Hey [H]gang!

I haven't done a build log in YEARS, my professional life has gotten in the way of documenting creativity even though I tend to get the build-itch once a year and part-out an old system to make room for a new one. This year I got the SSF itch. Two years ago I did a SFF build using the NCase M1 (V3) which was friggin sweet, however, it wasn't much of a challenge in terms of cramming hardware in there... and I like a good challenge.

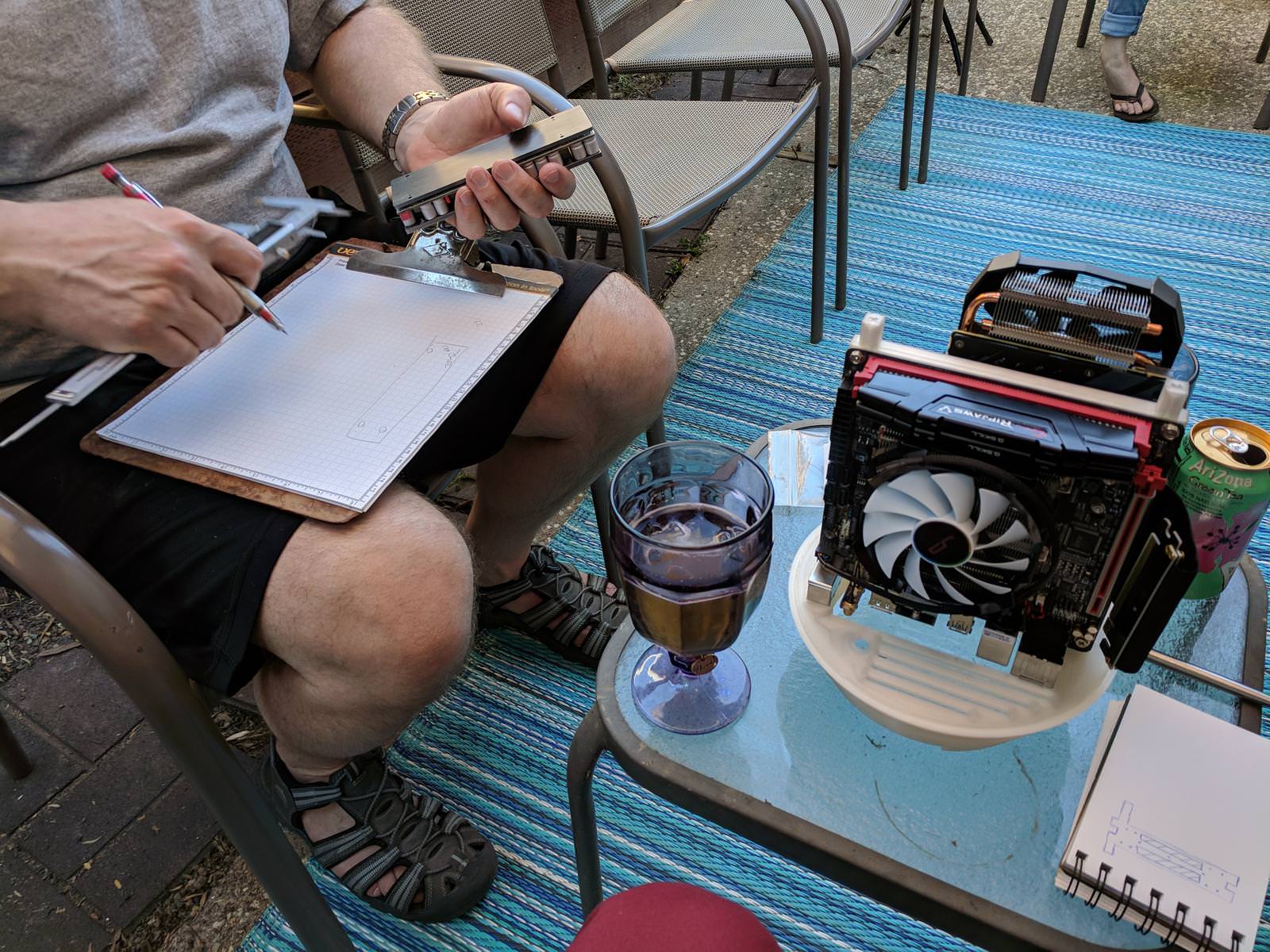

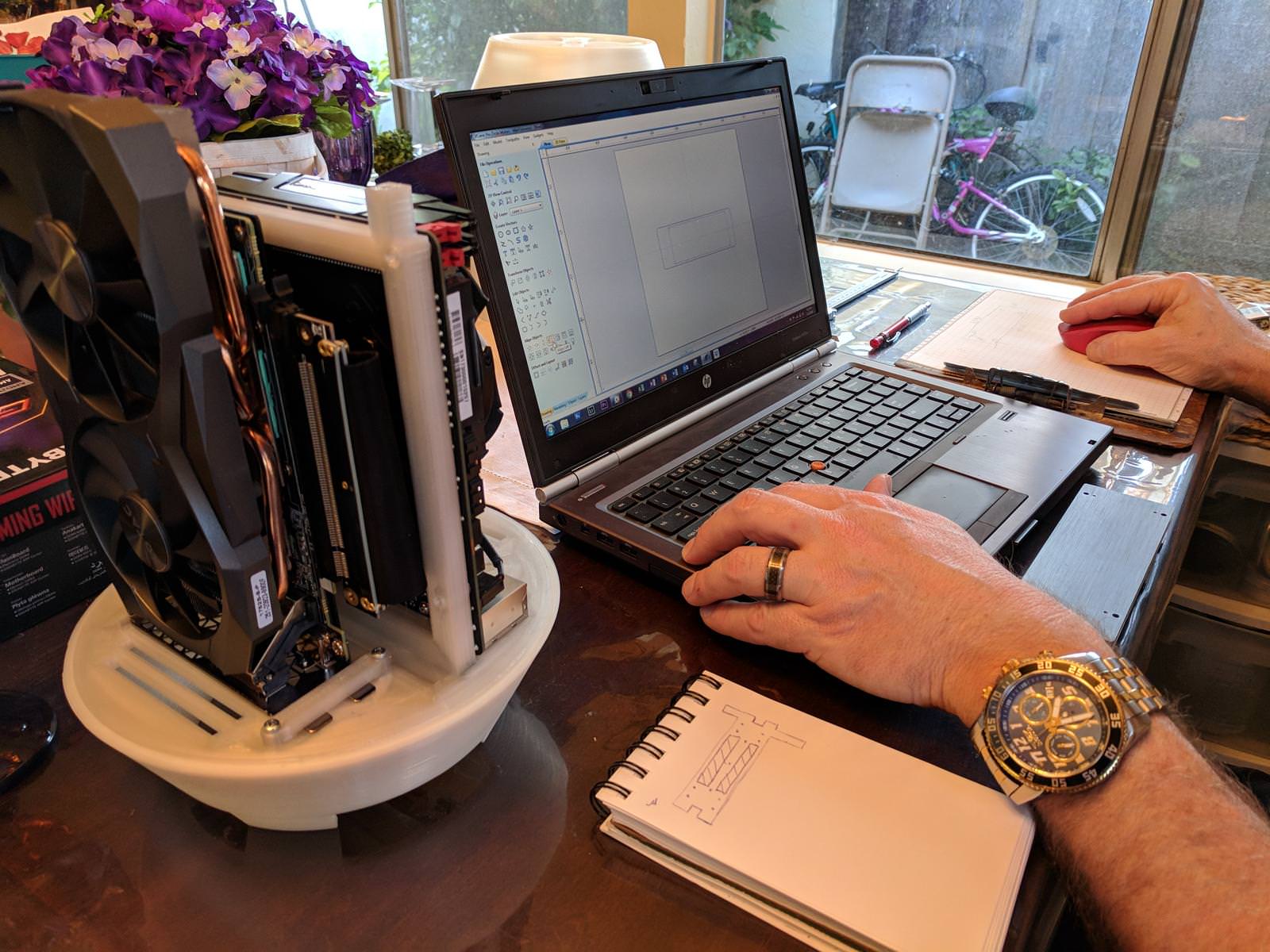

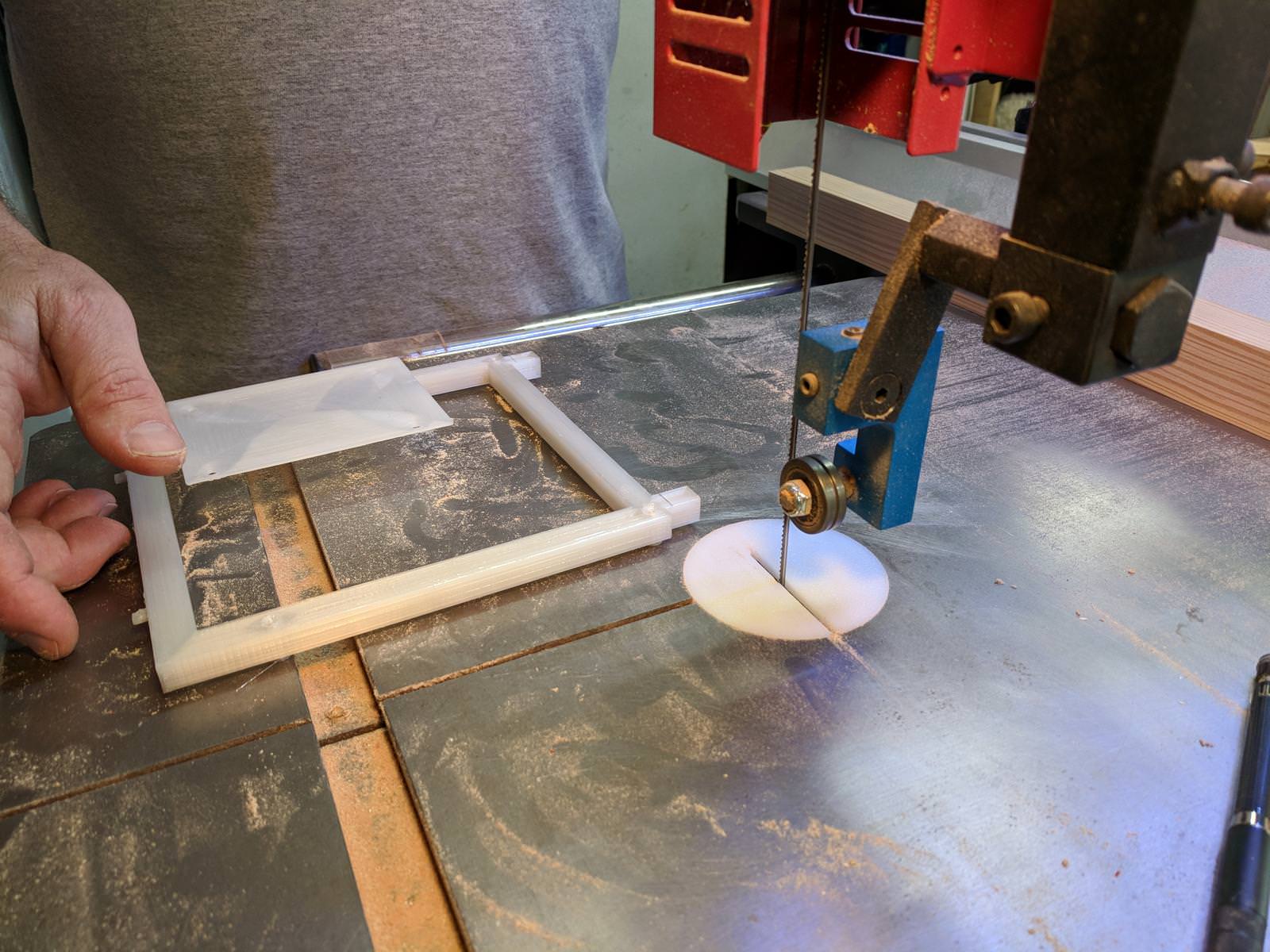

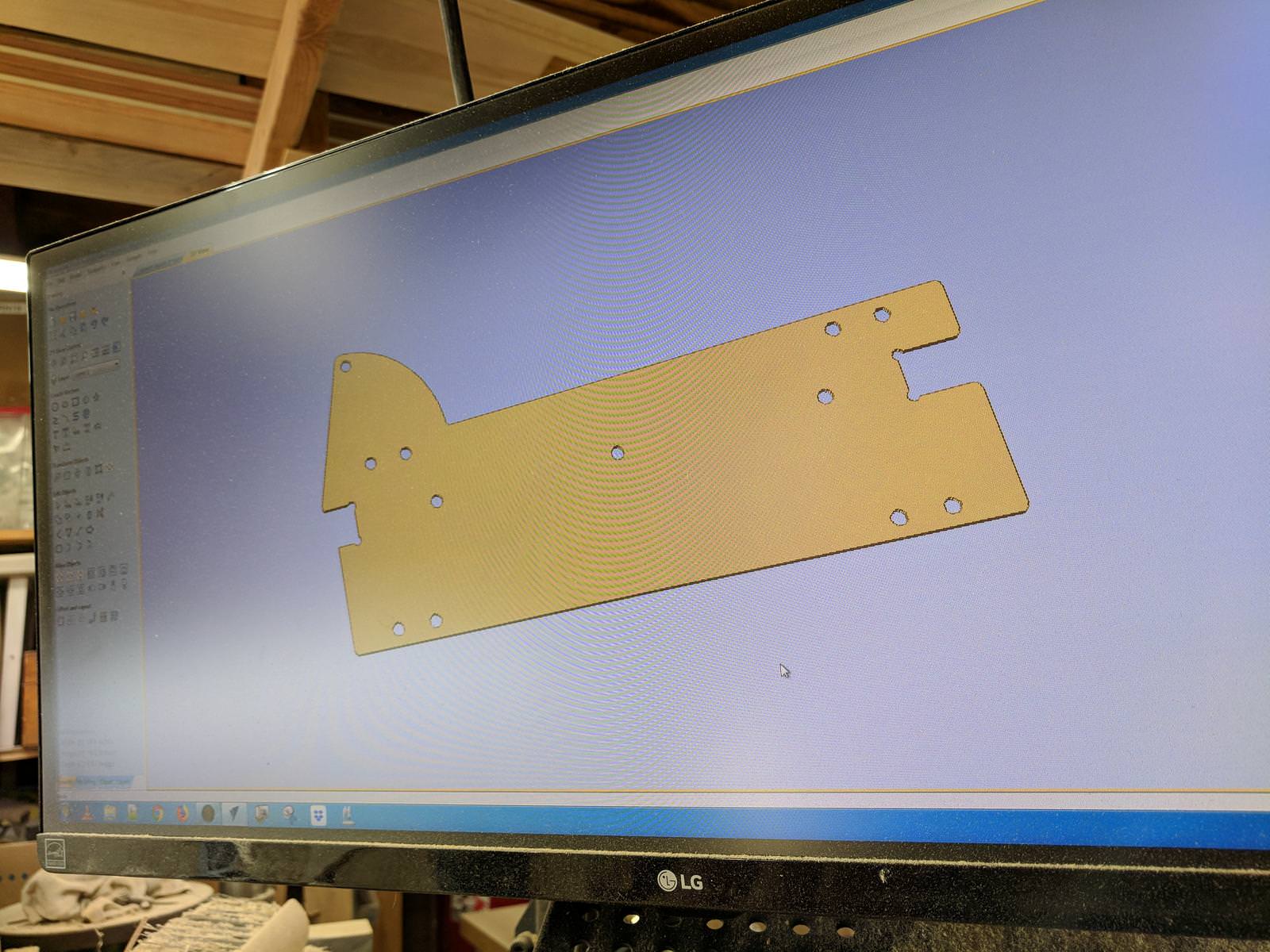

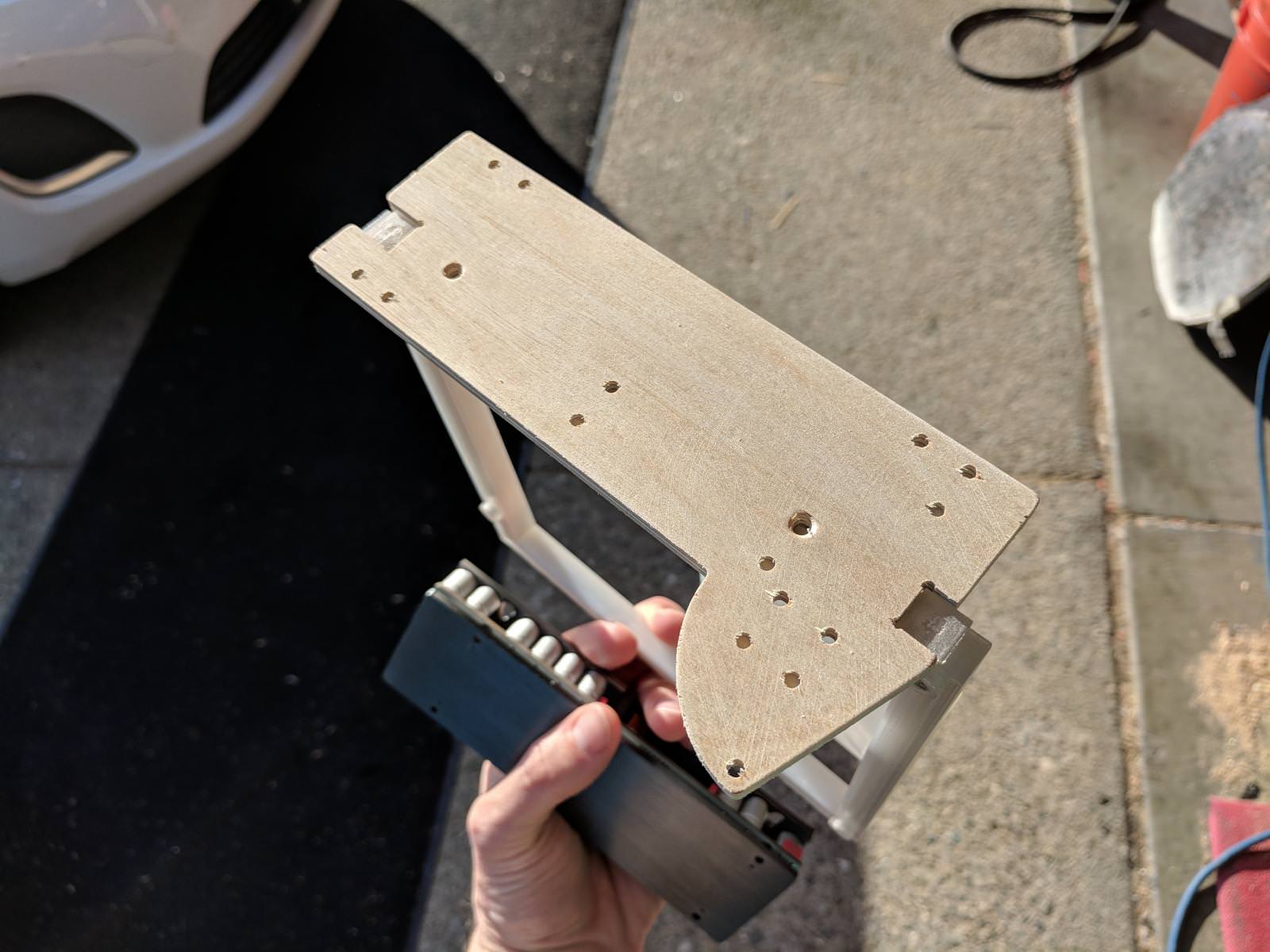

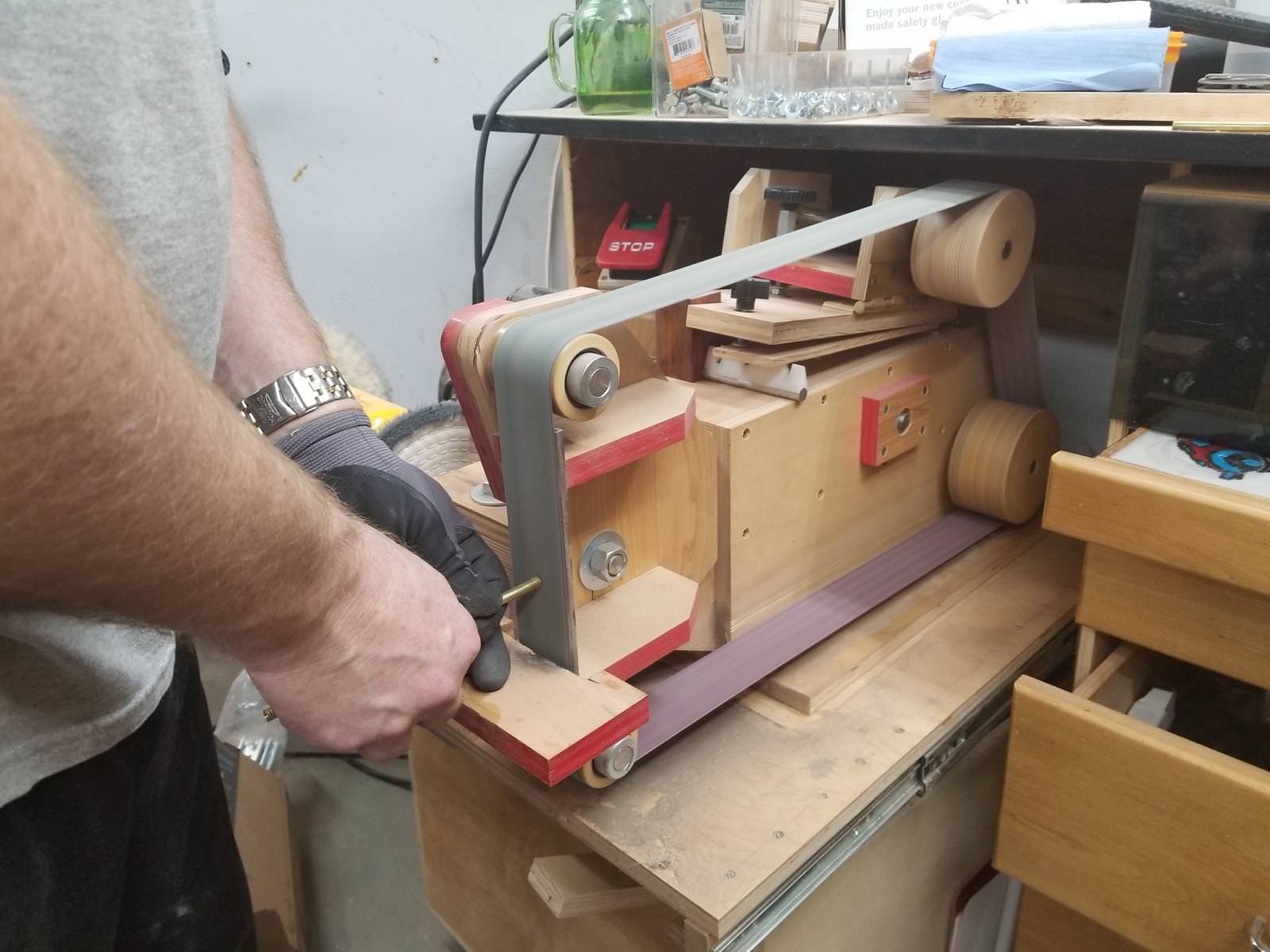

A little about me: I'm in my mid-twenties, I work from home as a Cloud Engineer (AWS) for a local tech company, I am a musician and love being creative in general. I was born and raised here in the Bay Area of CA and grew up in my Father's wood shop. I mention that because you'll see some of his handy work here later.

Down to business:

