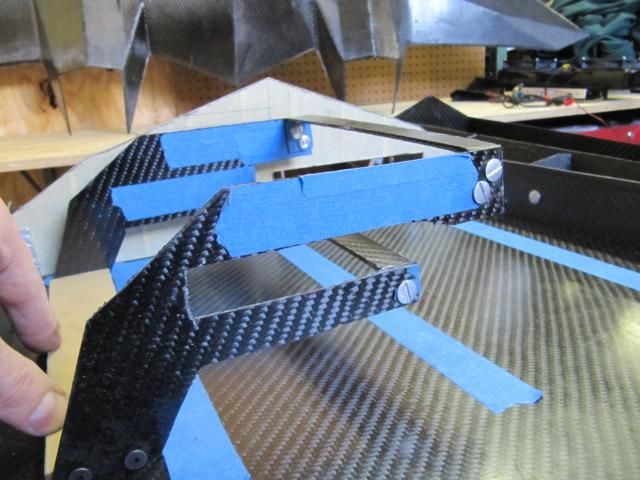

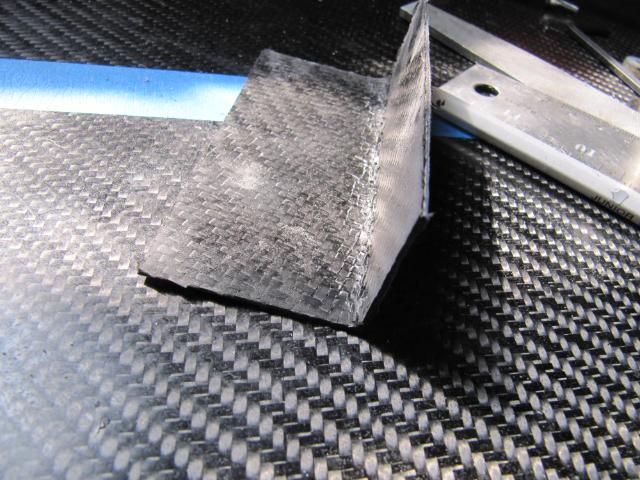

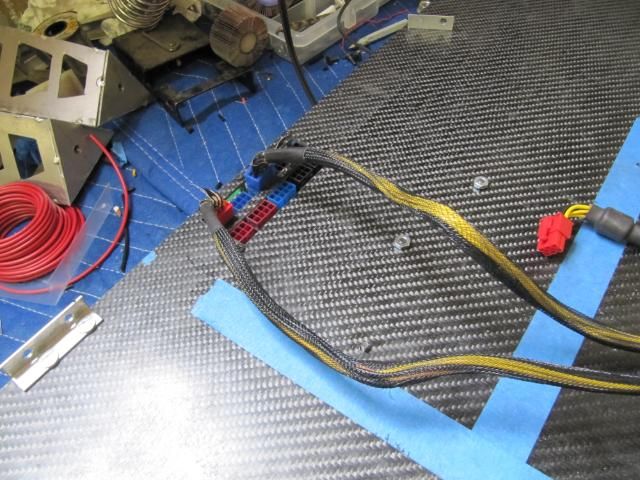

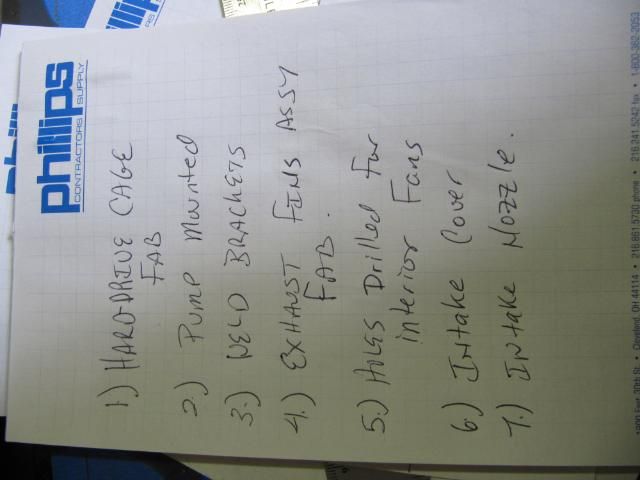

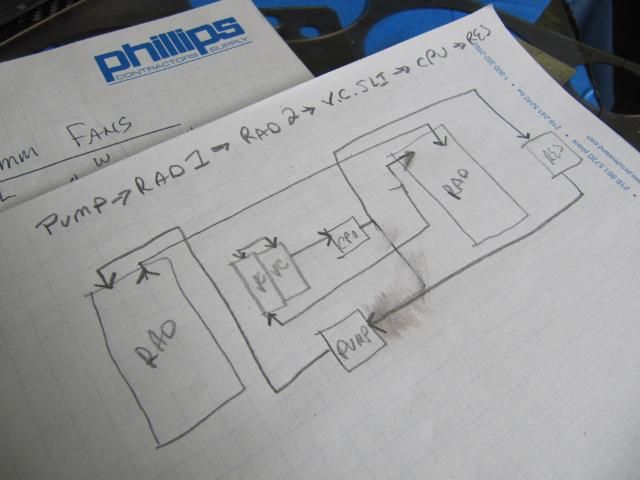

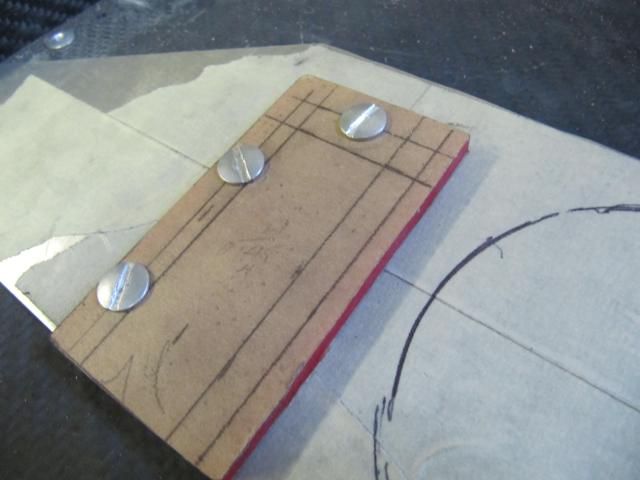

