civic00typer

Gawd

- Joined

- Dec 5, 2003

- Messages

- 517

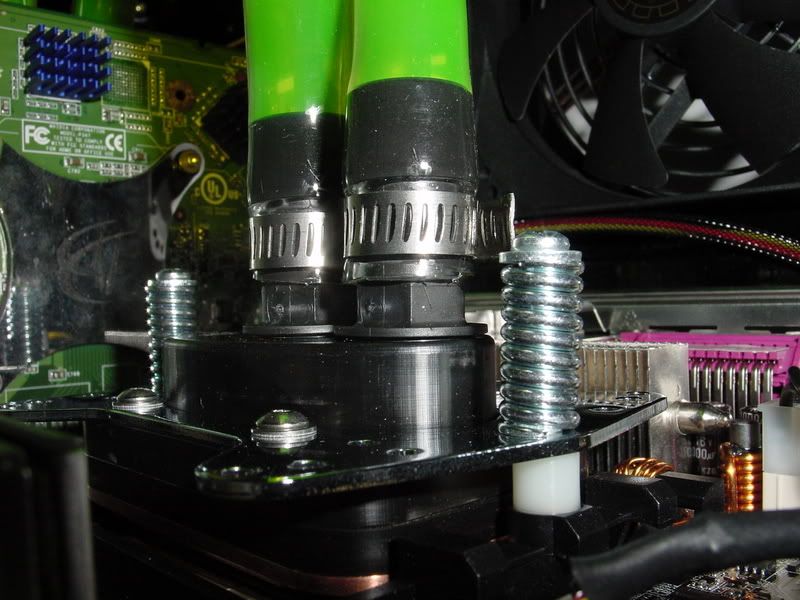

As many of you may know by my previous threads, I assembled a water cooled Core 2 Duo E6400 rig last weekend. I leak tested the water cooling loop for 2 days, and ran the system for 3 days without any problems. Last night while I was using the computer the video card started to produce artifacts. I quickly shut down the system and noticed a half-dollar sized puddle at the bottom of my case, which was caused by what I believe to be a faulty barb or o-ring seal on the Apogee water block. The pictures of this can be viewed here: Water Block Woes . At this point I am not sure exactly what was damaged due to the leak. The barbs on the water block were torqued to properly compress the o-rings. I can't tell whether the leak was caused by the o-ring or the barb itself. Any ideas?

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)