A couple of months back my four year old 80gig sata which housed the entirety of mp3 collection died. Of course, I didn't have a backup. For nigh on a year, sorting out a NAS/WHS box was on the to-do list but I never got round to it before it was too late which of course I regret now.

The 60 used gigs on the drive made up around 12000 tracks, a small collection I'm sure by many standards but big enough that I considered a professional data recovery solution. So I contacted ABC Data Recovery and after a few phone calls and email exchanges I sent the drive off with the initial diagnosis of "degraded media" with a quote £269+vat, a good chunk of money but justifiable I thought thinking of all my perfectly formatted id3 tags. I can't recall the exact ins and outs of the conversation but apparently degraded media was a common enough problem and they were confident of a full recovery without even opening the drive.

After they physically inspected it however it turns out that one of the drive heads was damaged, and recovery now would involve acquiring an identical drive, and exchanging parts in a certified clean room, etc. Even if I supplied the second identical drive (I bought them as a pair oh so long ago) still the quote now was near the £500 mark. As much as I missed my music I couldn't justify that expense, so had the drive shipped back. Since then I've spent around £500 on a new machine and £200 turning the old one into a WHS box (better late than never). I now have a couple of terabytes of storage and no music to store

Having read THIS I am going to attempt it myself since at this point all I'd be losing is one more 80gig sata which is probably near the end of its life anyway. So besides expressing a long winded morale here of "backup today, not tomorrow" I come to the point of this thread...advice please. I'm thinking I'm pretty much in the same boat as that guy was with one drive that works fine and another with damaged heads, so swapping the platters would be the easiest solution (I imagine swapping the heads be nigh on impossible).

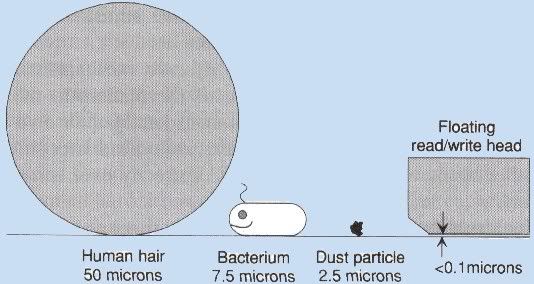

I plan on trying this on the trusty kitchen table with a fan blowing horizontally and slightly up to help reduce dust that may fall on the drive. In the guide linked above you can see the head assembly sits inside a little enclosure which overhangs the platter. However in the image below of a regular desktop hd it looks like the head assembly would be able to move well clear of the platter and I'm hoping my drives follow suit here.

Any thoughts/suggestions on how I should go about this or tools I might need beside torx bits and a needle nose tweezers? The following specs mention besides there being a single platter that there a two heads - does that complicate the job at all, how are they arranged?

EDIT: Help a bro out, last.fm is a poor substitute for my music Any percentage of tracks recovered and I'd consider the exercise worthwhile

Any percentage of tracks recovered and I'd consider the exercise worthwhile

The 60 used gigs on the drive made up around 12000 tracks, a small collection I'm sure by many standards but big enough that I considered a professional data recovery solution. So I contacted ABC Data Recovery and after a few phone calls and email exchanges I sent the drive off with the initial diagnosis of "degraded media" with a quote £269+vat, a good chunk of money but justifiable I thought thinking of all my perfectly formatted id3 tags. I can't recall the exact ins and outs of the conversation but apparently degraded media was a common enough problem and they were confident of a full recovery without even opening the drive.

After they physically inspected it however it turns out that one of the drive heads was damaged, and recovery now would involve acquiring an identical drive, and exchanging parts in a certified clean room, etc. Even if I supplied the second identical drive (I bought them as a pair oh so long ago) still the quote now was near the £500 mark. As much as I missed my music I couldn't justify that expense, so had the drive shipped back. Since then I've spent around £500 on a new machine and £200 turning the old one into a WHS box (better late than never). I now have a couple of terabytes of storage and no music to store

Having read THIS I am going to attempt it myself since at this point all I'd be losing is one more 80gig sata which is probably near the end of its life anyway. So besides expressing a long winded morale here of "backup today, not tomorrow" I come to the point of this thread...advice please. I'm thinking I'm pretty much in the same boat as that guy was with one drive that works fine and another with damaged heads, so swapping the platters would be the easiest solution (I imagine swapping the heads be nigh on impossible).

I plan on trying this on the trusty kitchen table with a fan blowing horizontally and slightly up to help reduce dust that may fall on the drive. In the guide linked above you can see the head assembly sits inside a little enclosure which overhangs the platter. However in the image below of a regular desktop hd it looks like the head assembly would be able to move well clear of the platter and I'm hoping my drives follow suit here.

Any thoughts/suggestions on how I should go about this or tools I might need beside torx bits and a needle nose tweezers? The following specs mention besides there being a single platter that there a two heads - does that complicate the job at all, how are they arranged?

EDIT: Help a bro out, last.fm is a poor substitute for my music

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)