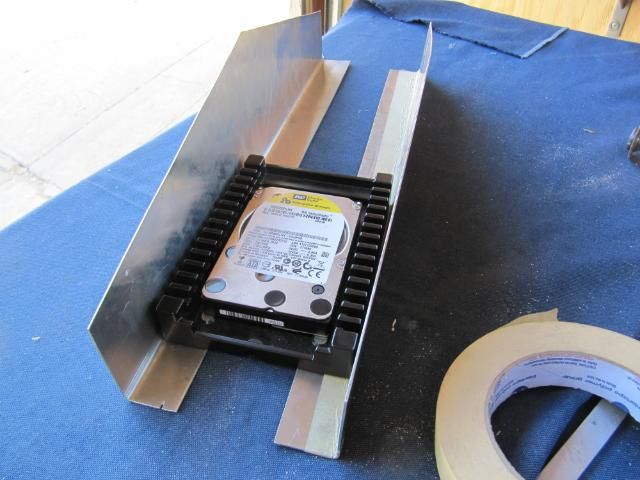

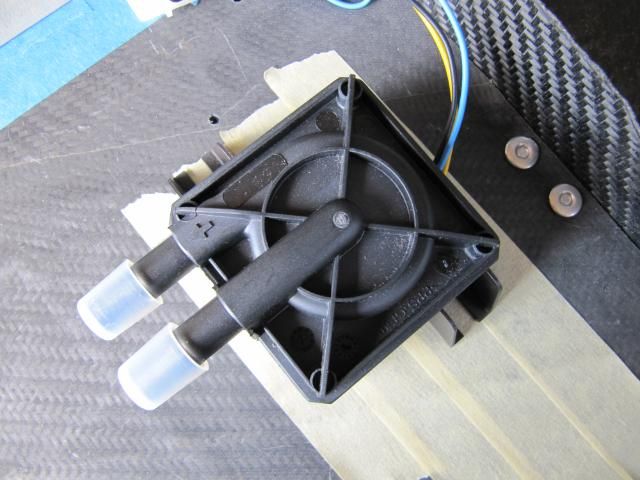

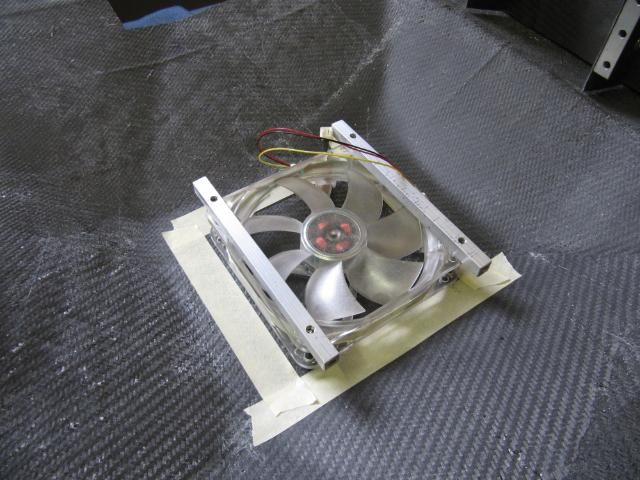

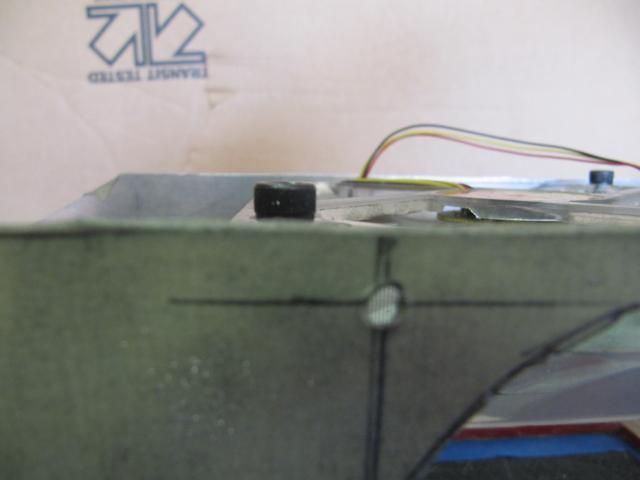

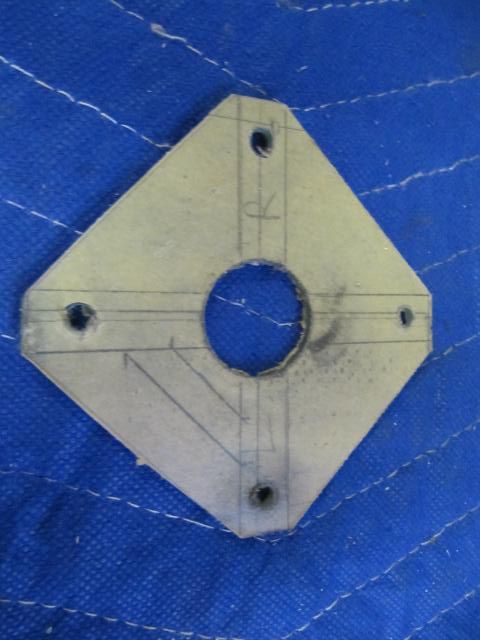

The bracketing that I decided to roll with is simple and lightweight.