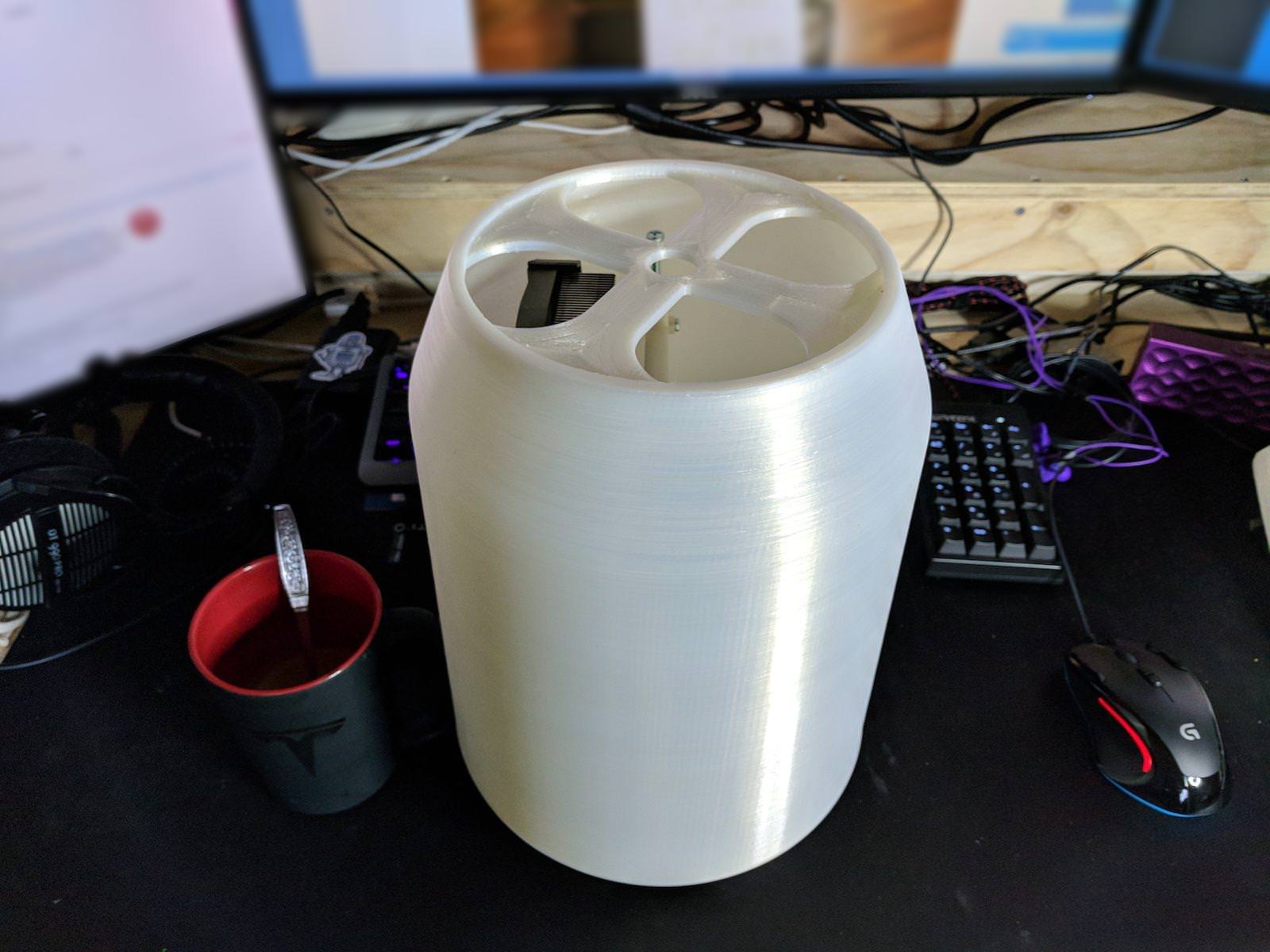

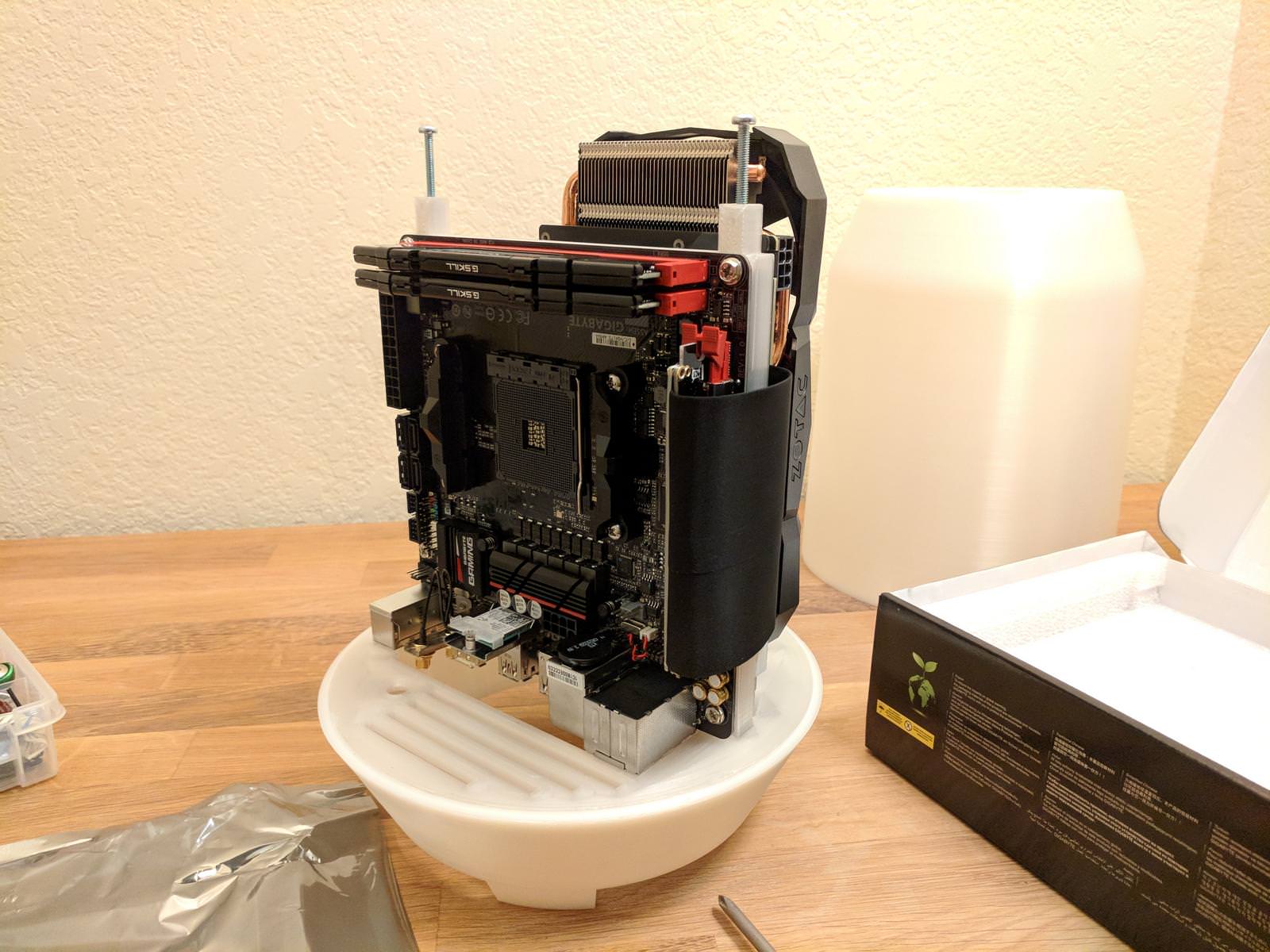

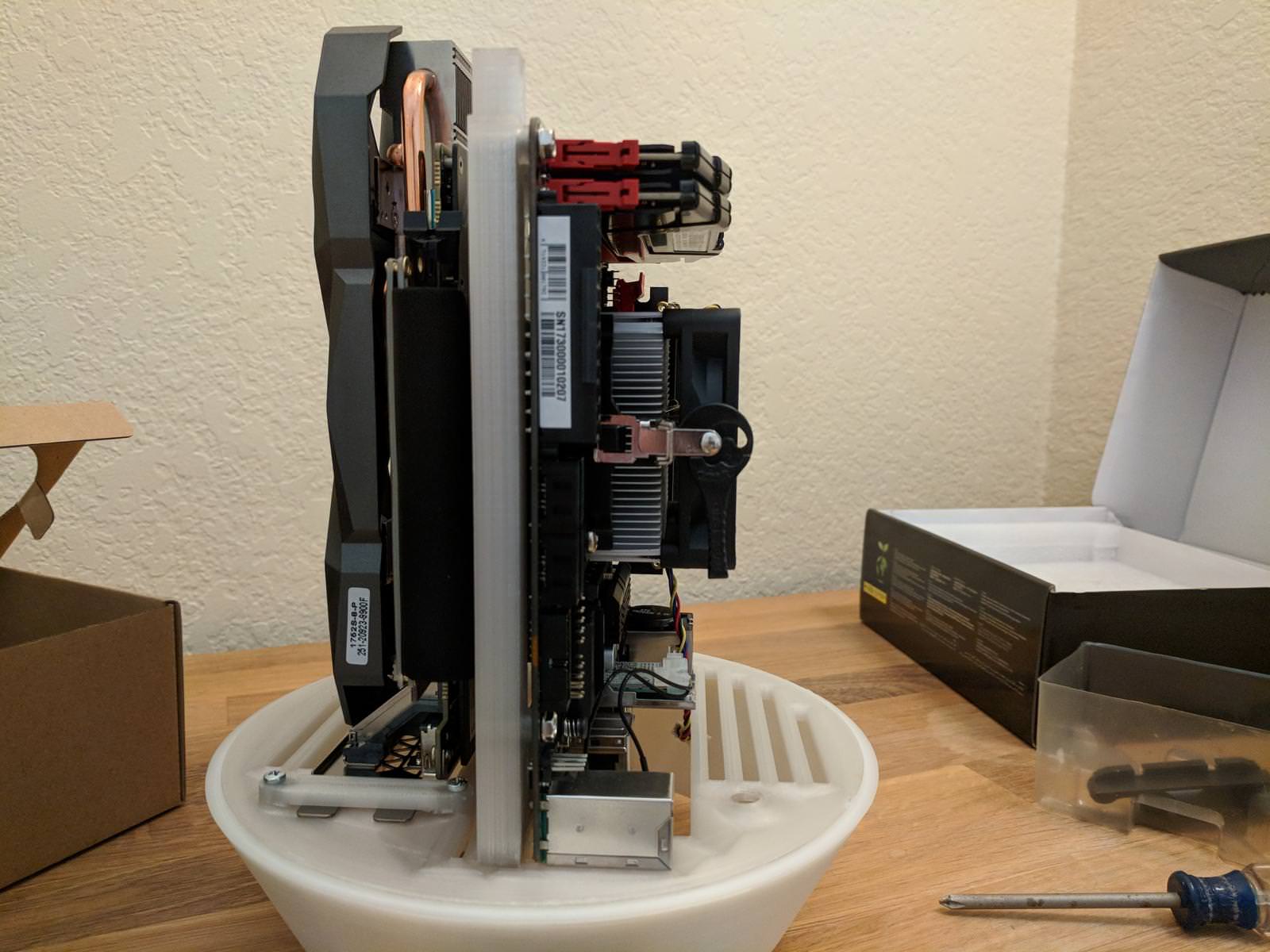

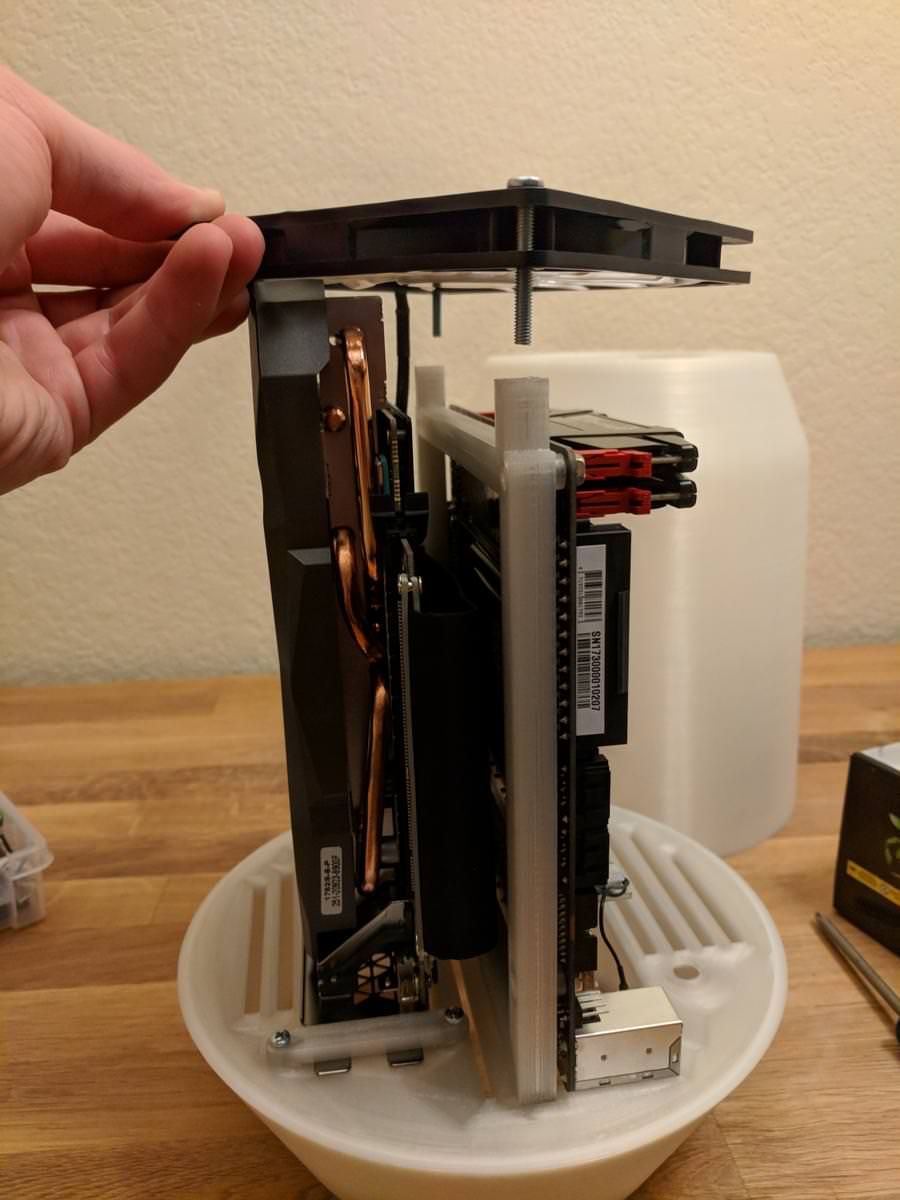

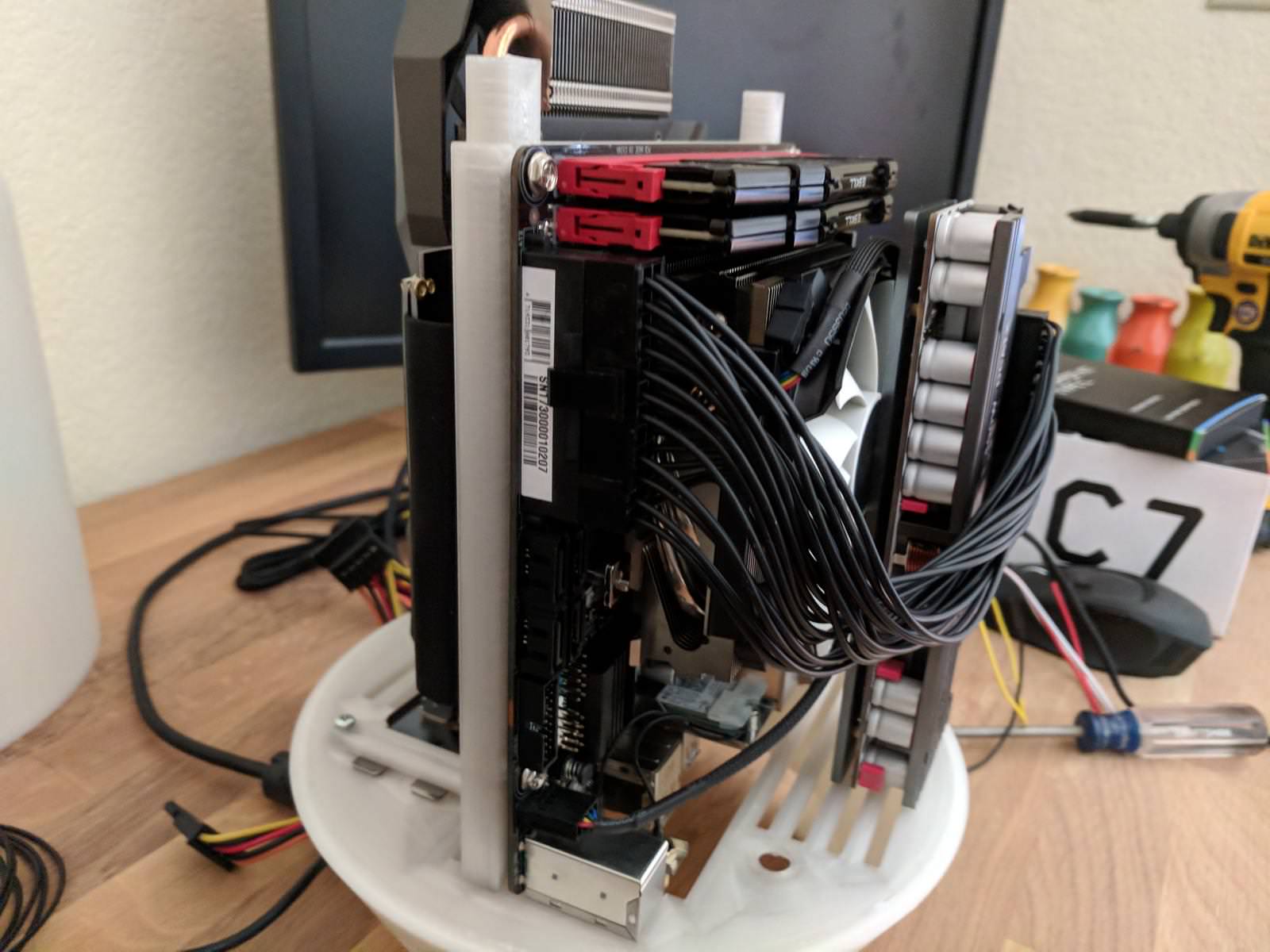

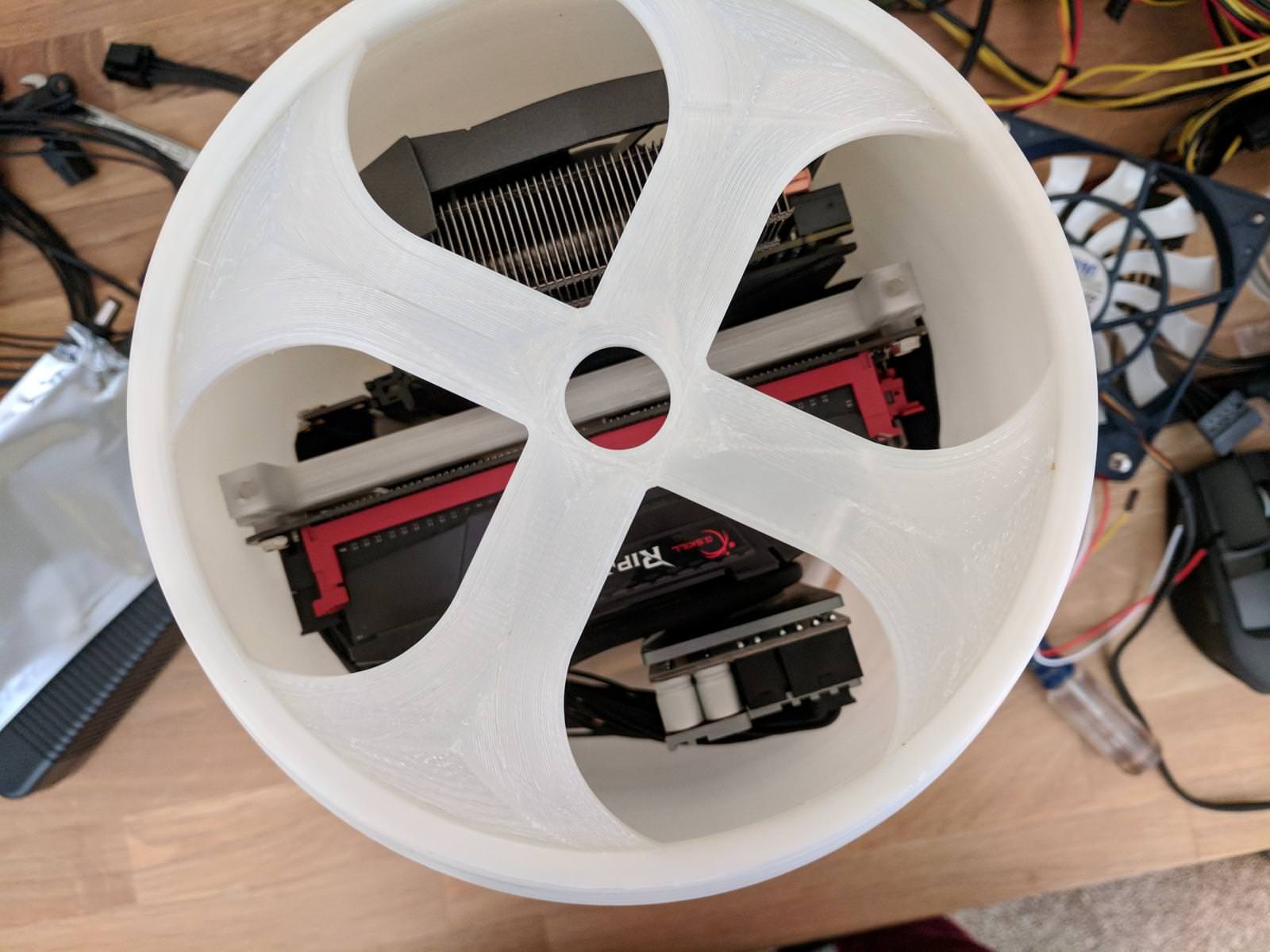

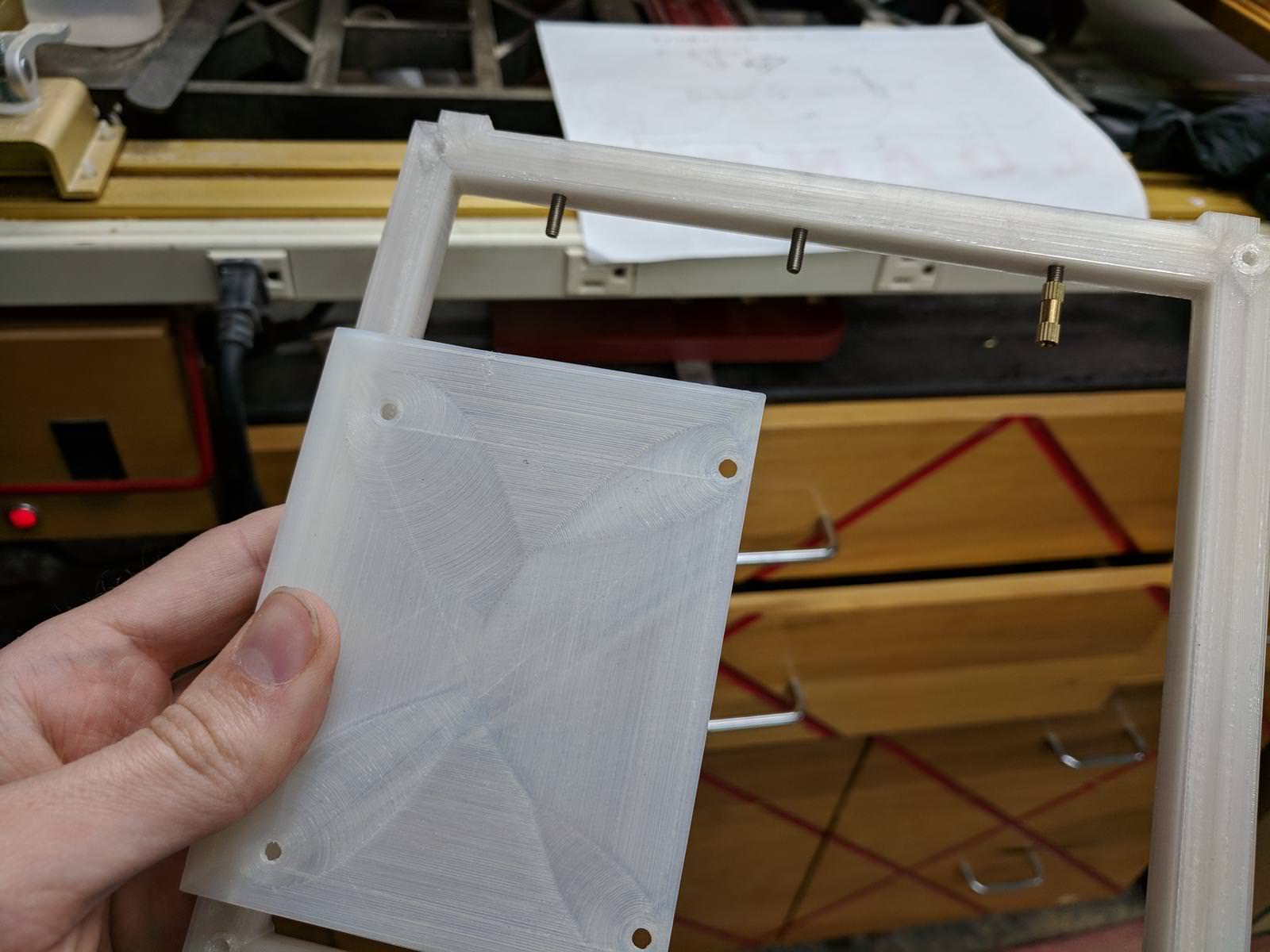

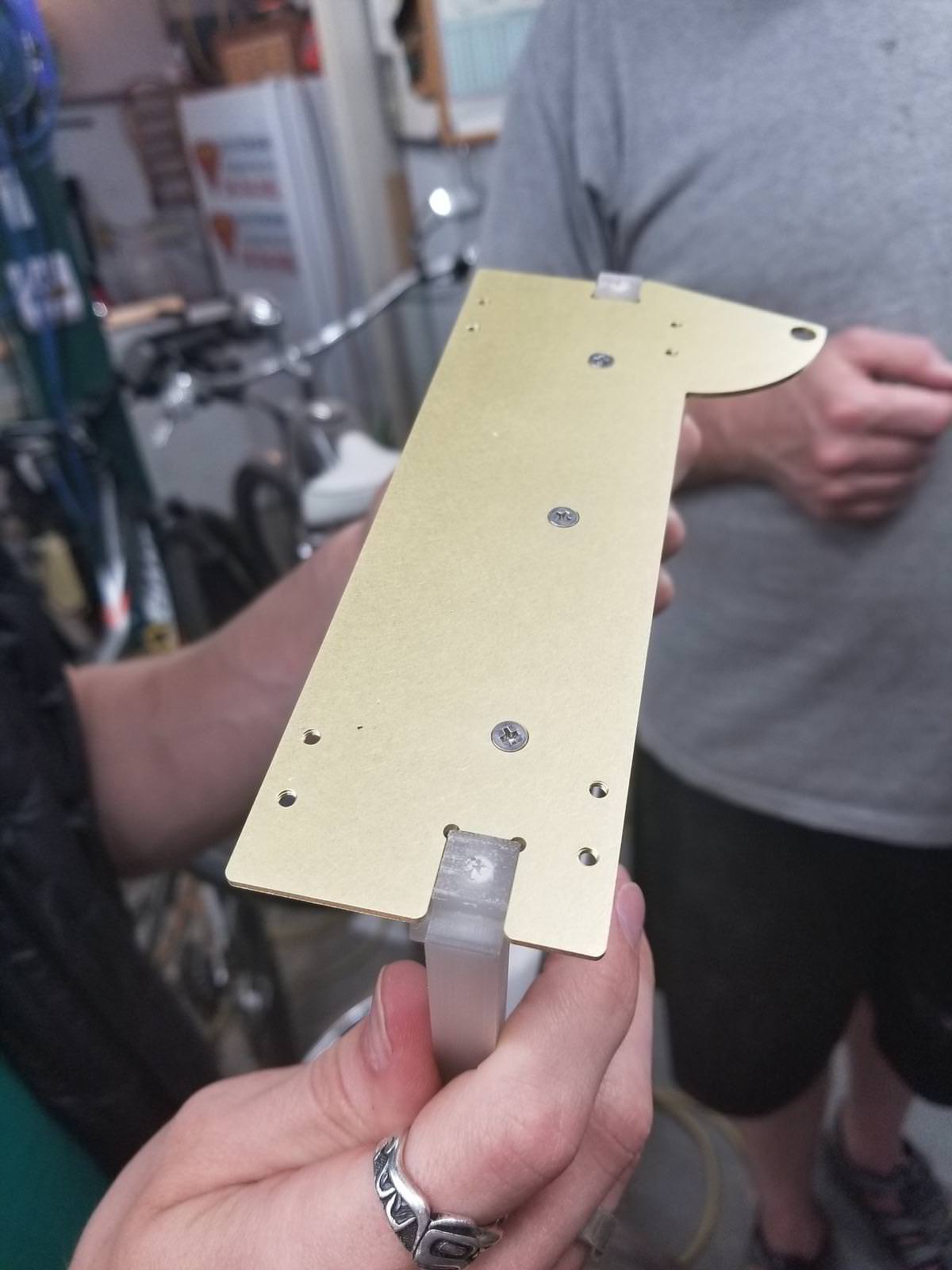

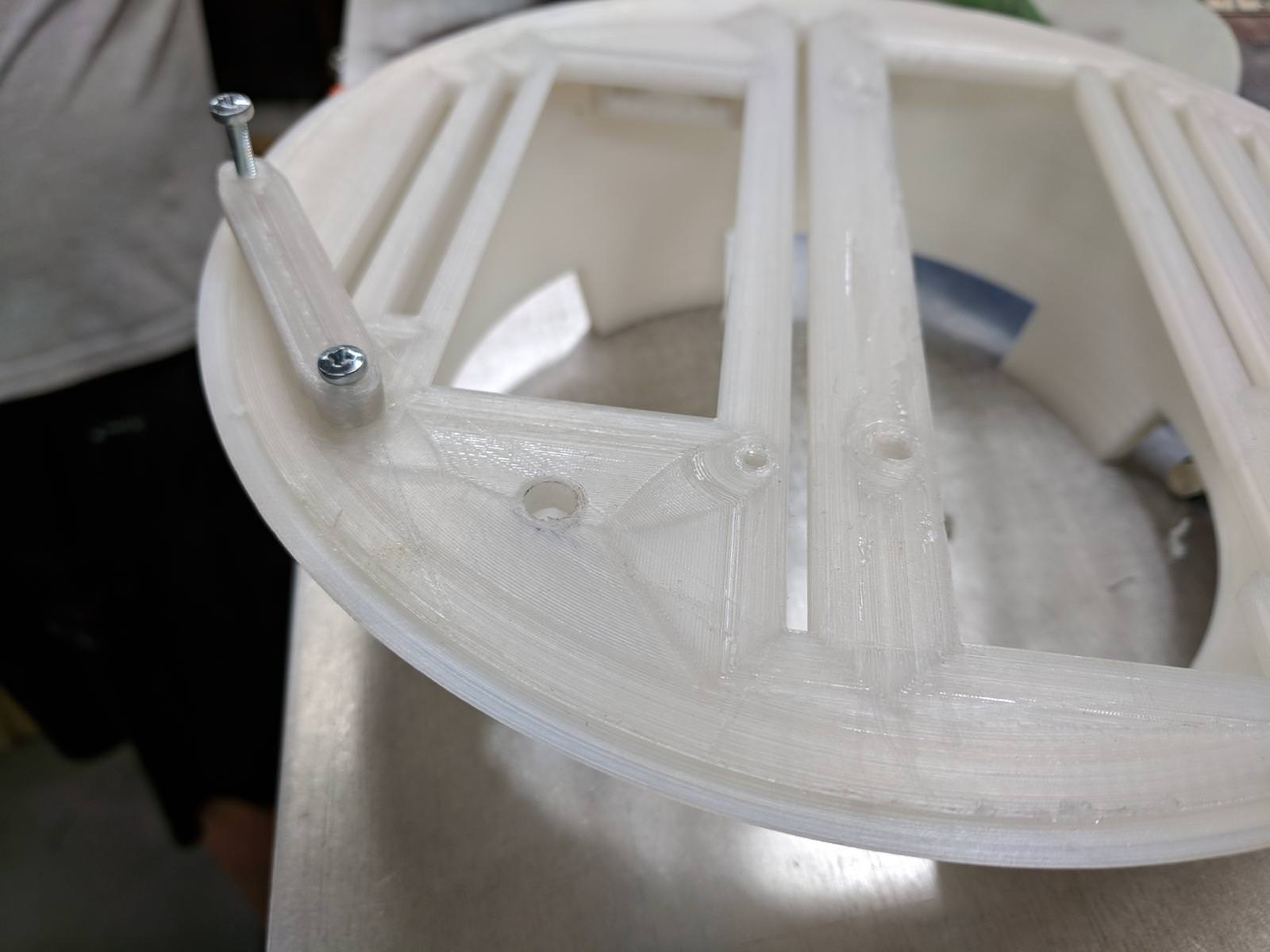

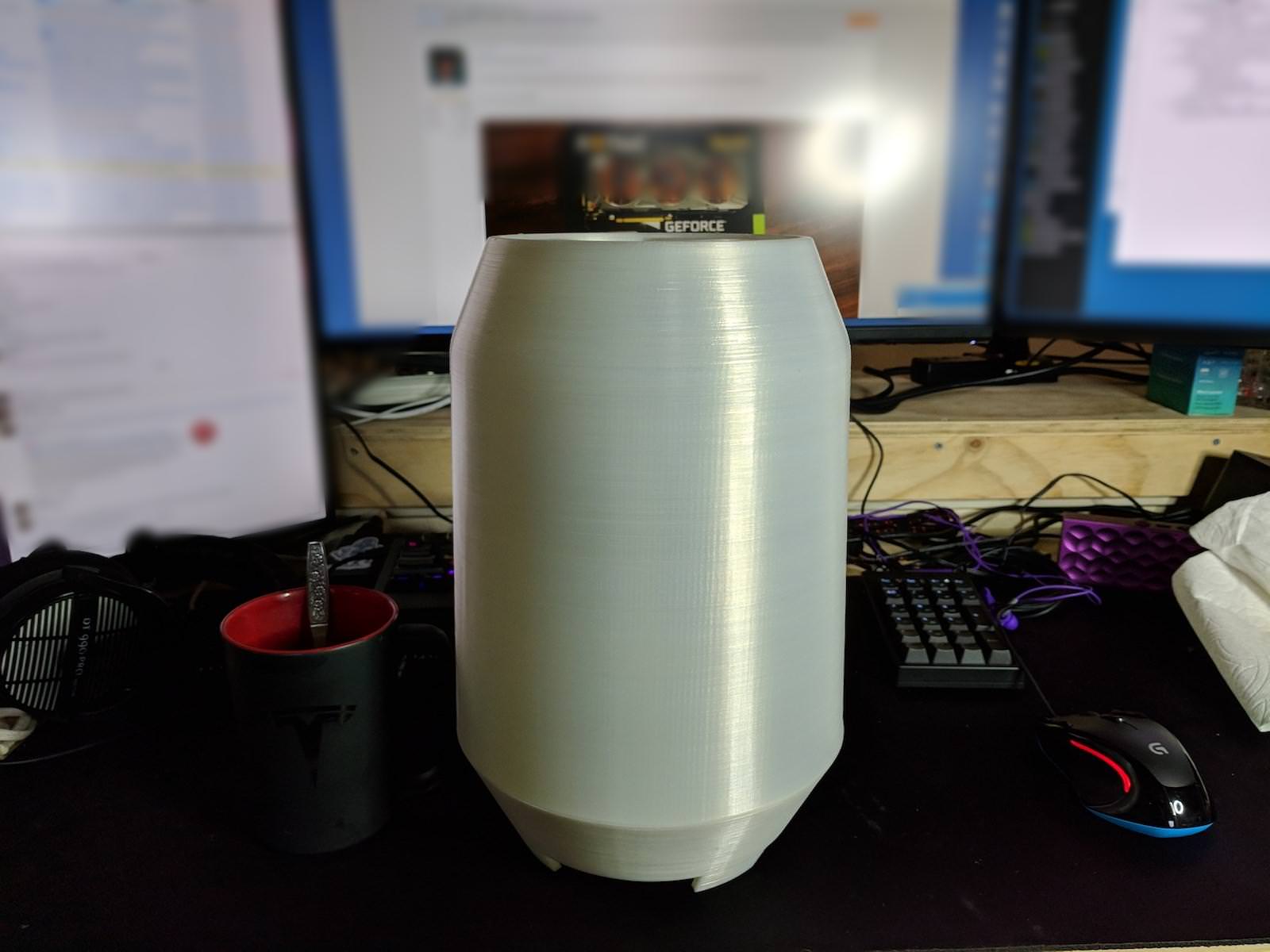

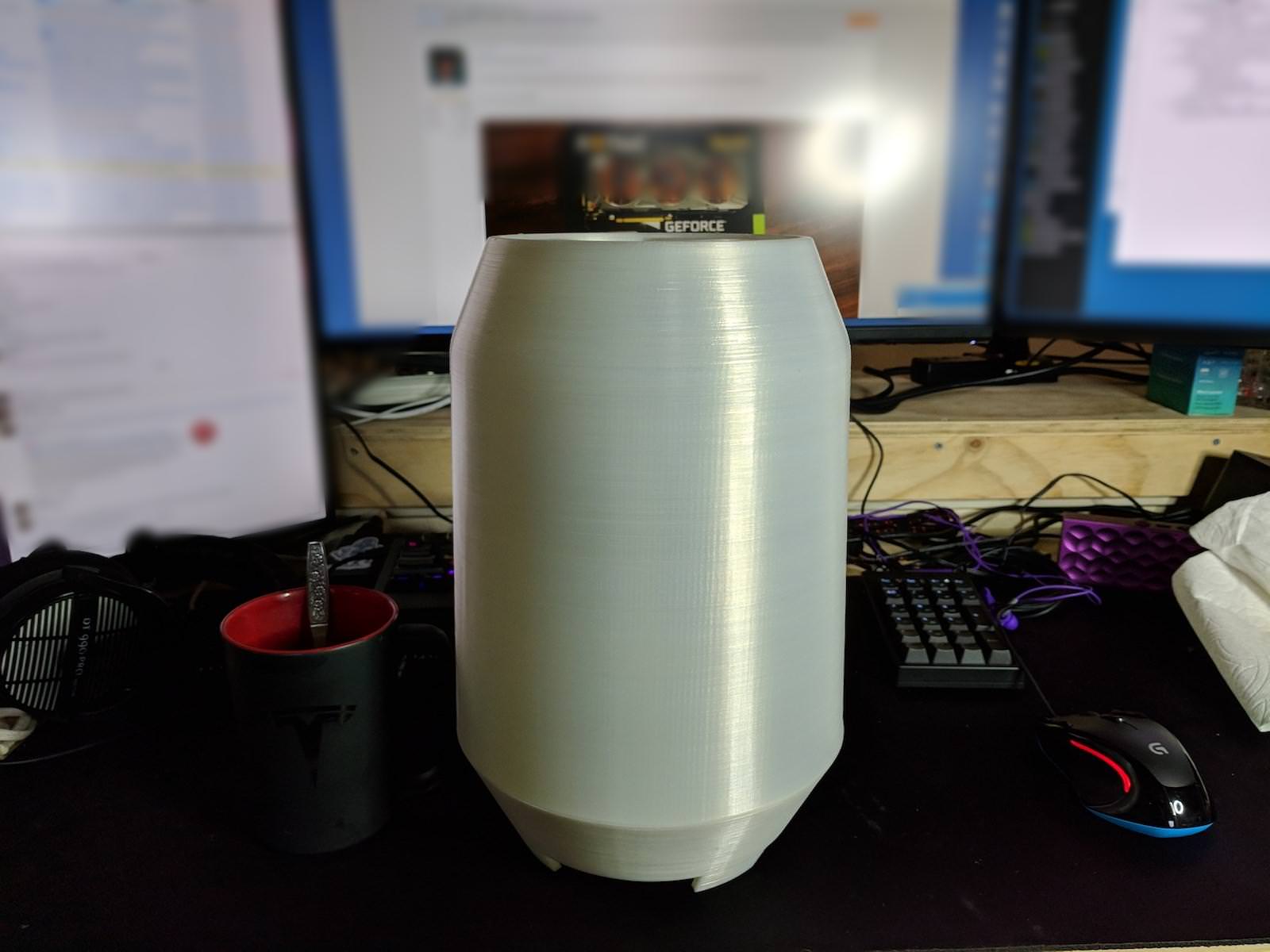

First off, I don't have a 3D printer and did not design or create this case! I was lurking eBay and came across this 3D Printed mini-ITX case that someone created as a project for his HTPC at home. His friends said, "Hey, that's pretty neat, you should make a few more and sell them online!" Here is the eBay listing:

https://www.ebay.com/itm/NEW-Mini-I...e-Custom-Designed-Rugged-Stylish/112738026600

(In case that link goes bad in the future, here is a backup album of all the seller's original photos from the listing: https://imgur.com/a/tXOkG)

Upon receiving the case I pinged the guy asking for more details about the build, asked if he had a build log somewhere (he did not). He only sent me a few more pictures of the case which aren't in the eBay listing. I let him know I'd do a build log online and give him the credit for the case.

For $99 I couldn't pass it up and bought it with the justification that, "It's about time I built a SFF computer."

