Foe-hammer

Limp Gawd

- Joined

- Feb 1, 2006

- Messages

- 186

Can frequently switching between multiple resolutions on the FW900 cause it to fail (harder on the monitor)? I've recently "upgraded" from an HDFuryX3 to a Startech DP2VGAHD20 adapter to use with my FW900. Before, with the HDFury adapter, I was limited to just 1920x1200 @ 60 Hz resolution. With the Startech, I'm able to use a number of different higher resolutions and refresh rates. Depending on the game or application, I've frequently been switching between 1920x1200@95, 2304x1440@70, and 2506x1600@60. With the FW900 and CRTs in general, switching between resolutions seems to be akin to turning the monitor on/off repeatedly. Can this potentially reduce the life on the monitor?

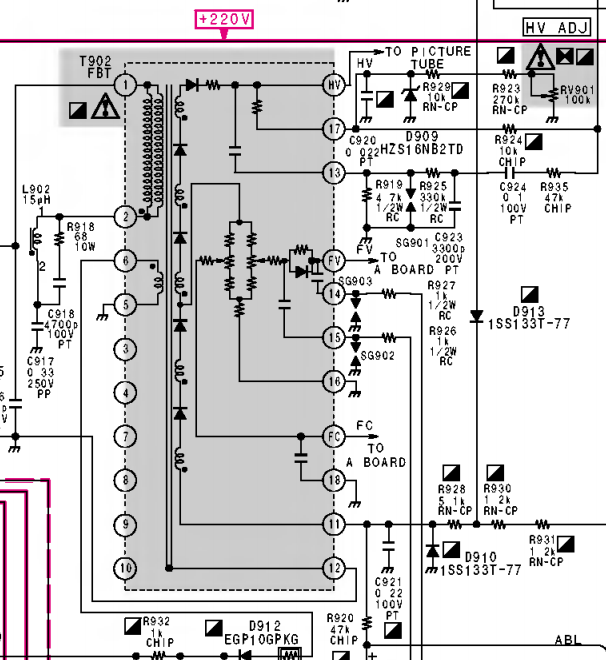

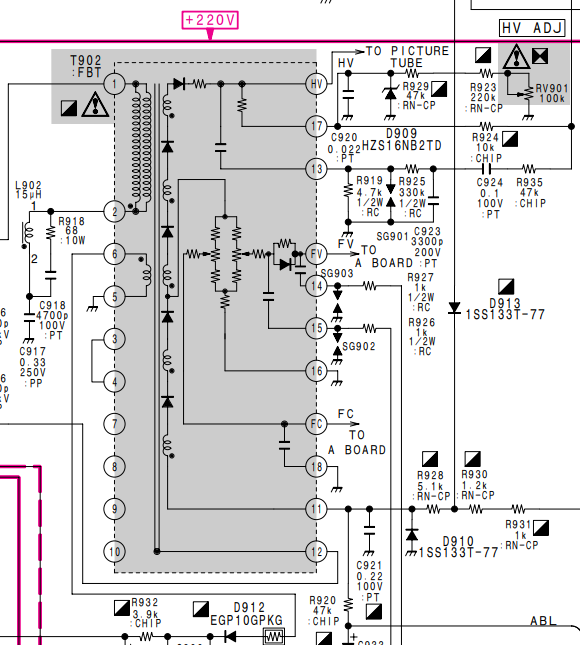

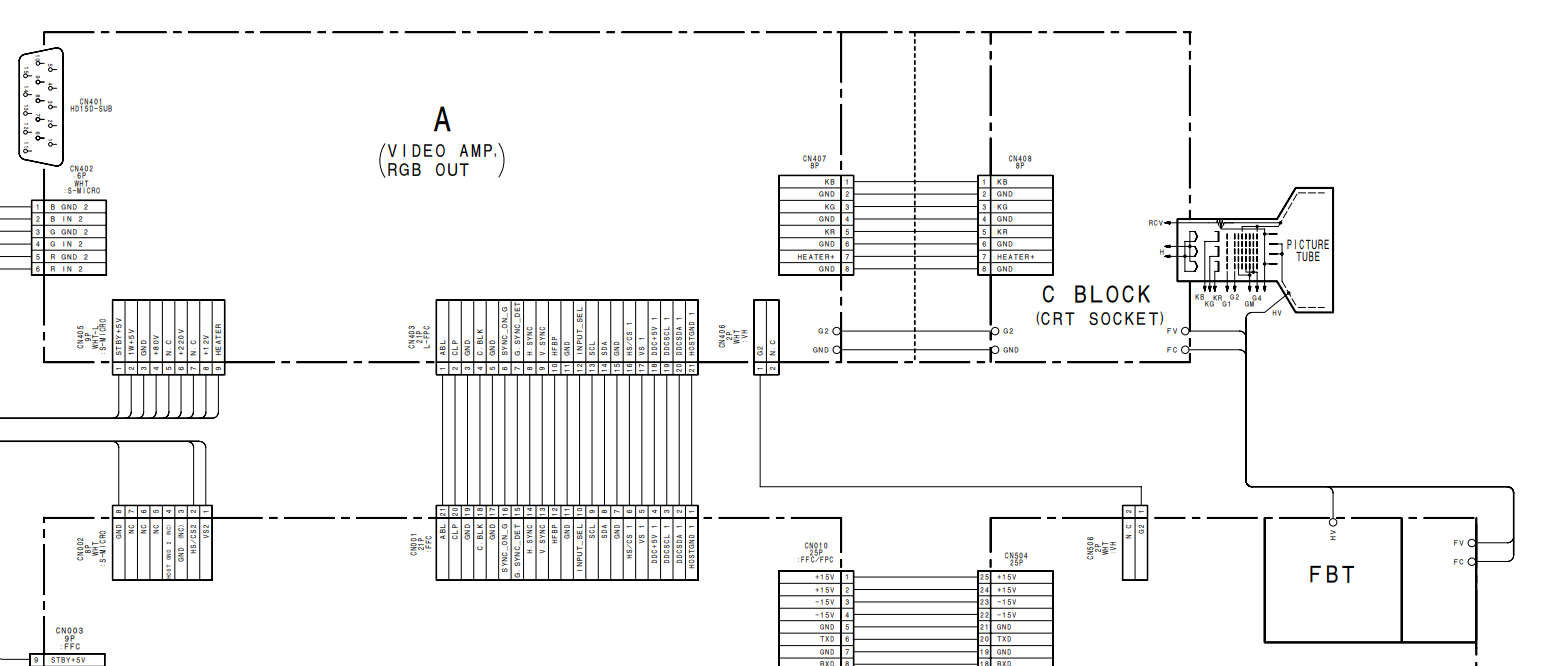

Also, a few weeks ago, when playing at 19200x1200@95, all of a sudden I got an odd static-like interference that crept into the image. The image then reset momentarily, and when it came back the picture was abnormally dark and it did not fit the entire screen anymore (I had previously adjusted the image to fill the entire screen perfectly). I then started to smell electrical burn. I immediately turned off and unplugged everything on the monitor and let it sit for a week. I then took off all the FW900 housing and blew the entire monitor out (almost 20 years of dust build-up!). I then replaced the power cable and reverted back to the HDFury adapter and started it up. Everything is fine so far. No image problems or electrical burn smell. So I don't know if it was something that failed on the monitor or the Startech adapter. I wonder if pushing the FW900 at higher resolutions/refresh rates or frequently changing resolutions caused this to happen?

Also, a few weeks ago, when playing at 19200x1200@95, all of a sudden I got an odd static-like interference that crept into the image. The image then reset momentarily, and when it came back the picture was abnormally dark and it did not fit the entire screen anymore (I had previously adjusted the image to fill the entire screen perfectly). I then started to smell electrical burn. I immediately turned off and unplugged everything on the monitor and let it sit for a week. I then took off all the FW900 housing and blew the entire monitor out (almost 20 years of dust build-up!). I then replaced the power cable and reverted back to the HDFury adapter and started it up. Everything is fine so far. No image problems or electrical burn smell. So I don't know if it was something that failed on the monitor or the Startech adapter. I wonder if pushing the FW900 at higher resolutions/refresh rates or frequently changing resolutions caused this to happen?

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)