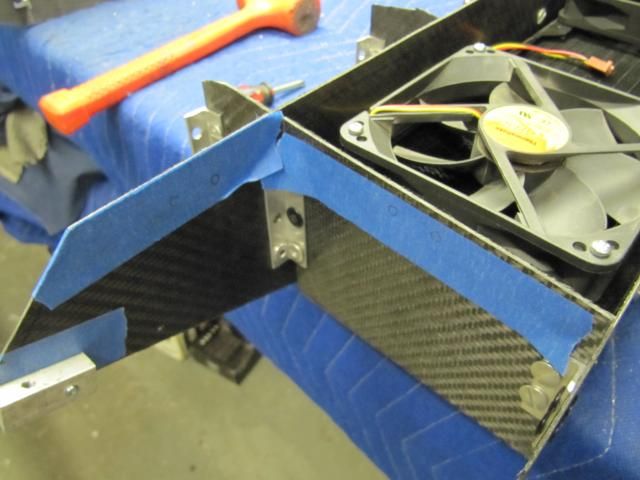

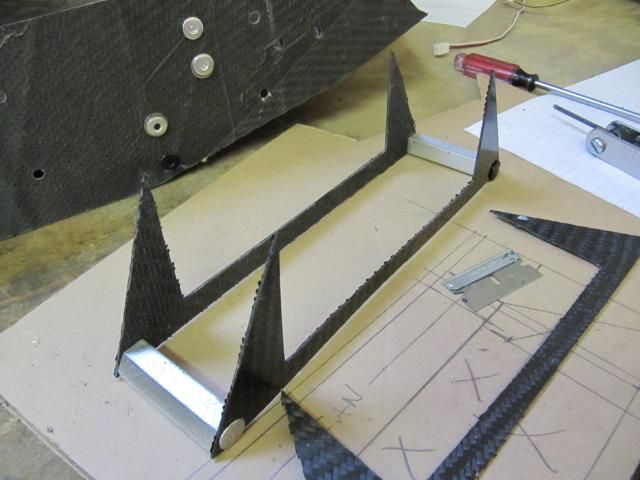

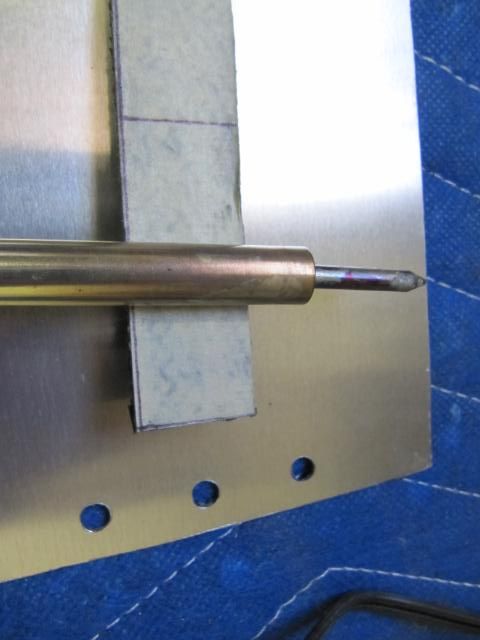

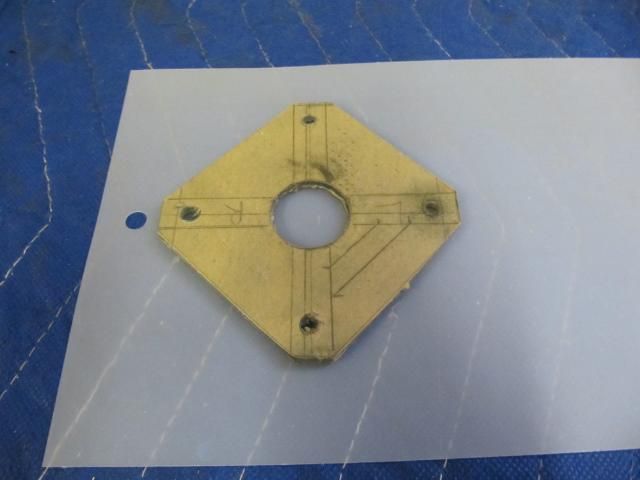

Moving onto finishing the wing-tip brackets

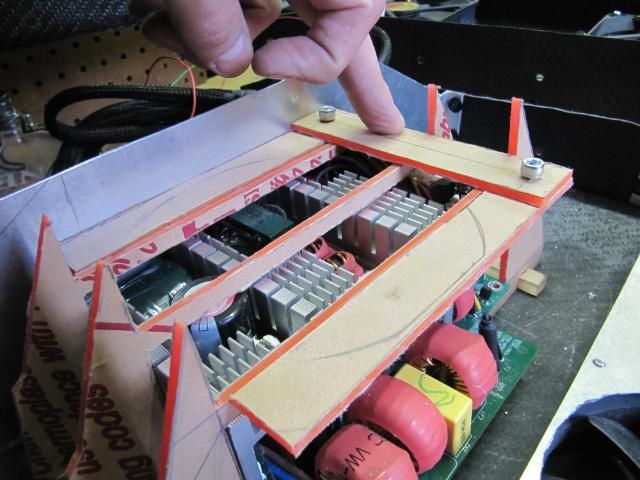

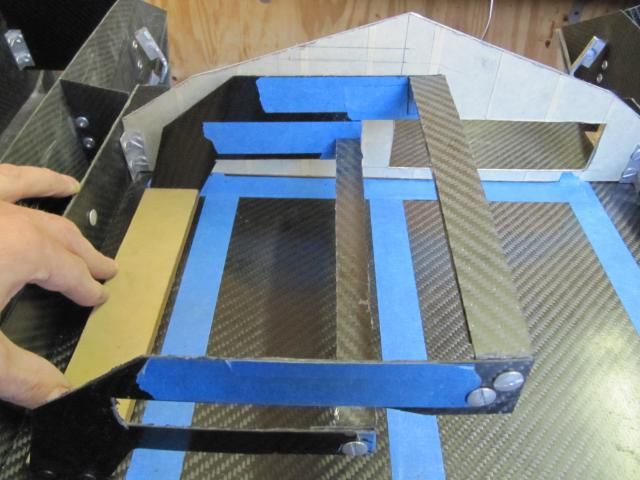

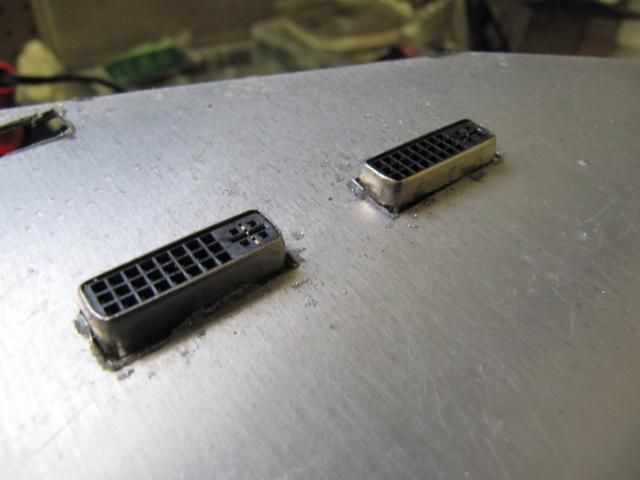

So I had to wait the weekend out before I could due get these mounted properly. They need to be welded together. Trying to mount each piece than weld would most likely result in some major misalignment of the covers.