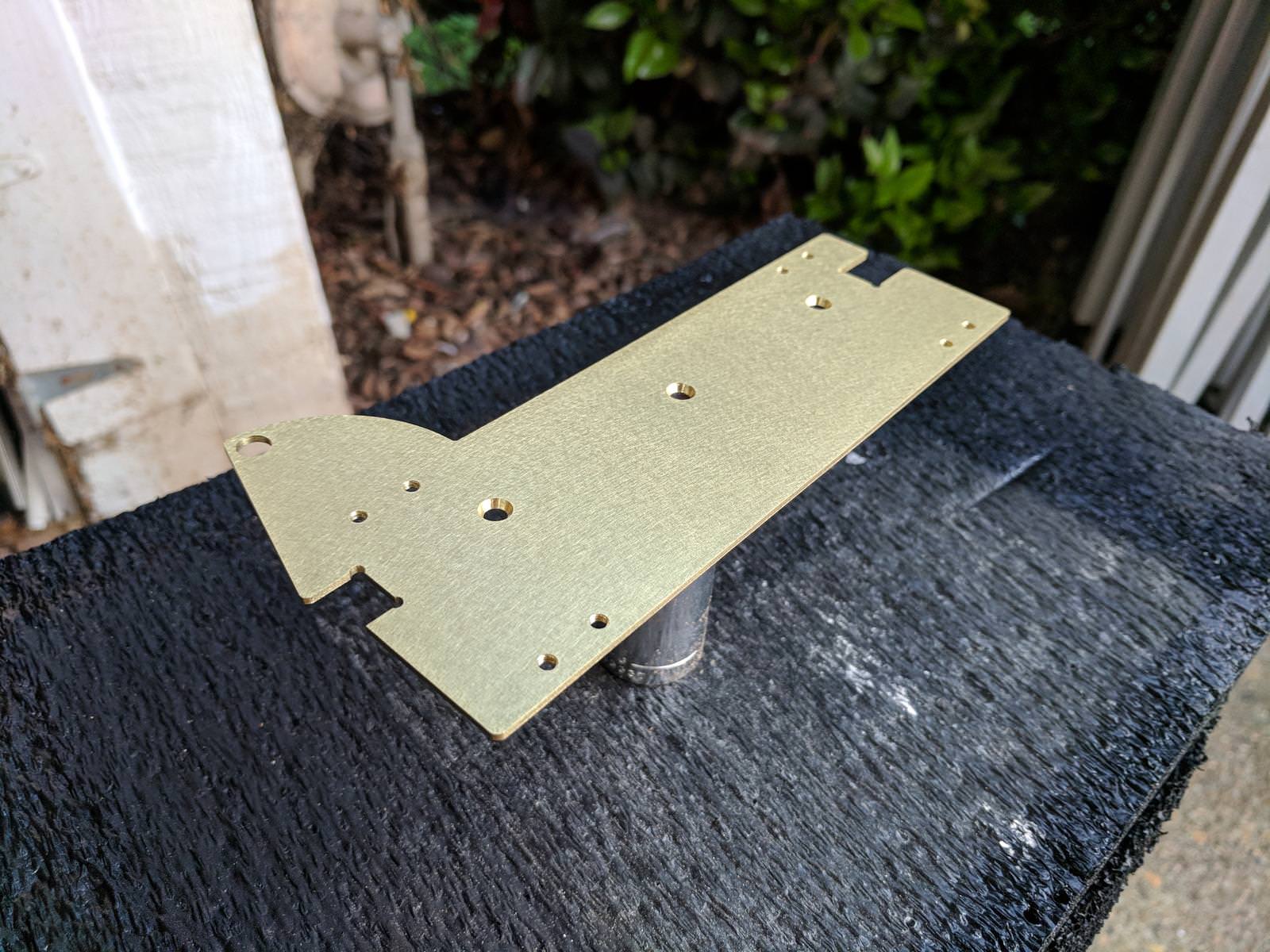

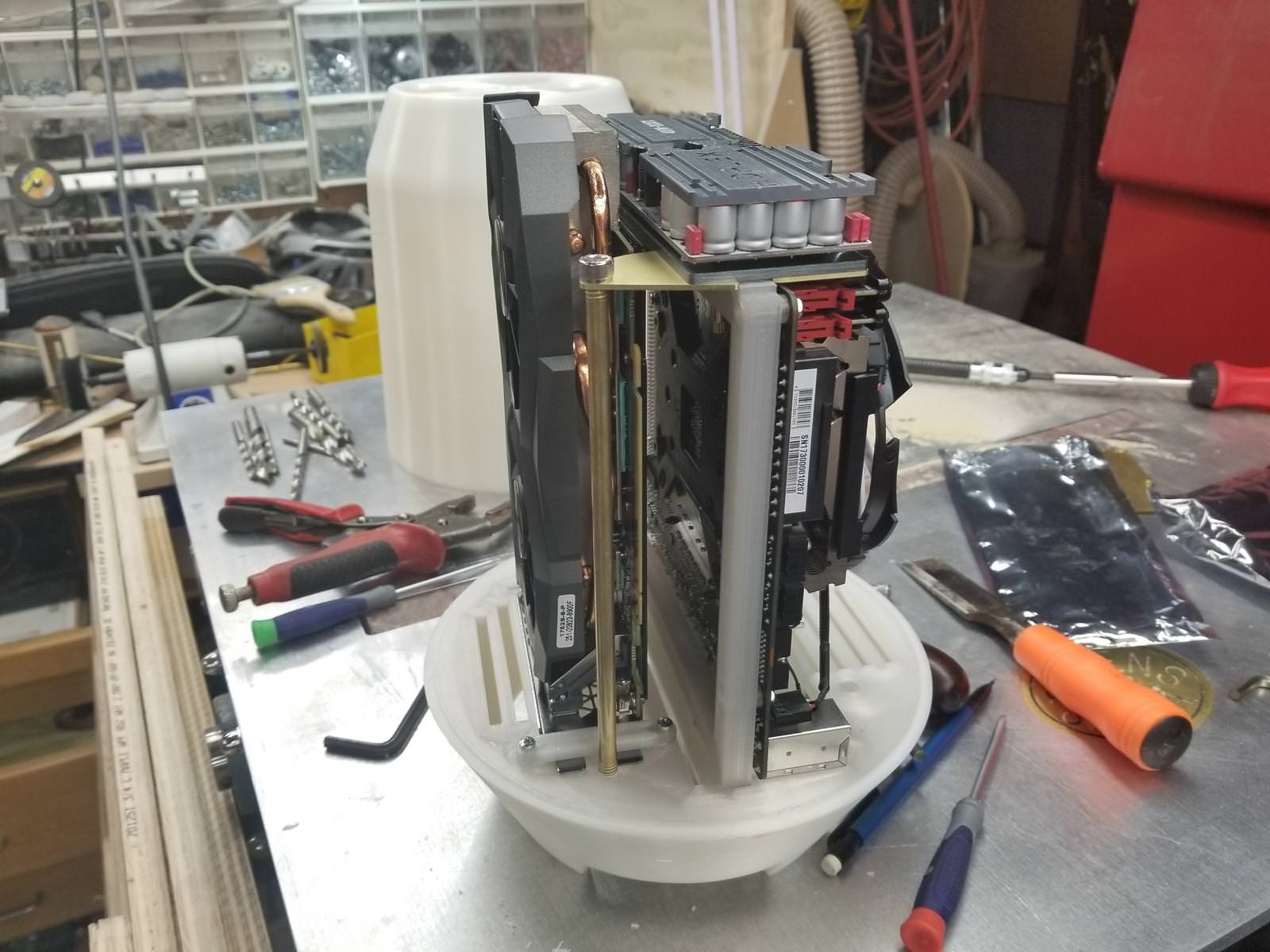

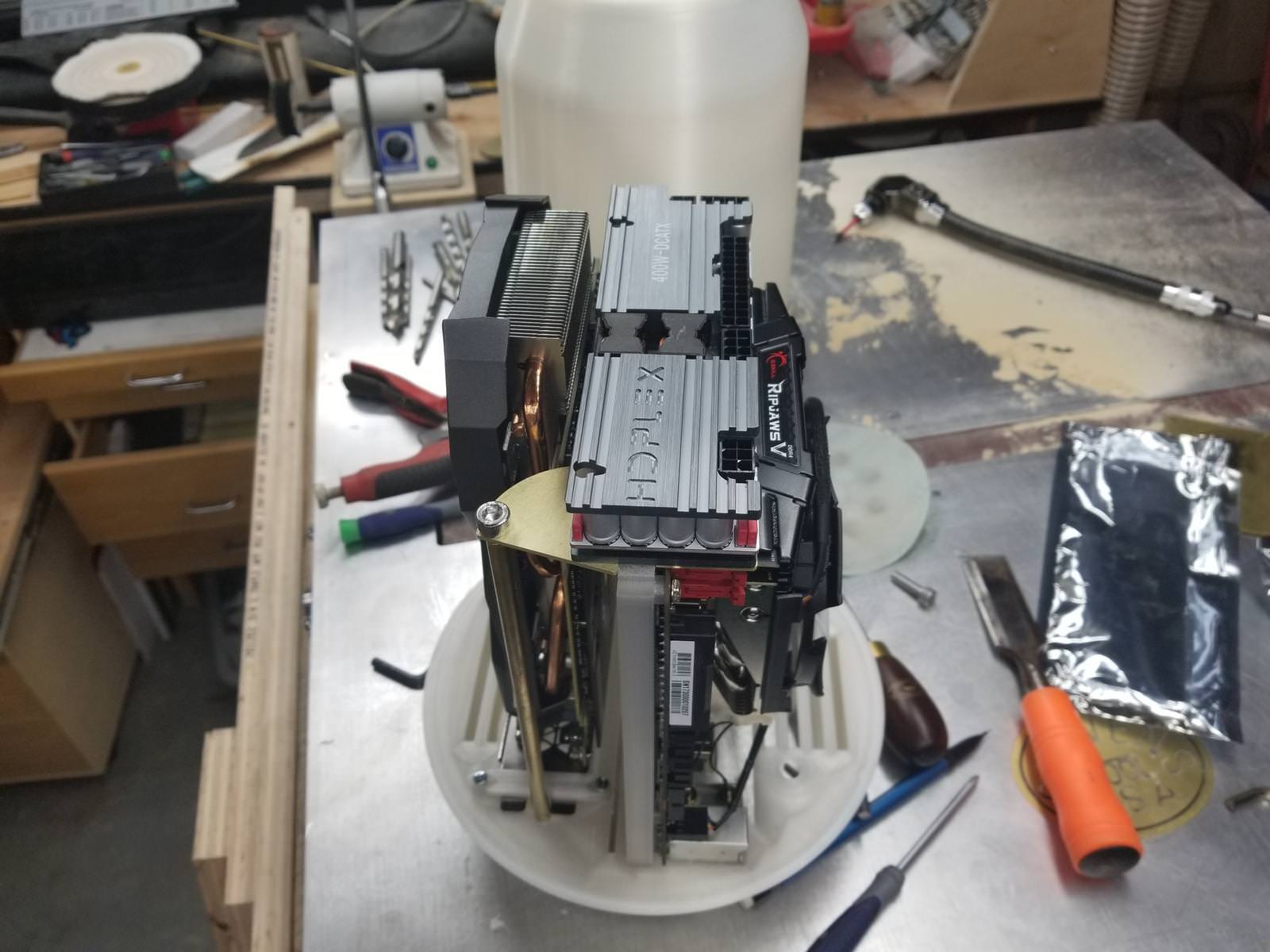

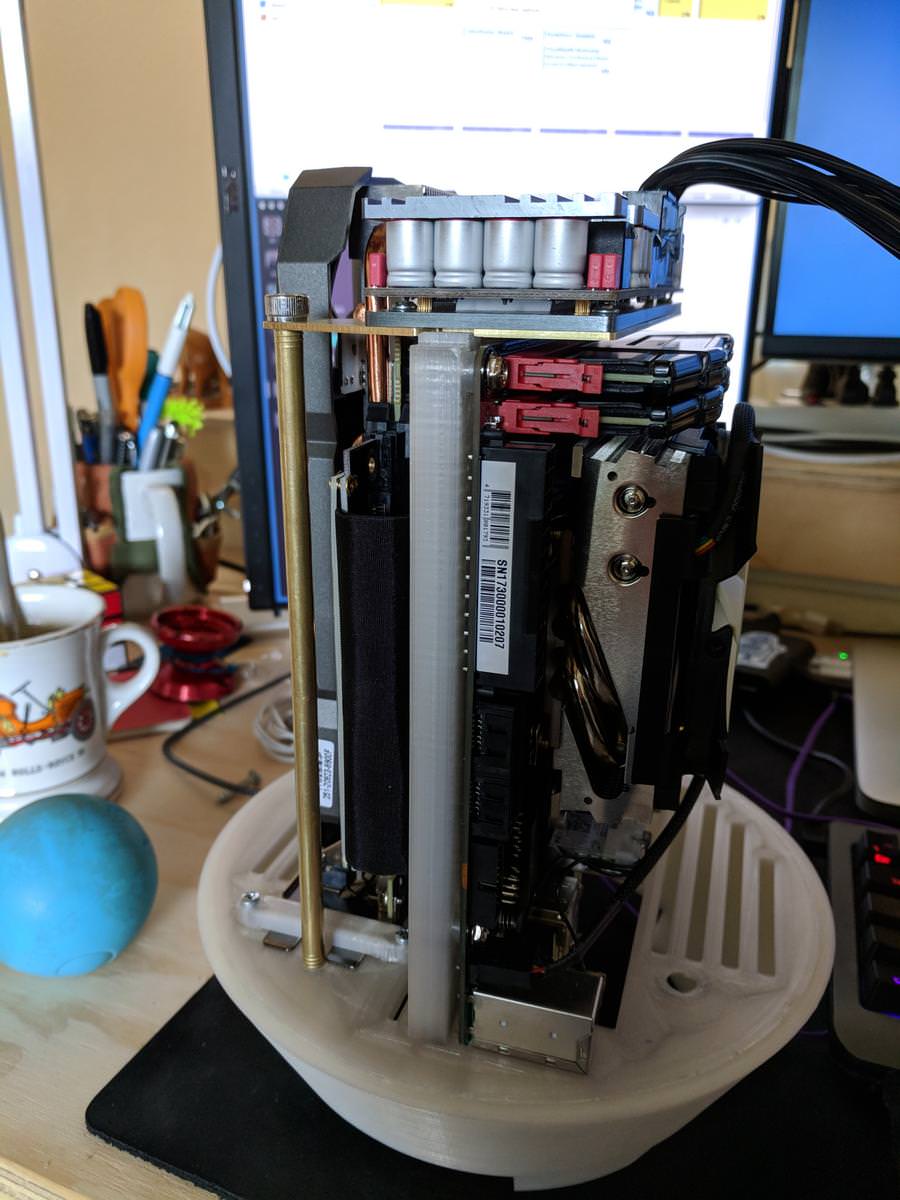

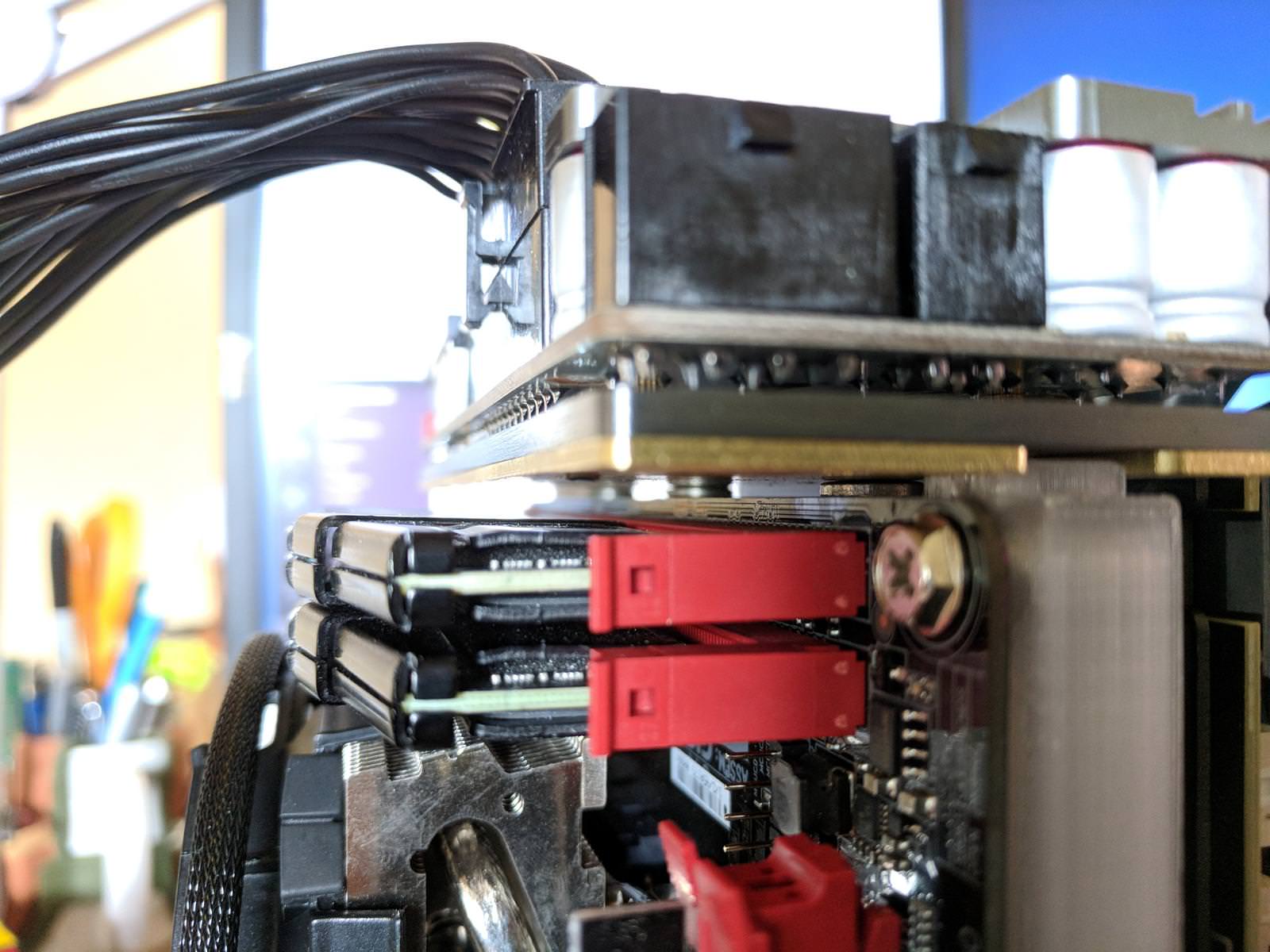

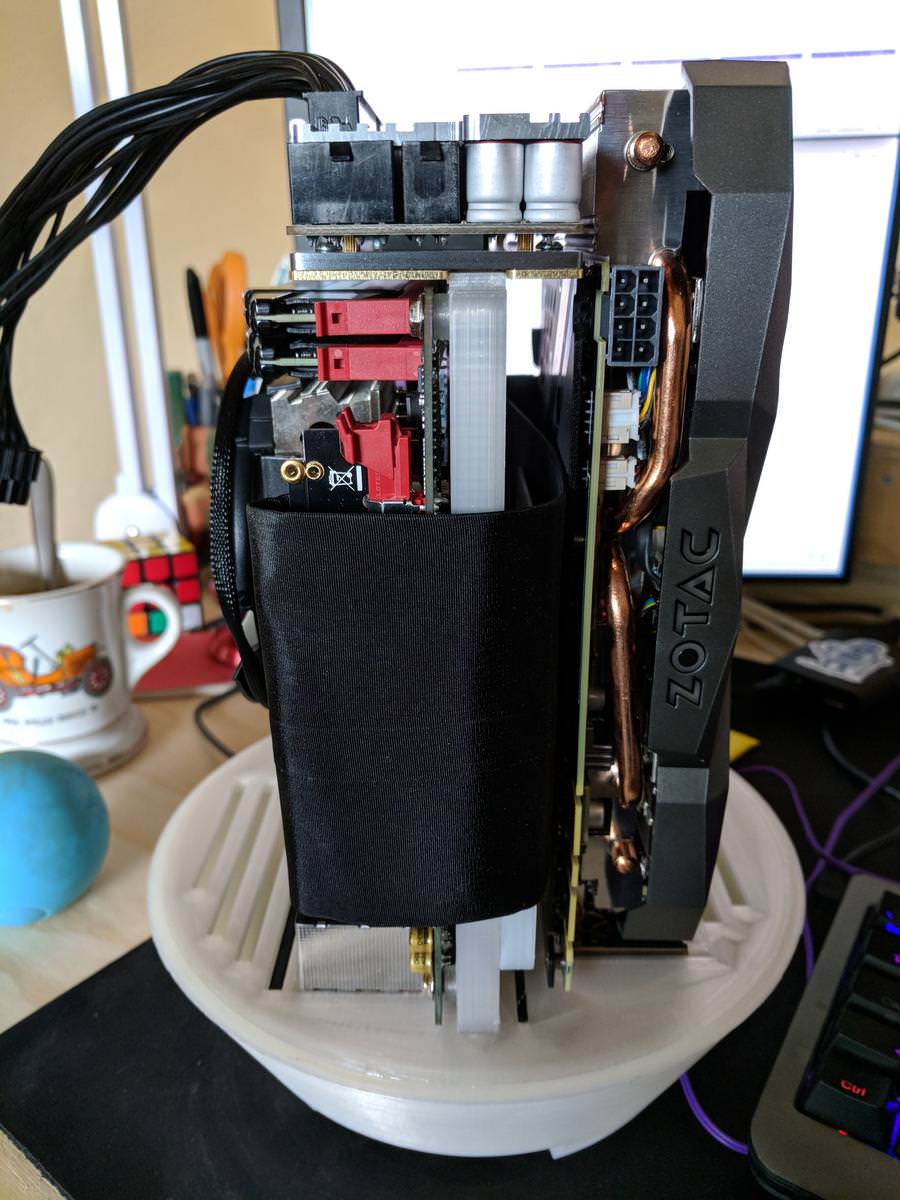

