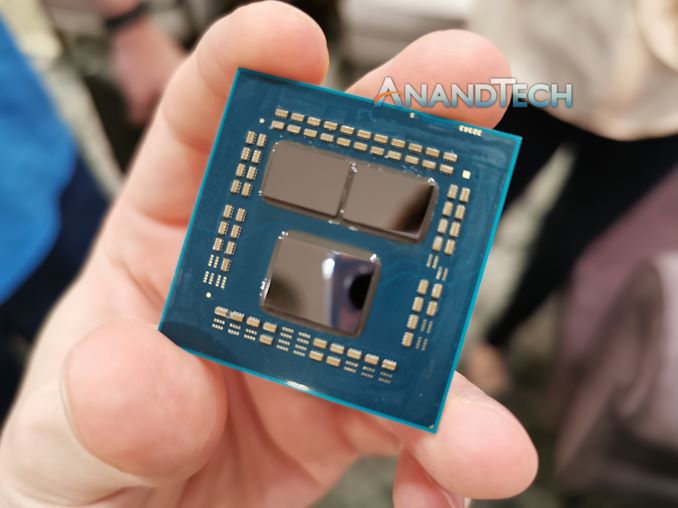

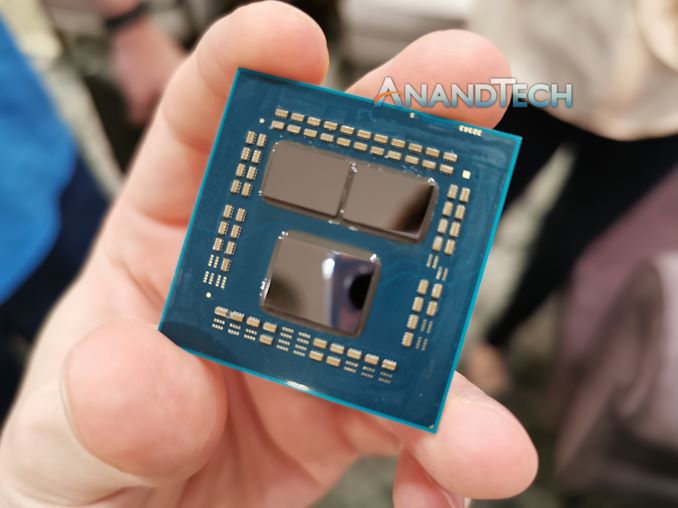

I was looking at the chiplet layout on the ryzen 3950x:

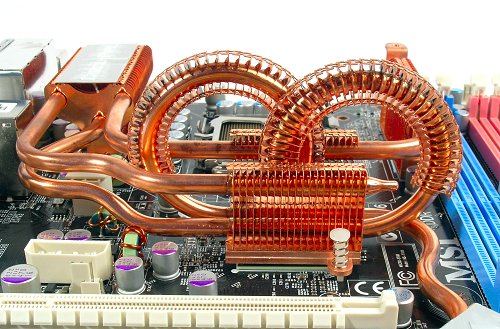

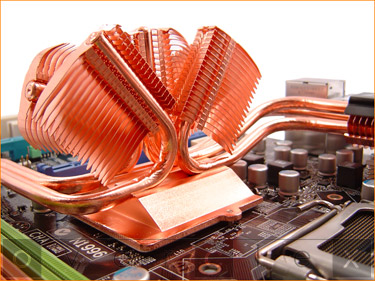

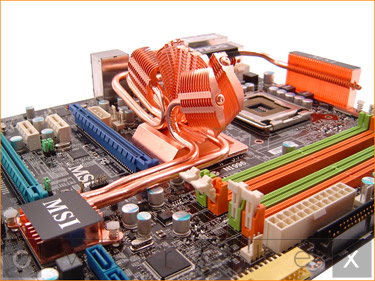

The off-center chiplets got me thinking about heat sink/cold plate orientation and design. Past single chip dies meant concentrated cooling effects in the middle, but with this layout, it looks like some formerly reliable coolers might not be very efficient when mounted on a ryzen 3000 CPU.

The off-center chiplets got me thinking about heat sink/cold plate orientation and design. Past single chip dies meant concentrated cooling effects in the middle, but with this layout, it looks like some formerly reliable coolers might not be very efficient when mounted on a ryzen 3000 CPU.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)