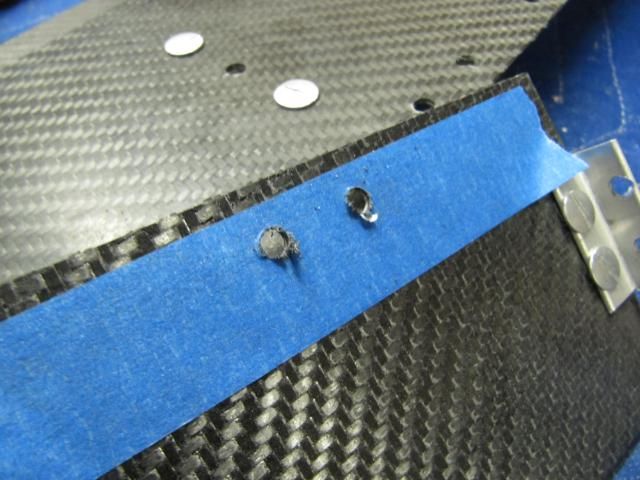

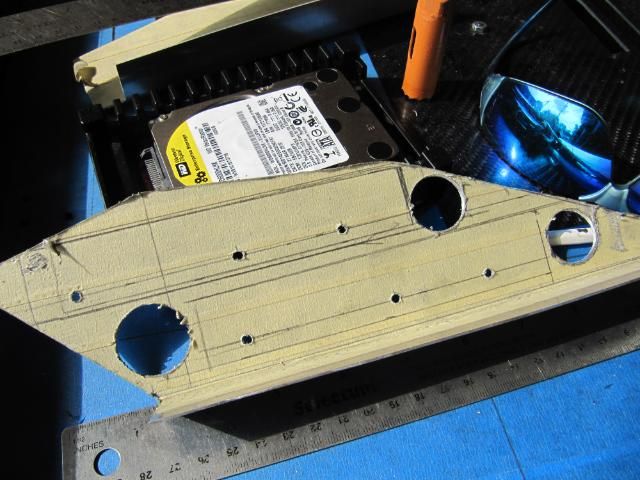

Drilled some holes

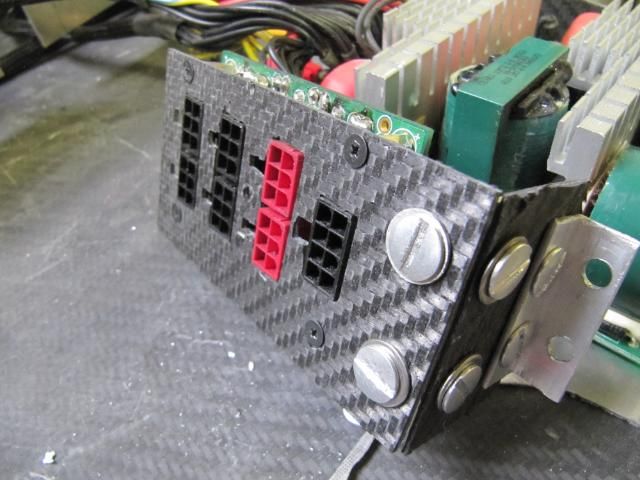

Mounted On.