For rather obvious reasons, I dub this build: The TrashCan

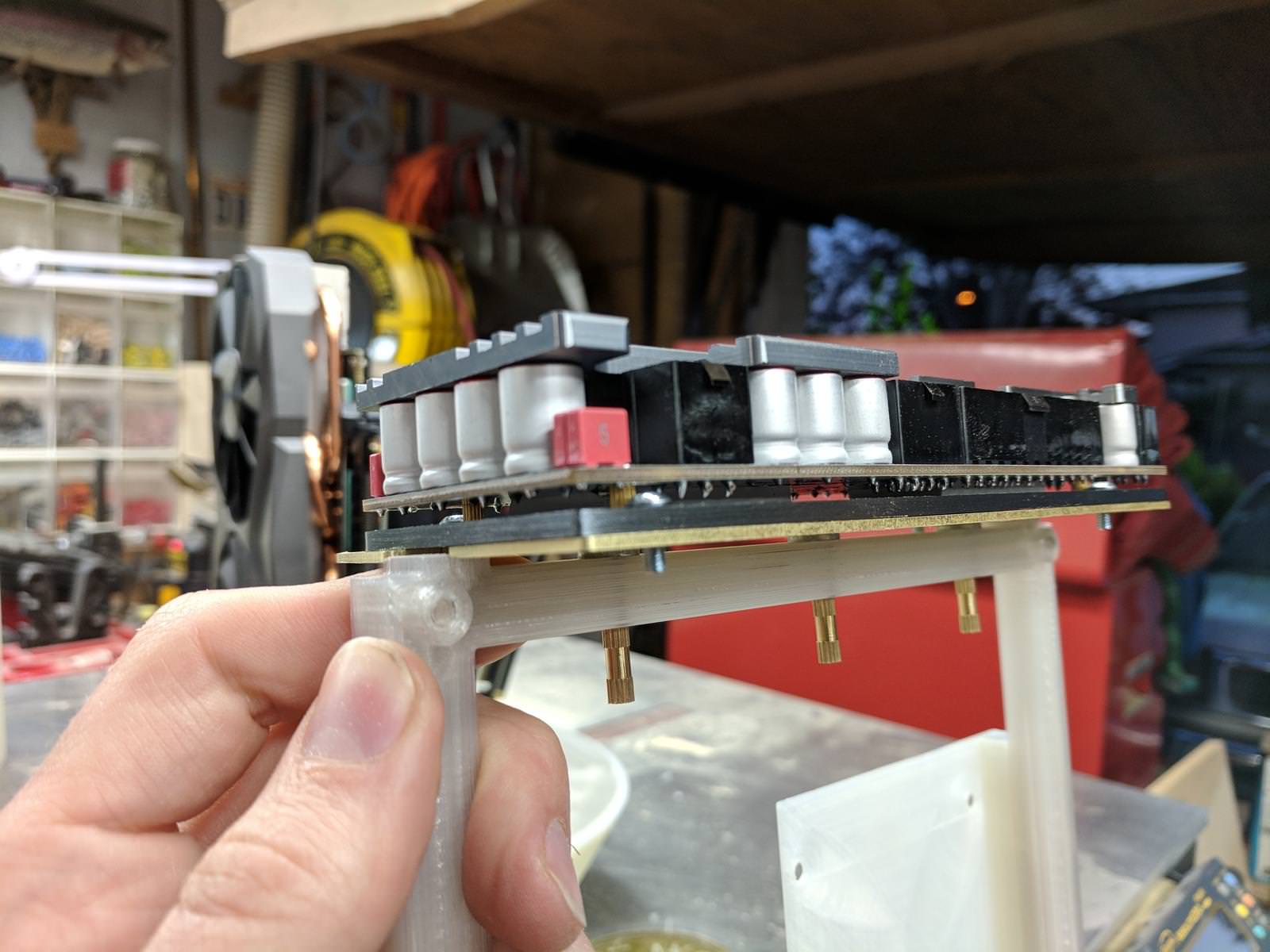

Parts list:

Some of these parts I already had on hand, all others have been ordered or I need to pickup at the local comp shop. I also plan to build a control box for this thing.

