JSHamlet234

Gawd

- Joined

- Apr 9, 2021

- Messages

- 943

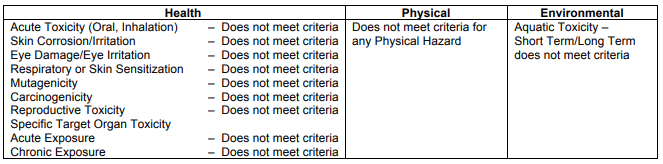

So I mentioned in the thermal paste thread that I ordered some Indium foil to attempt to use like a thermal pad. Well it's here, and I had to chance to run it against my new favorite thermal paste.

The sheet I received was 100mm x 100mm x 0.2mm. It cost me $20, and it's enough to do 9 CPUs, so at ~$2 per application, it's not the most expensive TIM I've ever used, but it's definitely not the cheapest either.

First things first - 0.2mm is a little thicker than I thought it would be, but it ensures that it will be thick enough to provide consistent contact.

Test Bed:

Intel 5960X @ 4.2GHz / 1.175V manual voltage, all EIST and C-States disabled

ASUS X99-A USB 3.1 Motherboard, BIOS 3701

EVGA CLC 280mm mounted as front exhaust

4X Arctic P14 PWM rad fans in push/pull @1470RPM (90% PWM)

Coolermaster HAF-XB EVO with Noctua A20 Chromax top intake fan @ 810RPM (90% PWM)

Prime 95 26.6 Small FFTs

15 minute run time to ensure steady state

Ambient temperature measured 3 inches from top intake fan.

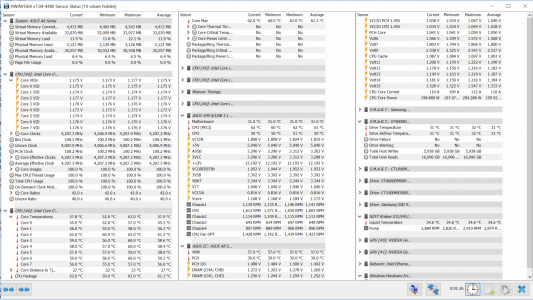

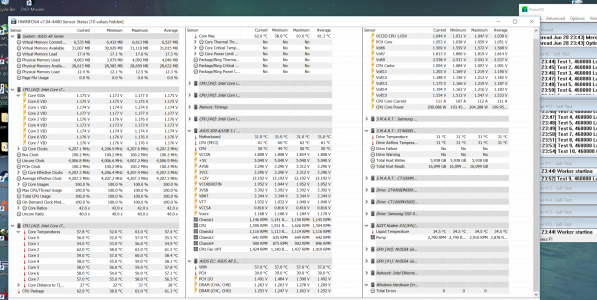

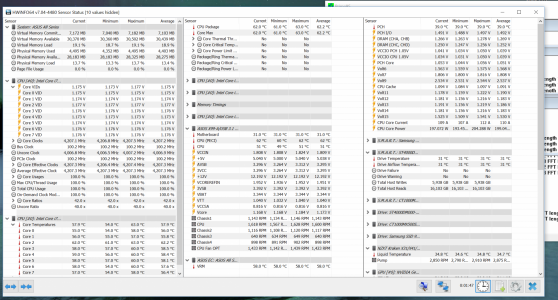

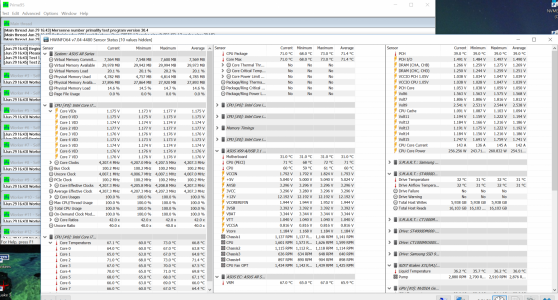

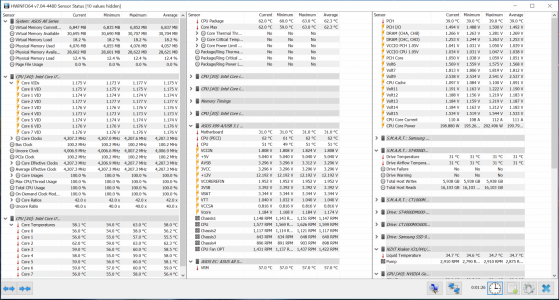

Temperatures reported are an average over the final 60 seconds as reported by HWINFO64.

Arctic MX-5

Ambient Temp: 23.6C

Water Temp: 31.6C

Package Temp: 61.7C

Cores: 54.4, 53.6, 61.7, 56.9, 58.0, 57.3, 58.6, 54.6

Delta from ambient temp: 38.1C

Delta from water Temp: 30.1C

Average Power: 198.0 watts

Thermal Resistance (system): 0.19242 C/watt

Indium Foil [0.2mm thickness]

Ambient Temp: 23.8C

Water Temp: 31.6C

Package Temp: 60.5C

Cores: 53.3, 54.1, 60.5, 58.0, 57.7, 57.8, 57.5, 55.1

Delta from ambient temp: 36.7C

Delta from water temp: 28.9C

Average Power: 197.5 watts

Thermal Resistance (system): 0.18582 C/watt

The improvement over good paste was 1.4C - this is about the same improvement I would have expected from liquid metal based on my previous testing.

I'm gonna chalk this one up in the WIN column.

The sheet I received was 100mm x 100mm x 0.2mm. It cost me $20, and it's enough to do 9 CPUs, so at ~$2 per application, it's not the most expensive TIM I've ever used, but it's definitely not the cheapest either.

First things first - 0.2mm is a little thicker than I thought it would be, but it ensures that it will be thick enough to provide consistent contact.

Test Bed:

Intel 5960X @ 4.2GHz / 1.175V manual voltage, all EIST and C-States disabled

ASUS X99-A USB 3.1 Motherboard, BIOS 3701

EVGA CLC 280mm mounted as front exhaust

4X Arctic P14 PWM rad fans in push/pull @1470RPM (90% PWM)

Coolermaster HAF-XB EVO with Noctua A20 Chromax top intake fan @ 810RPM (90% PWM)

Prime 95 26.6 Small FFTs

15 minute run time to ensure steady state

Ambient temperature measured 3 inches from top intake fan.

Temperatures reported are an average over the final 60 seconds as reported by HWINFO64.

Arctic MX-5

Ambient Temp: 23.6C

Water Temp: 31.6C

Package Temp: 61.7C

Cores: 54.4, 53.6, 61.7, 56.9, 58.0, 57.3, 58.6, 54.6

Delta from ambient temp: 38.1C

Delta from water Temp: 30.1C

Average Power: 198.0 watts

Thermal Resistance (system): 0.19242 C/watt

Indium Foil [0.2mm thickness]

Ambient Temp: 23.8C

Water Temp: 31.6C

Package Temp: 60.5C

Cores: 53.3, 54.1, 60.5, 58.0, 57.7, 57.8, 57.5, 55.1

Delta from ambient temp: 36.7C

Delta from water temp: 28.9C

Average Power: 197.5 watts

Thermal Resistance (system): 0.18582 C/watt

The improvement over good paste was 1.4C - this is about the same improvement I would have expected from liquid metal based on my previous testing.

I'm gonna chalk this one up in the WIN column.

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)