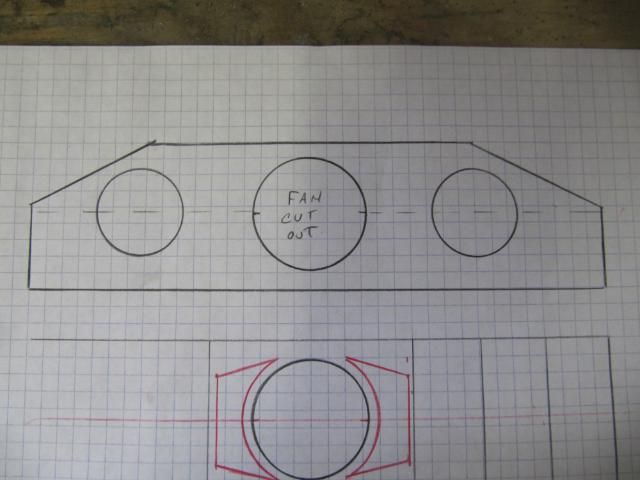

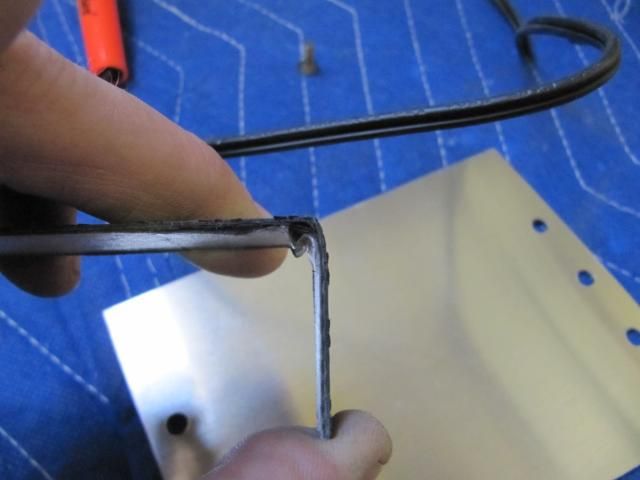

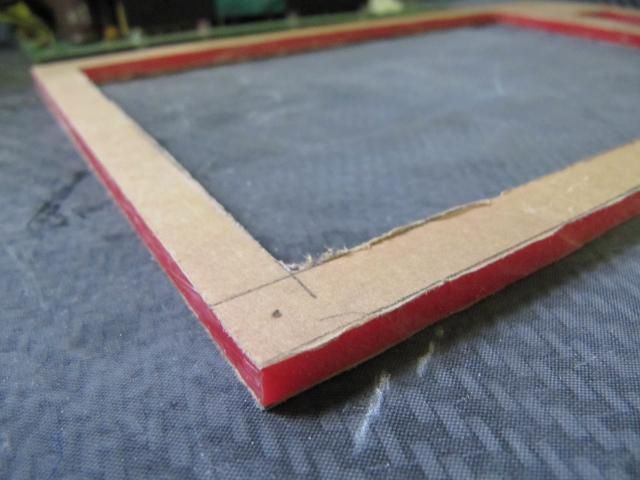

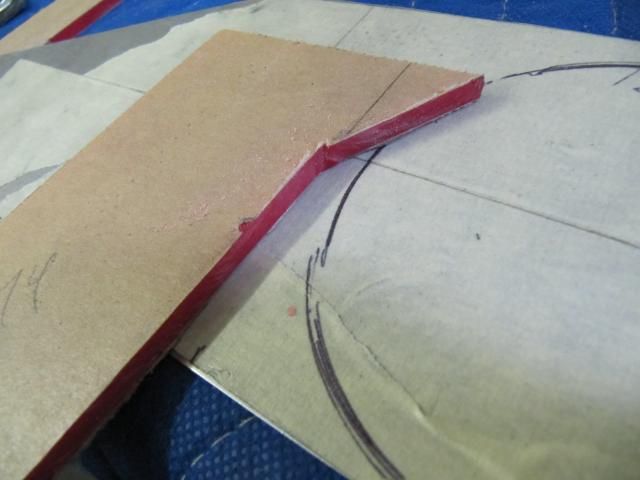

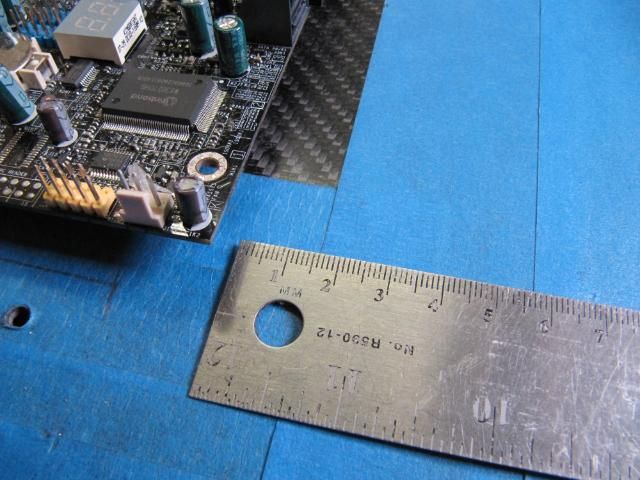

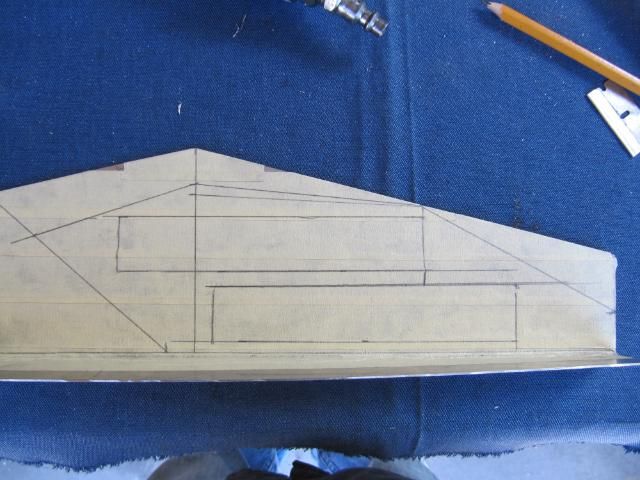

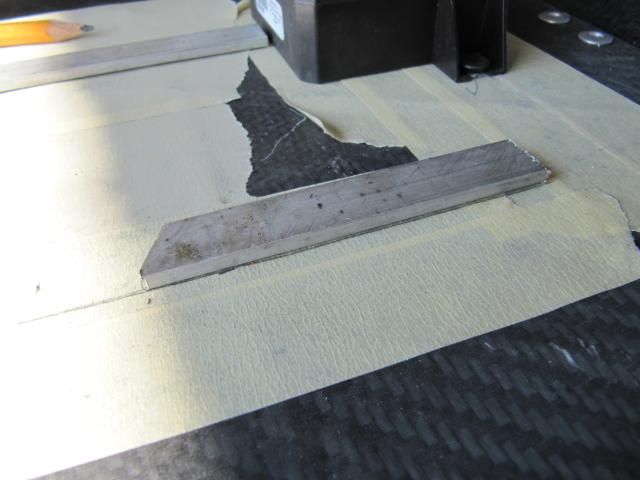

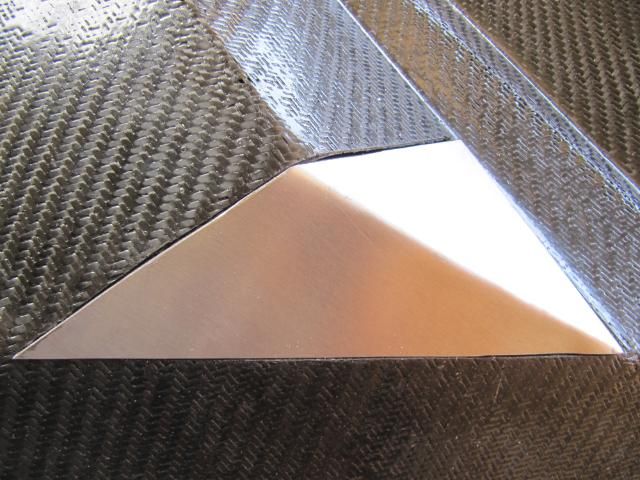

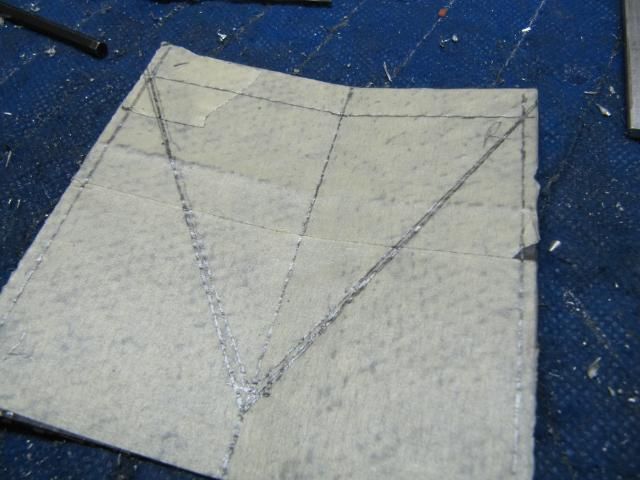

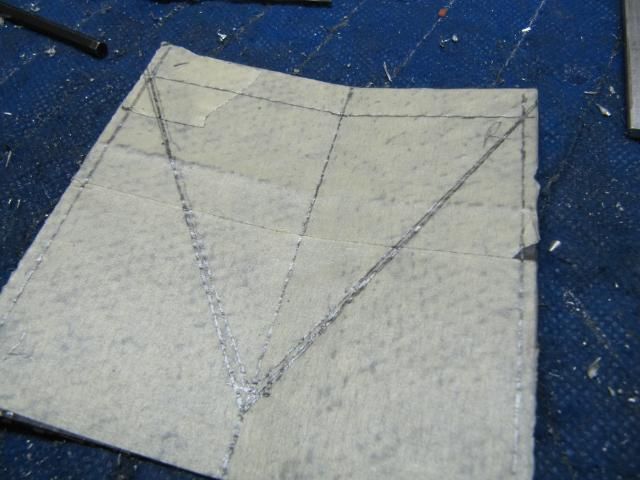

I went back today and started to finishing working on the covers for the case feet.