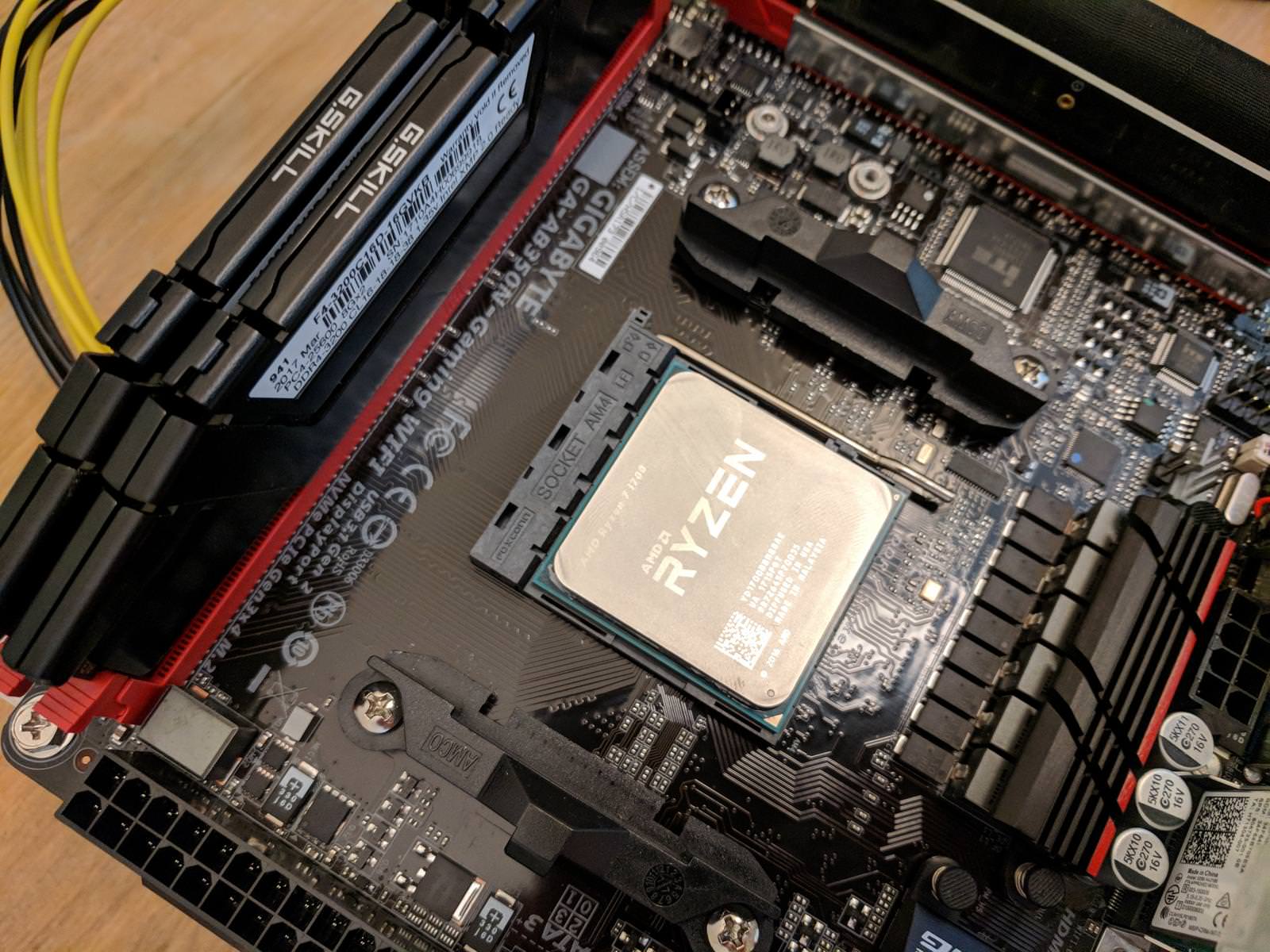

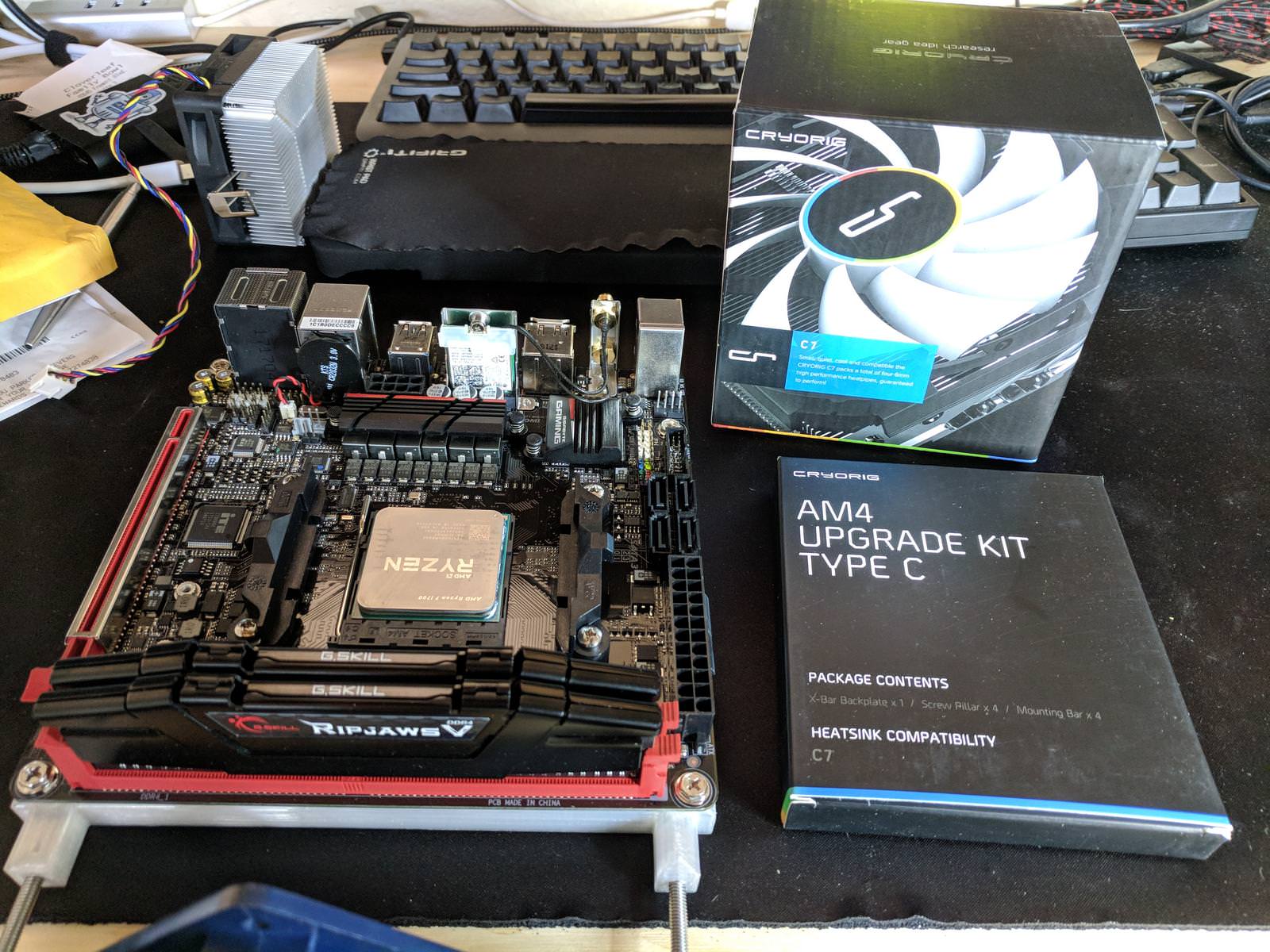

CPU - Ryzen 1700

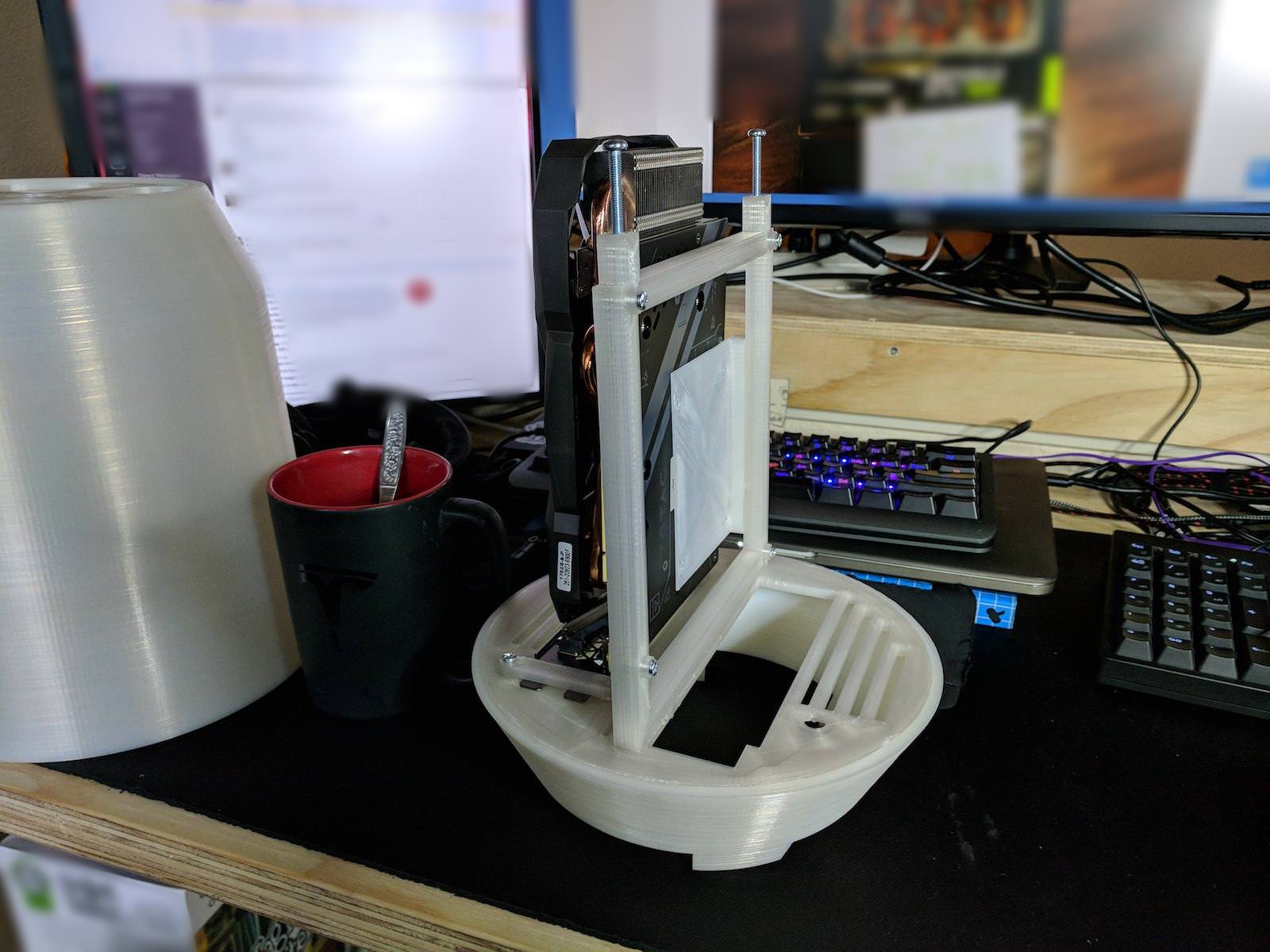

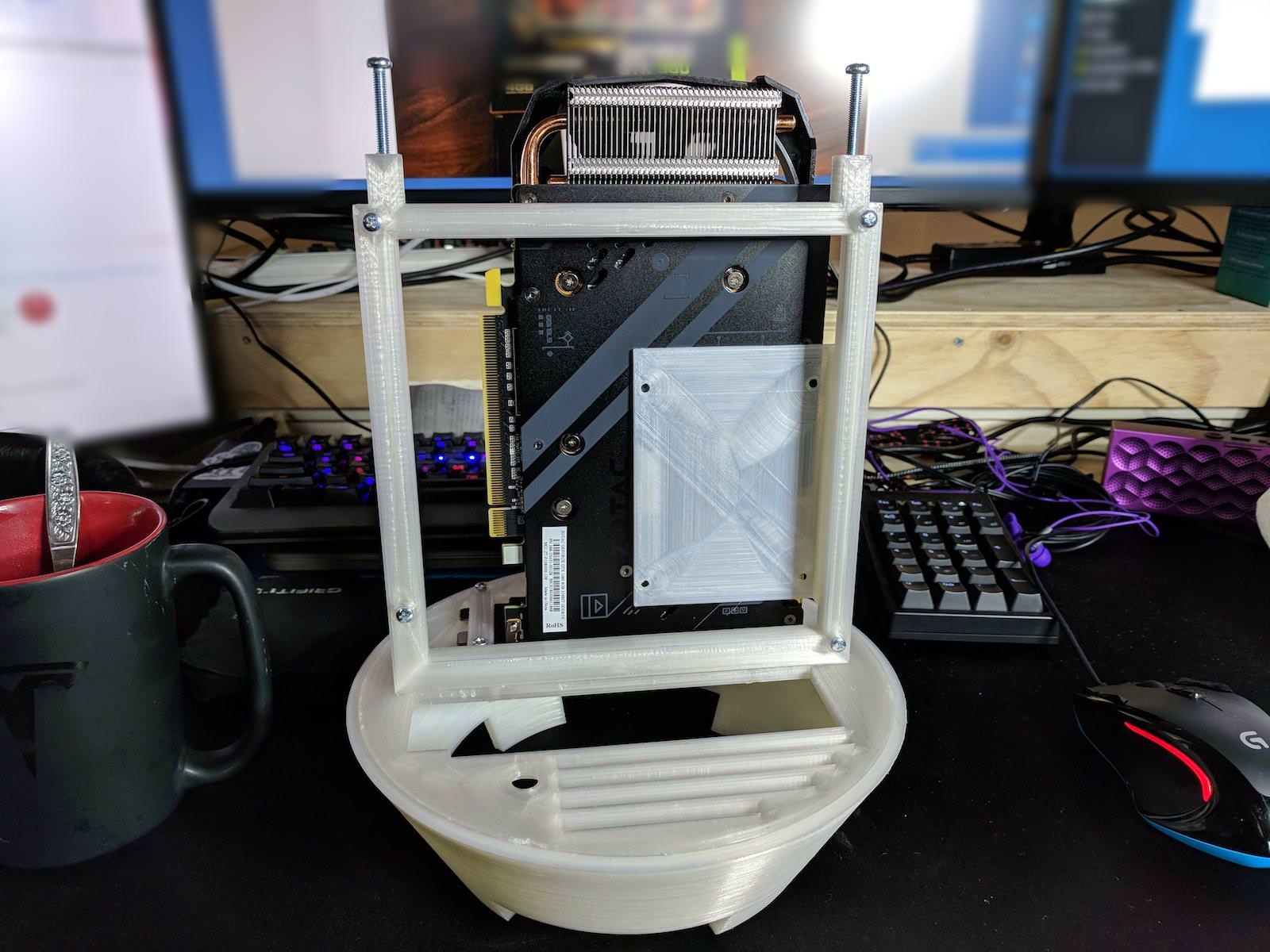

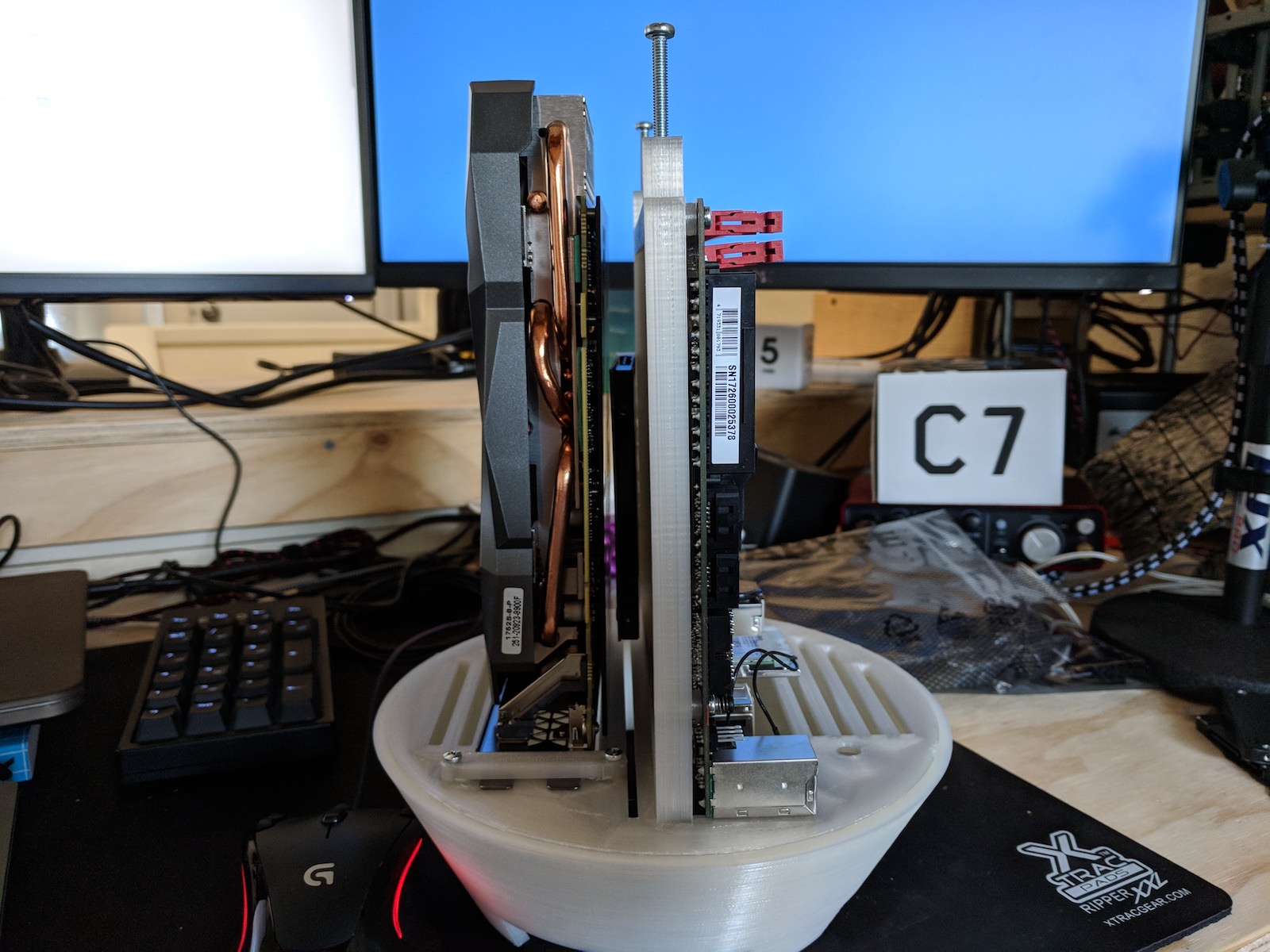

GPU - Zotac GTX 1080 Mini

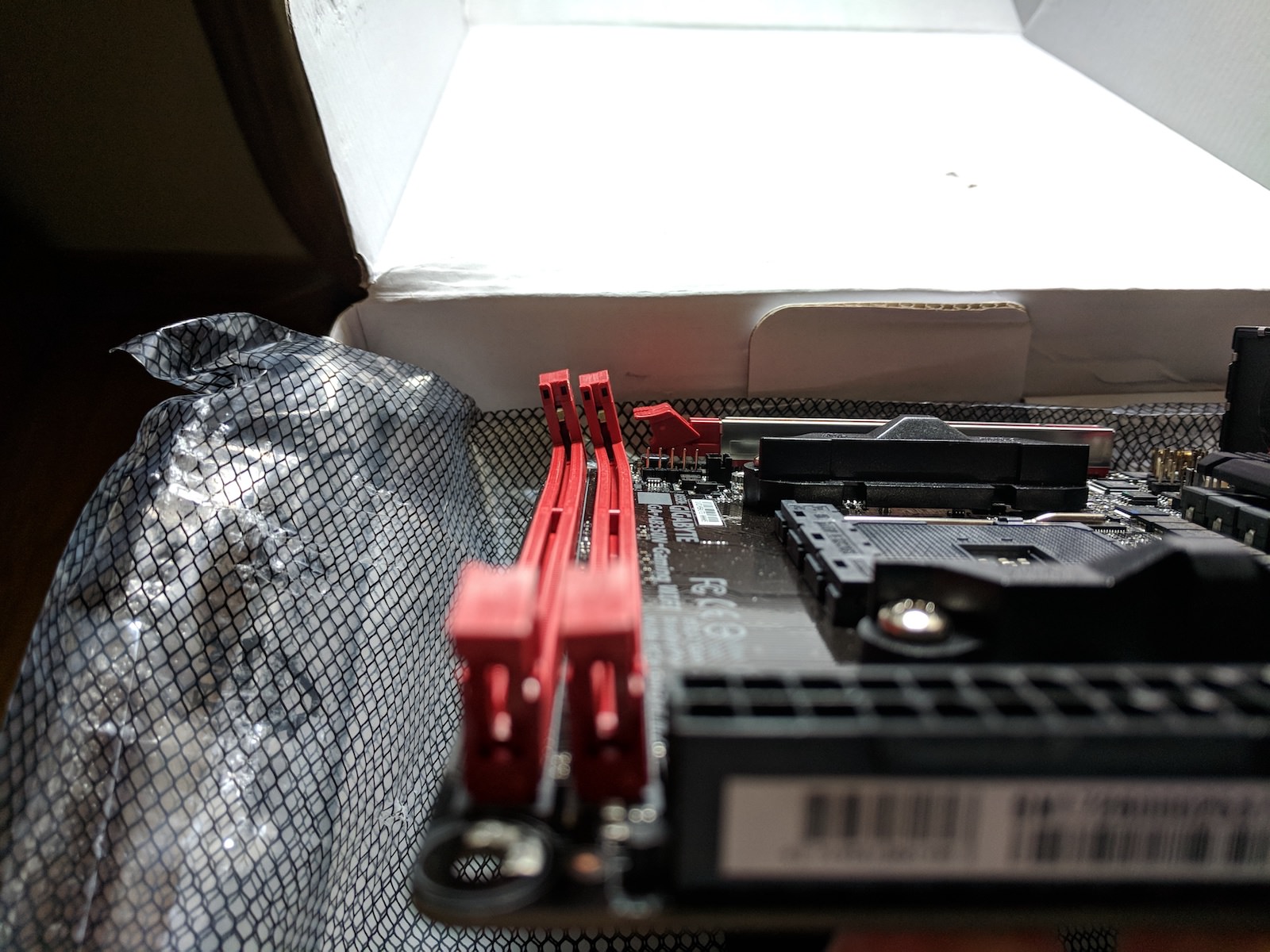

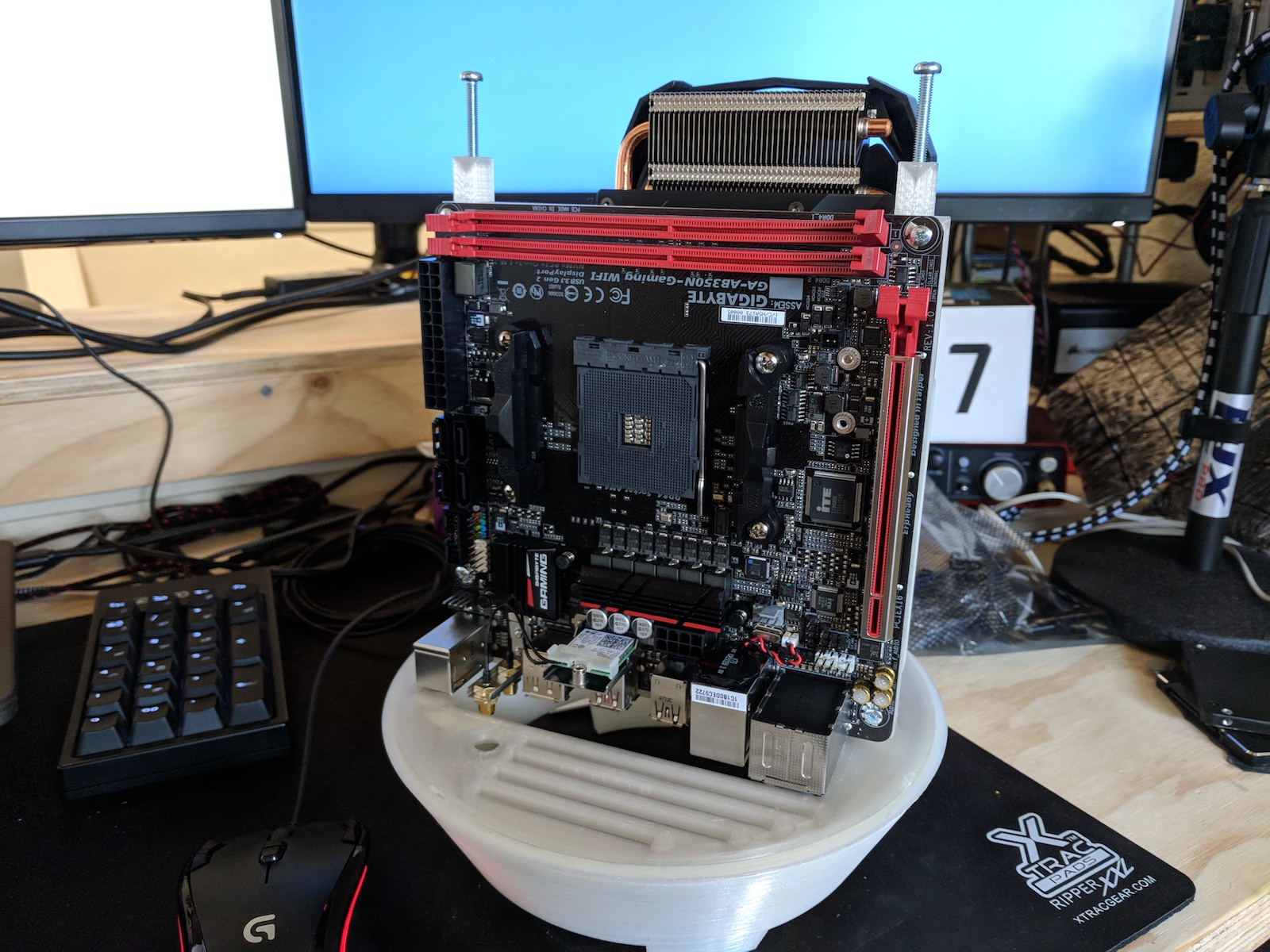

