Leadslinger

n00b

- Joined

- Aug 4, 2005

- Messages

- 48

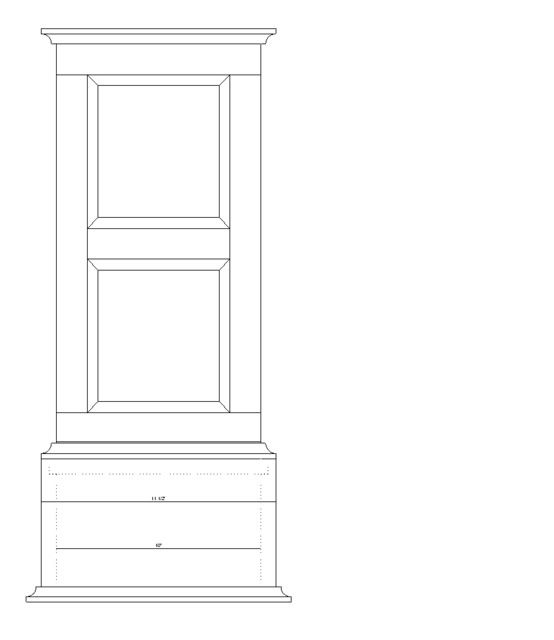

Fantastic work M8, If you aren't a finish carpenter by trade, you sure could be. I haven't seen fine cabinet building like that done since my Dad retired from contracting. Anyone can build a box, but skills are truly appreciated.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)