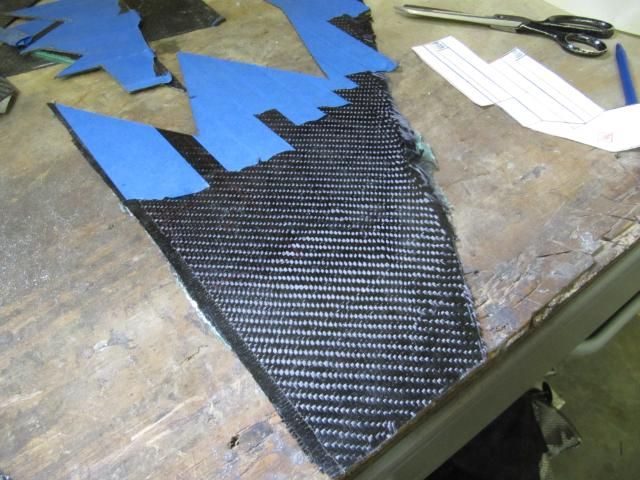

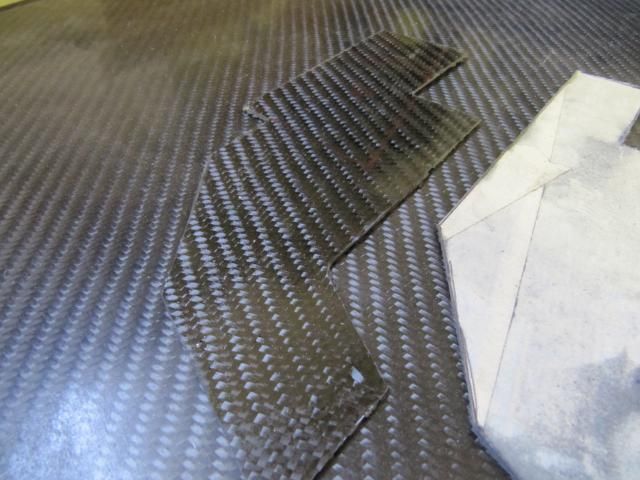

Both feet got cut out. Pics for only the right side foot here. I'll be updating with you more.

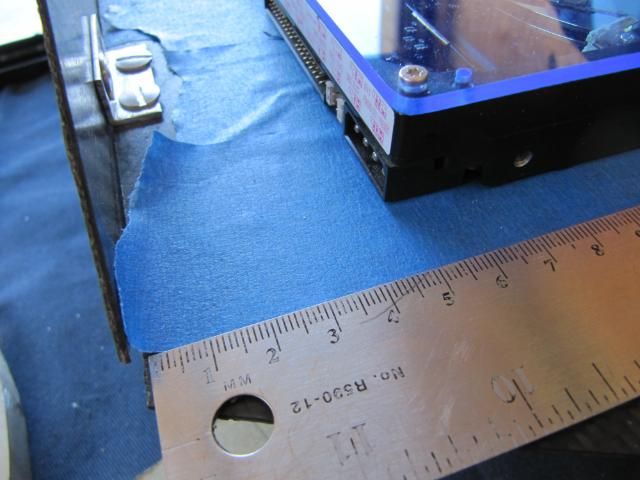

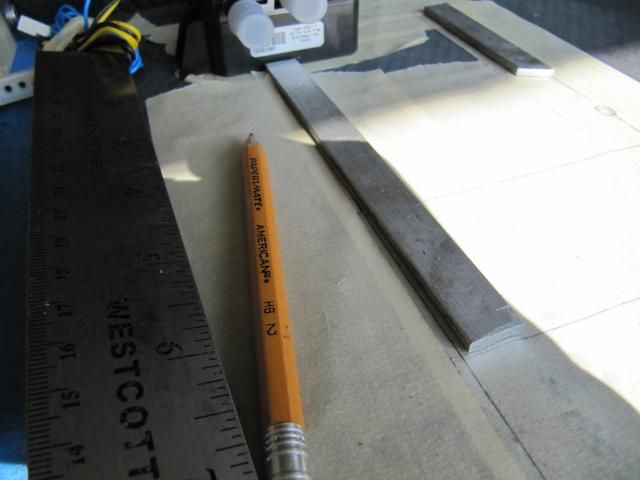

Now I have to fabricate some brackets to hold these covers to the frame. That is tomorrow.