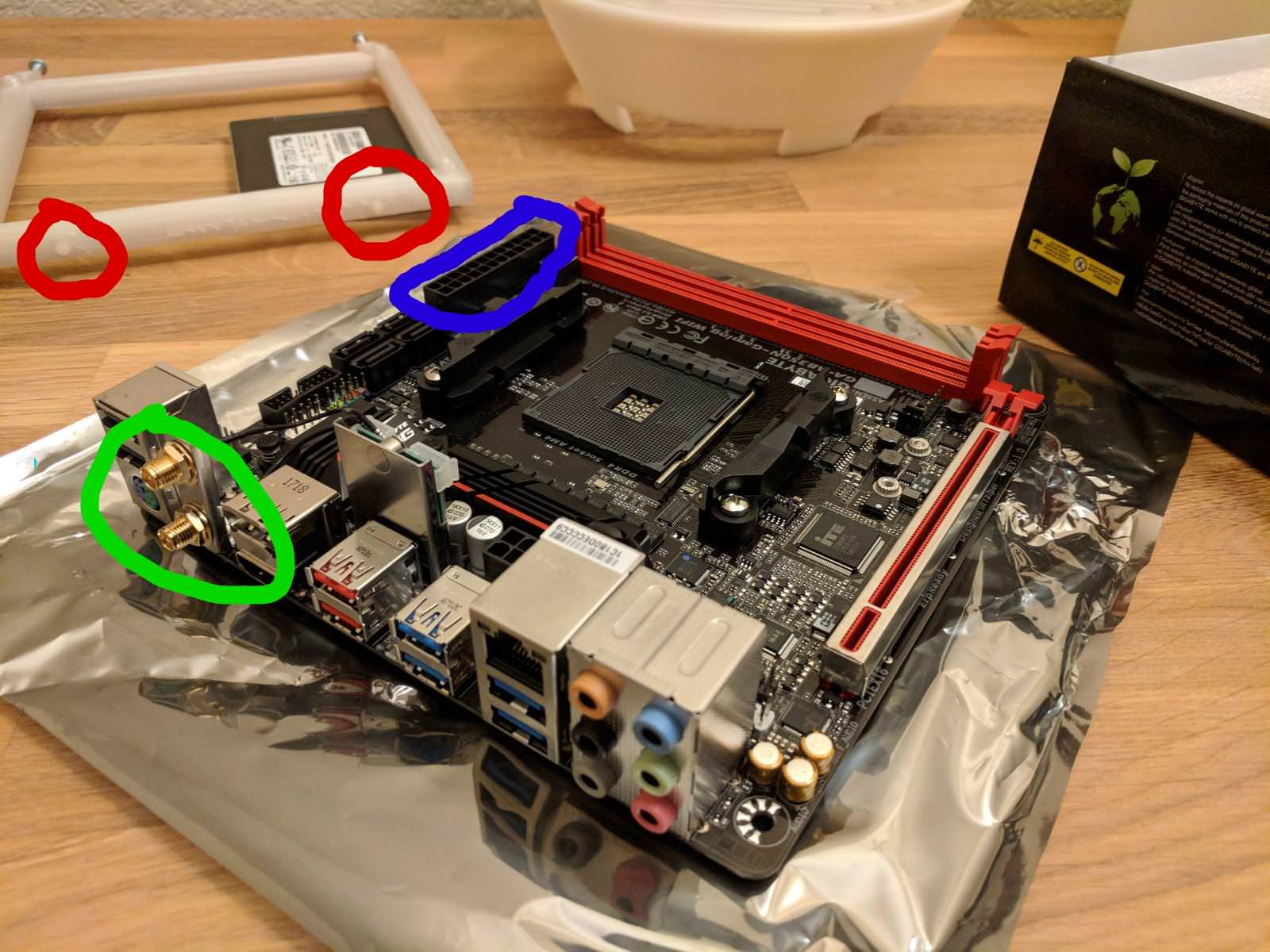

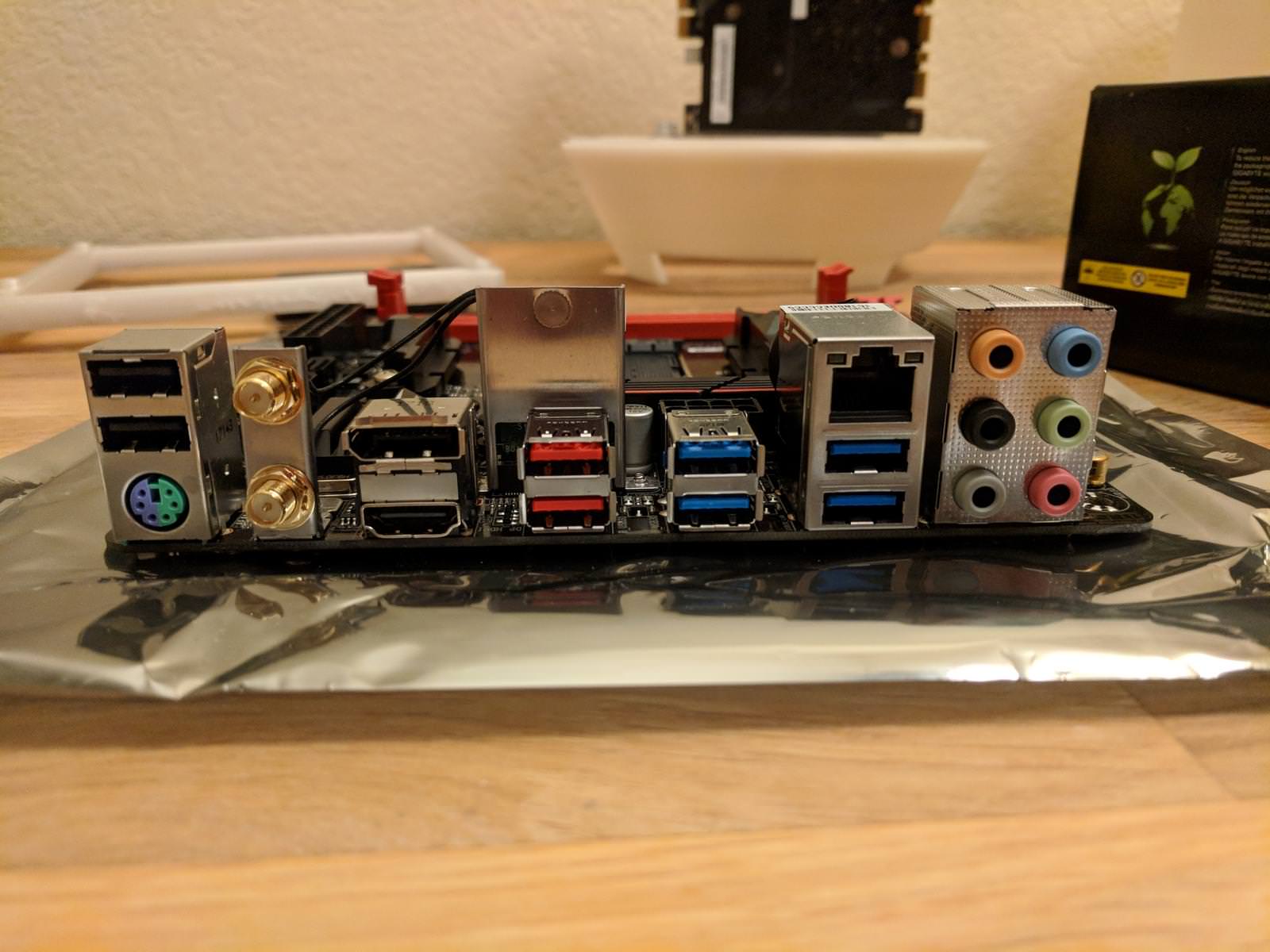

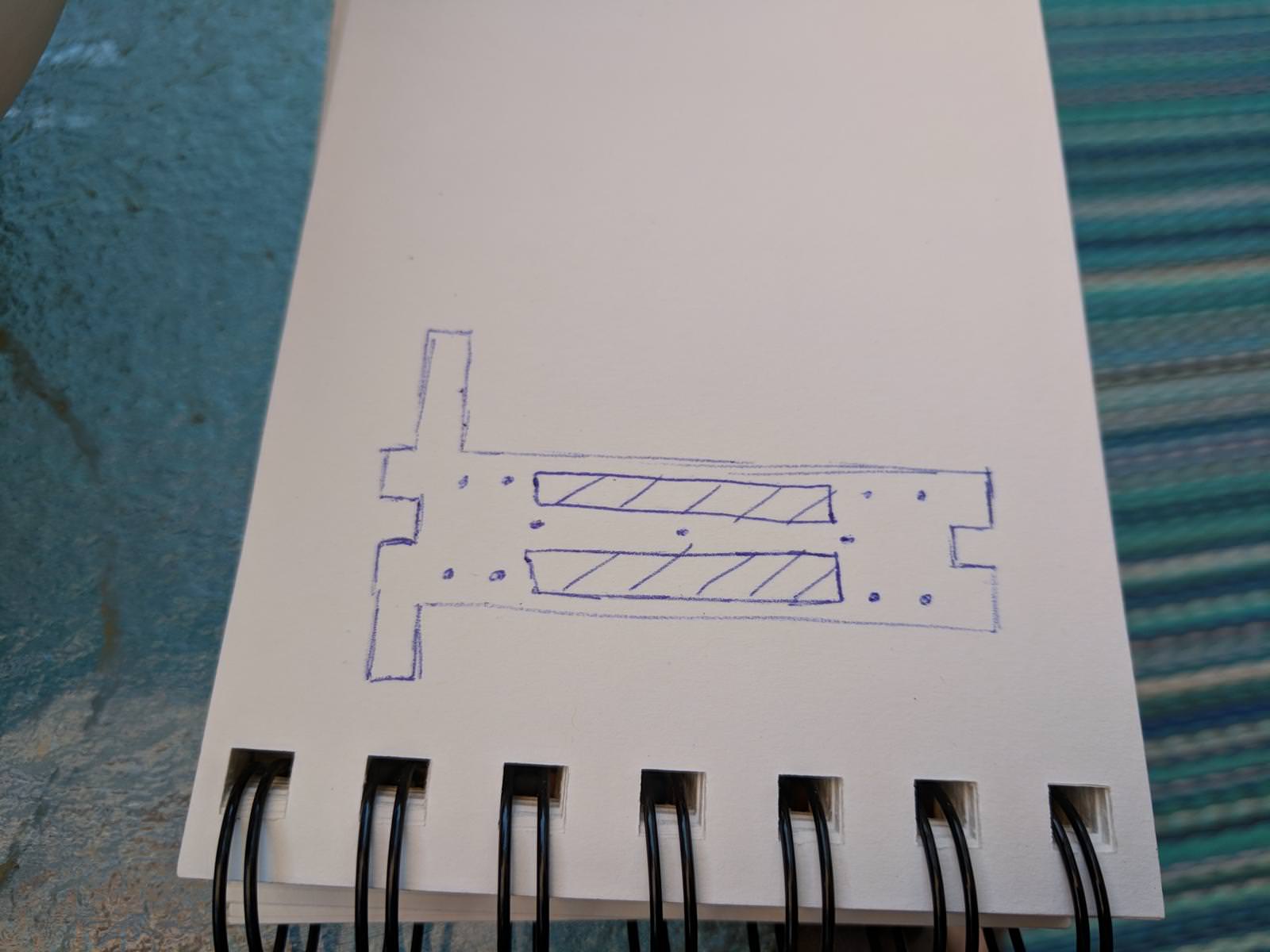

MB - Gigabyte AB350 Gaming Mini ITX

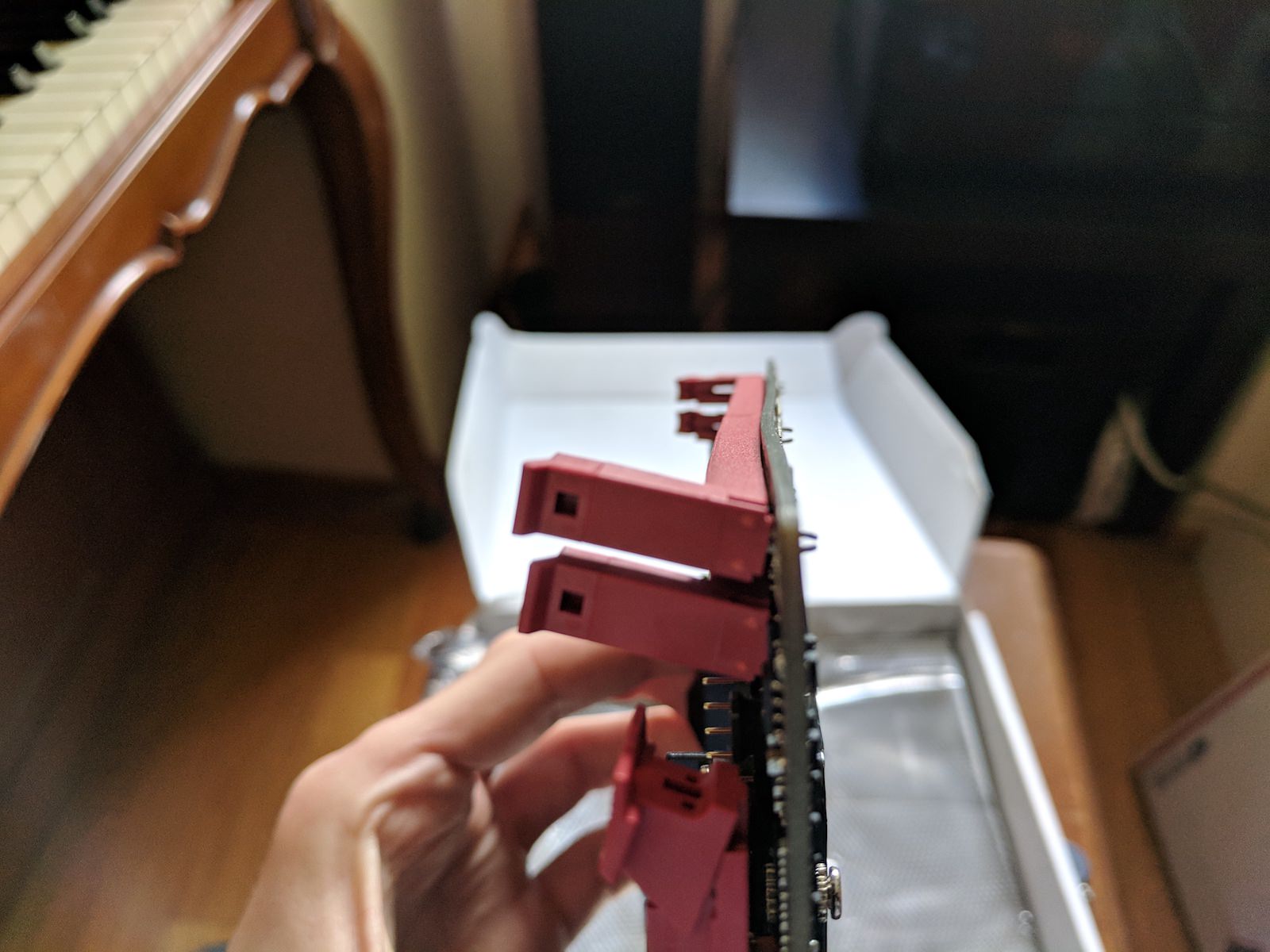

RAM - G.Skill DDR4 16GB 3200Mhz

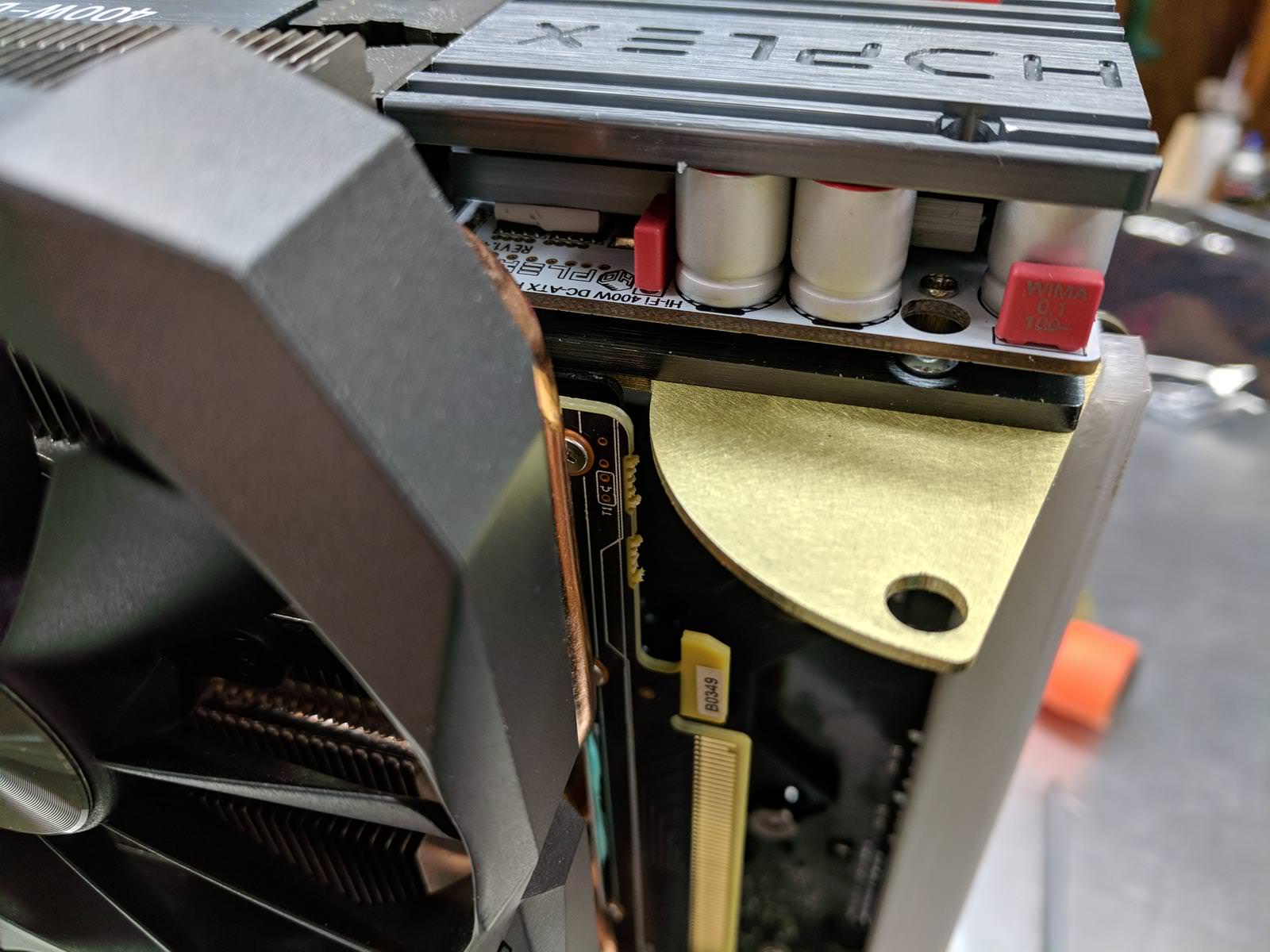

PSU - HDPlex 400W + Dell 330W

