Overblod

Limp Gawd

- Joined

- Mar 28, 2018

- Messages

- 178

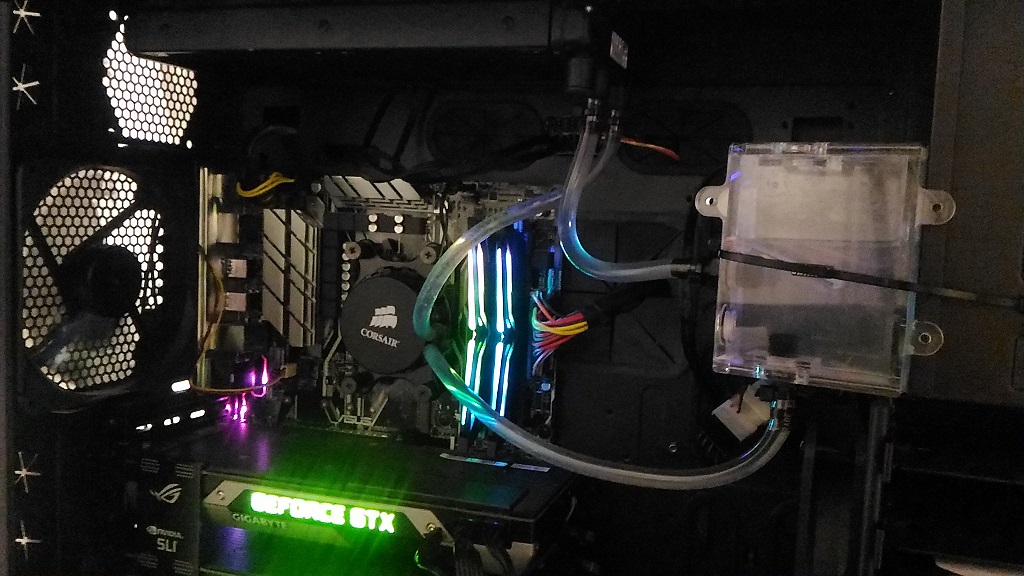

I have a Corsair Hydro series 240mm cooler, its about 1.5 years old, has been running great, cooling performance has not deteriorated/changed, but still, I am wondering, as custom loops use reservoirs or T-links, does AIOs run out of liquid too?

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)