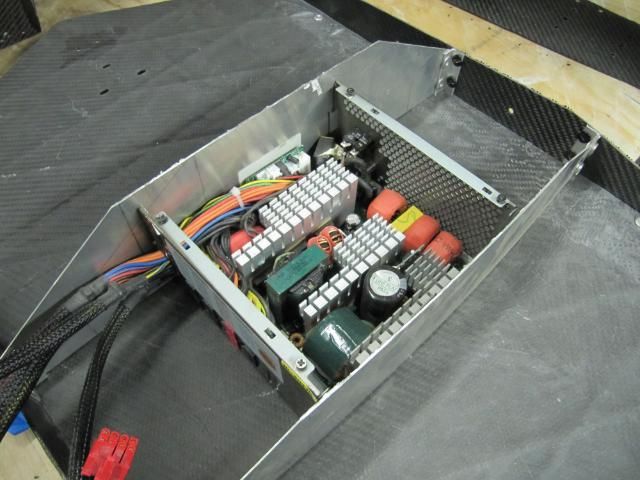

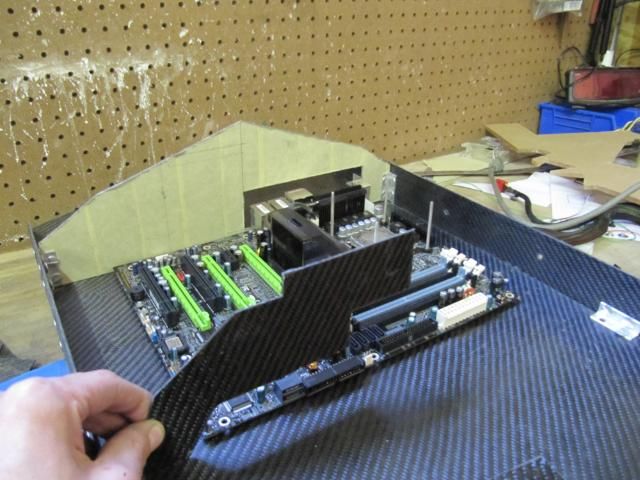

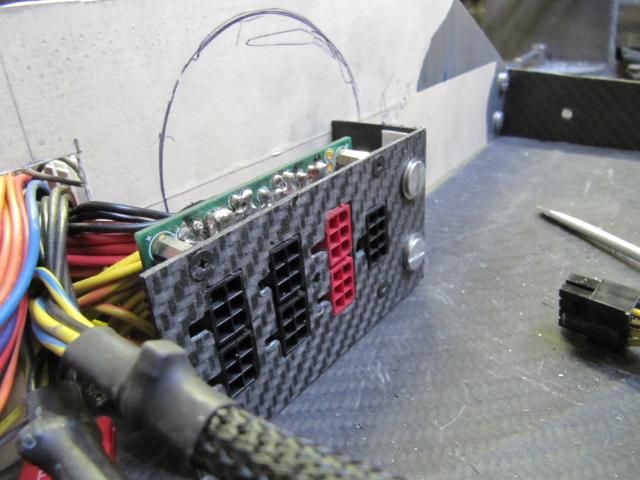

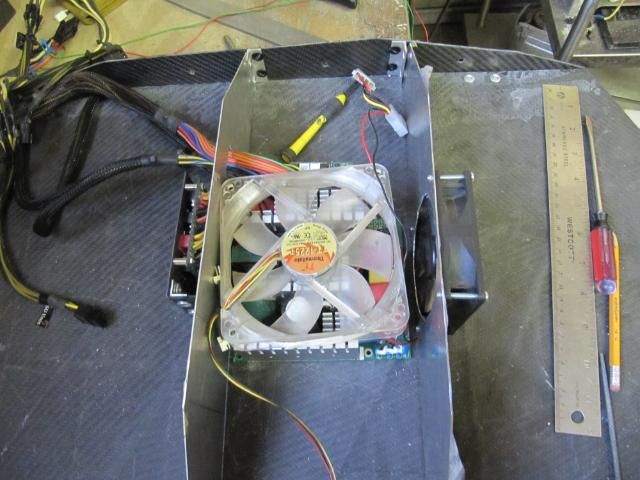

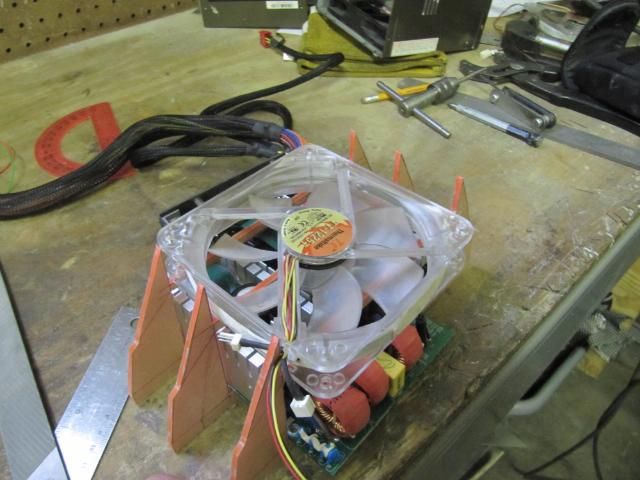

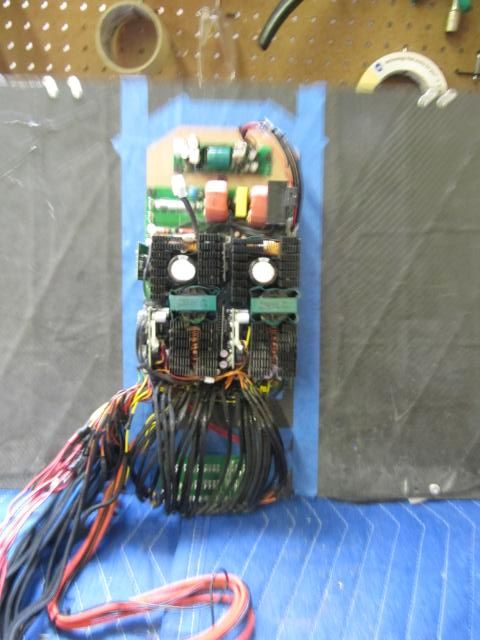

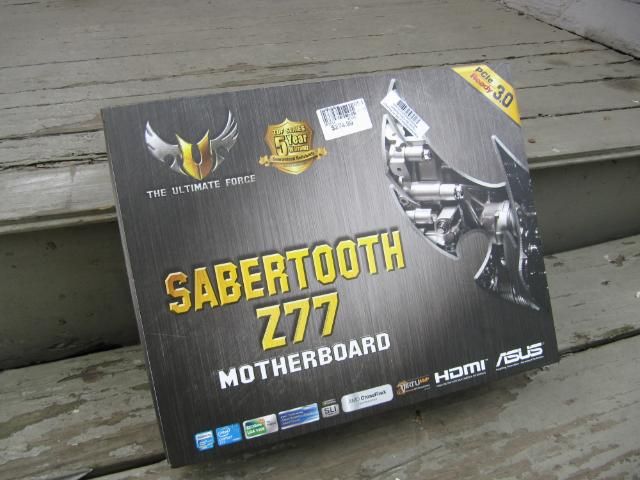

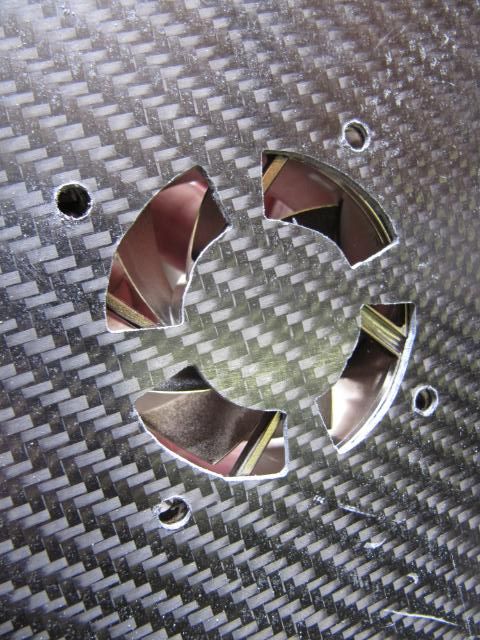

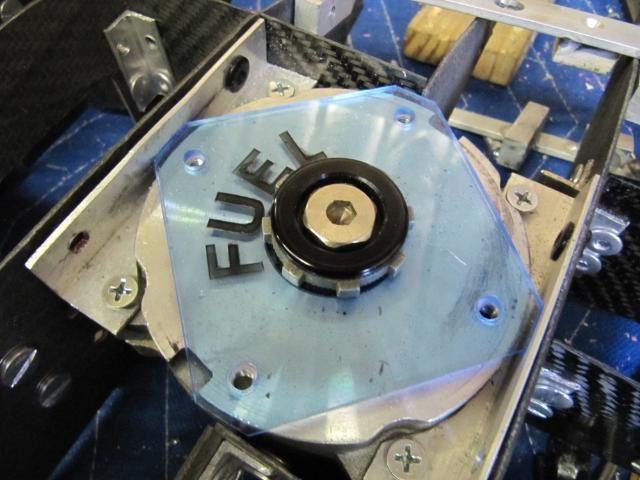

Sneak Peek

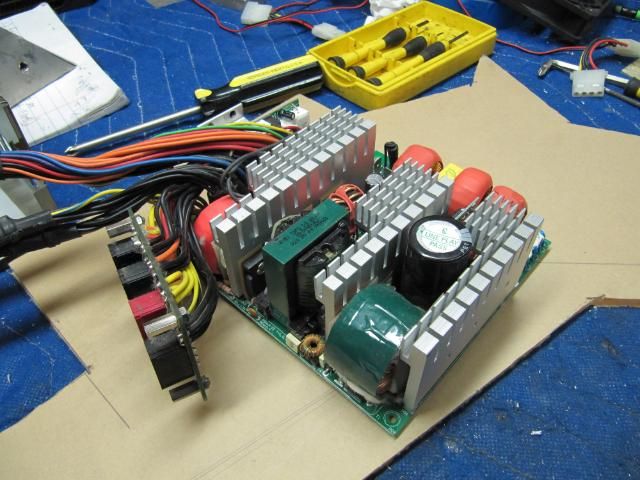

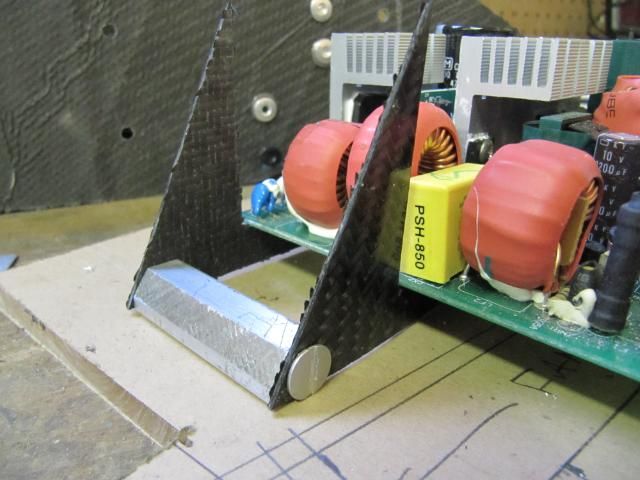

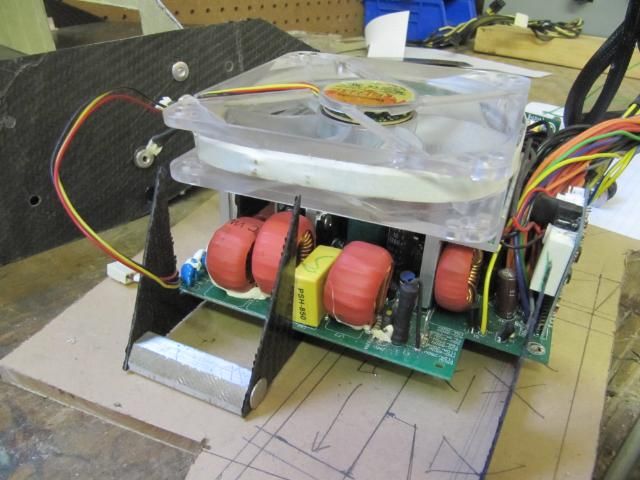

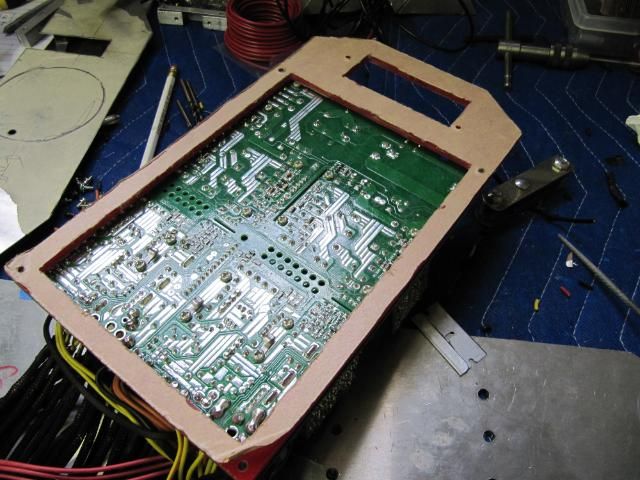

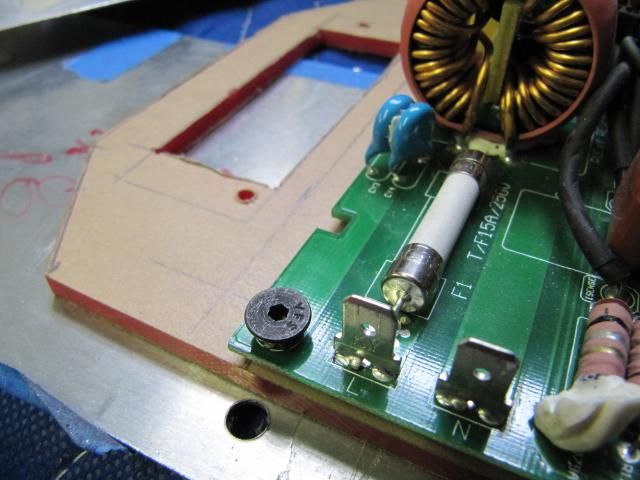

For all the people who DON'T believe me, when I say I'm mounting SSR-X on my truck

Stay Tuned

These pieces will be for the intake inlet. They will mount to the frame.

There locations

The bracketing that I decided to roll with is simple and lightweight.

Moving onto finishing the wing-tip brackets

So I had to wait the weekend out before I could due get these mounted properly. They need to be welded together. Trying to mount each piece than weld would most likely result in some major misalignment of the covers.

Drilled some holes

Mounted On.

I went back today and started to finishing working on the covers for the case feet.

Both feet got cut out. Pics for only the right side foot here. I'll be updating with you more.

Now I have to fabricate some brackets to hold these covers to the frame. That is tomorrow.

Sneak Peek

For all the people who DON'T believe me, when I say I'm mounting SSR-X on my truck

Stay Tuned

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)