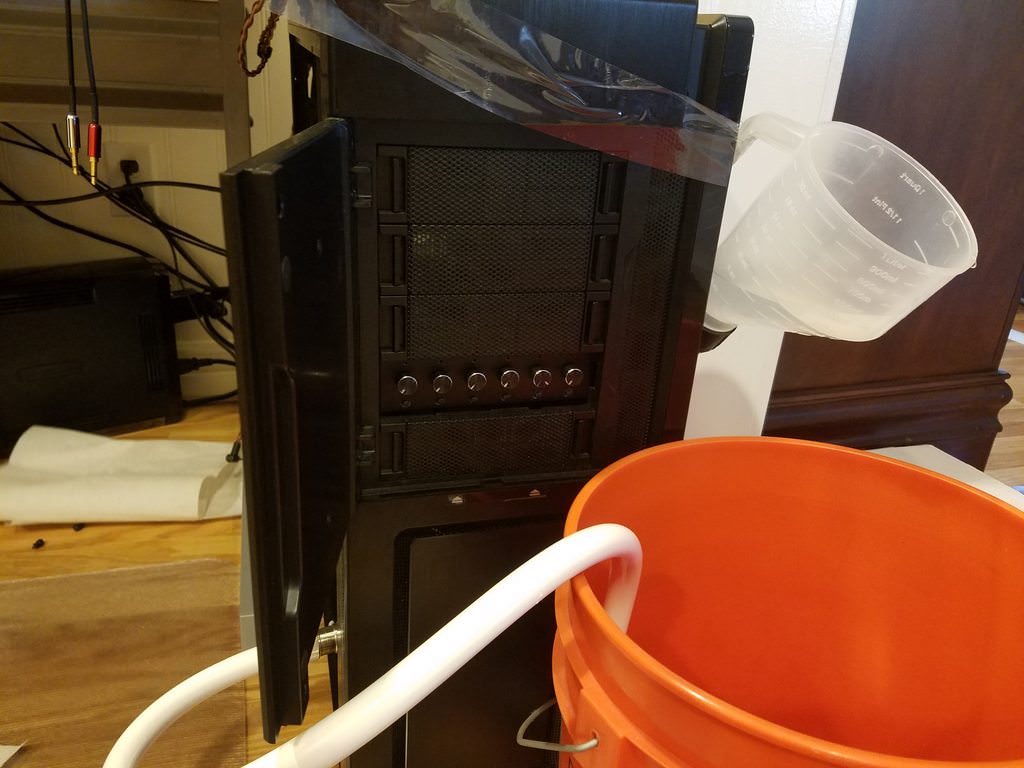

My gaming system is water cooled and runs great - but I had a goal to make it nearly silent. I also wanted to get it to stop dumping tons of heat into my study, especially with summer coming soon. I decided to build a cooling "tower" in my basement (directly below the study), and move the pumps, radiators, and fans there.

It has been quite successful - here's my little build log. I did this primarily to move the heat out of the study and make the computer quieter, not necessarily for better temps, so I don't have any firm benchmarks to share yet (though temps seem as good or better - they are larger radiators after all). I'll work on getting those.

Build log/pictures:

https://imgur.com/a/QTwDXu1

It has been quite successful - here's my little build log. I did this primarily to move the heat out of the study and make the computer quieter, not necessarily for better temps, so I don't have any firm benchmarks to share yet (though temps seem as good or better - they are larger radiators after all). I'll work on getting those.

Build log/pictures:

https://imgur.com/a/QTwDXu1

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)