SSD - Samsung NVMe 250GB M.2 + Crucial MX500GB SATA SSD

Cooling:

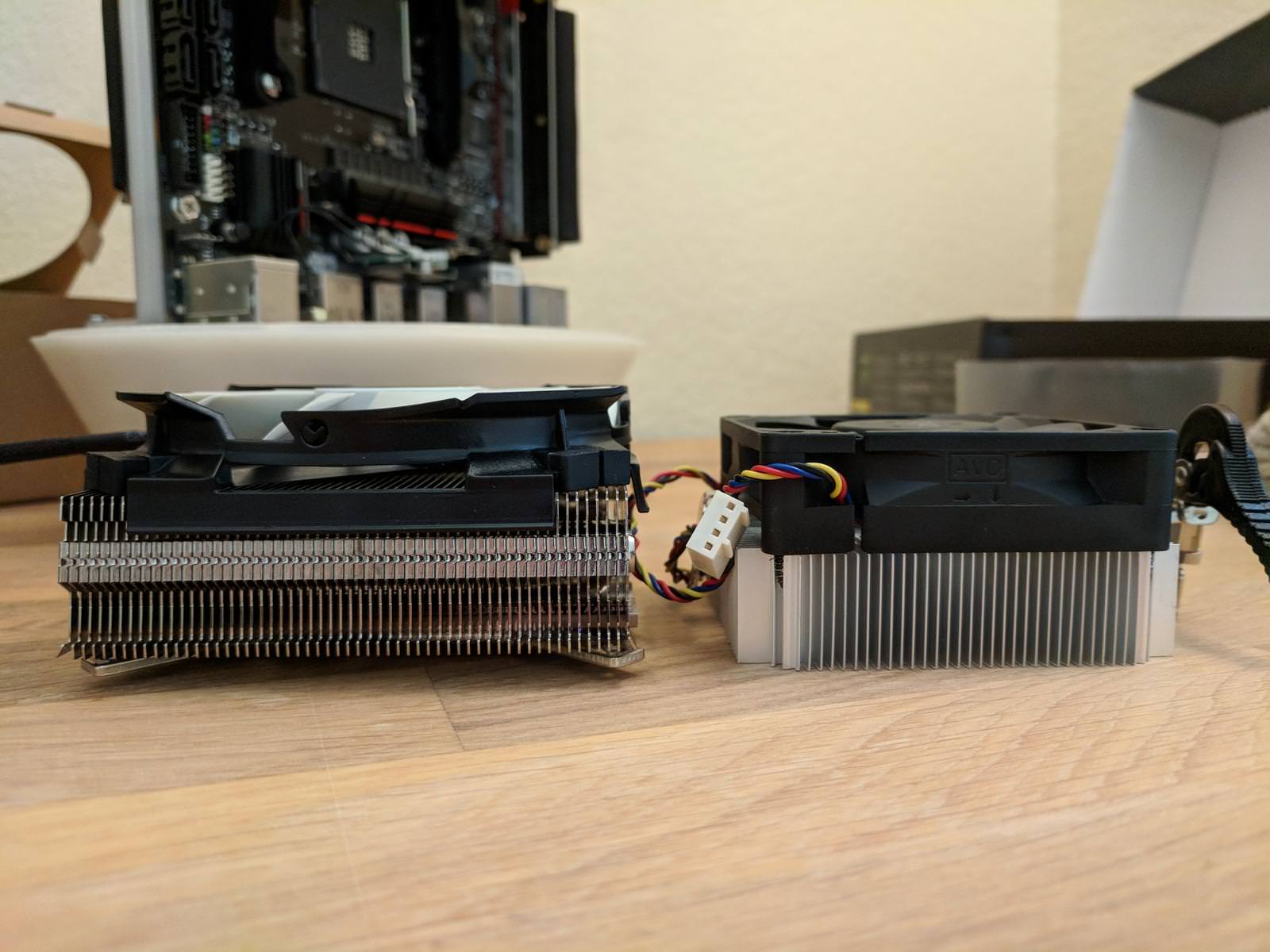

GPU = Stock

CPU = Cryorig C7 Low Profile

Top Exhaust Fan = 120mm (140mm??) ~ TBD ~

External Control box:

Temp Sensors

On/Off switch for computer

On/Off switch for AC-DC power

Fan Controller?

~~~~~~

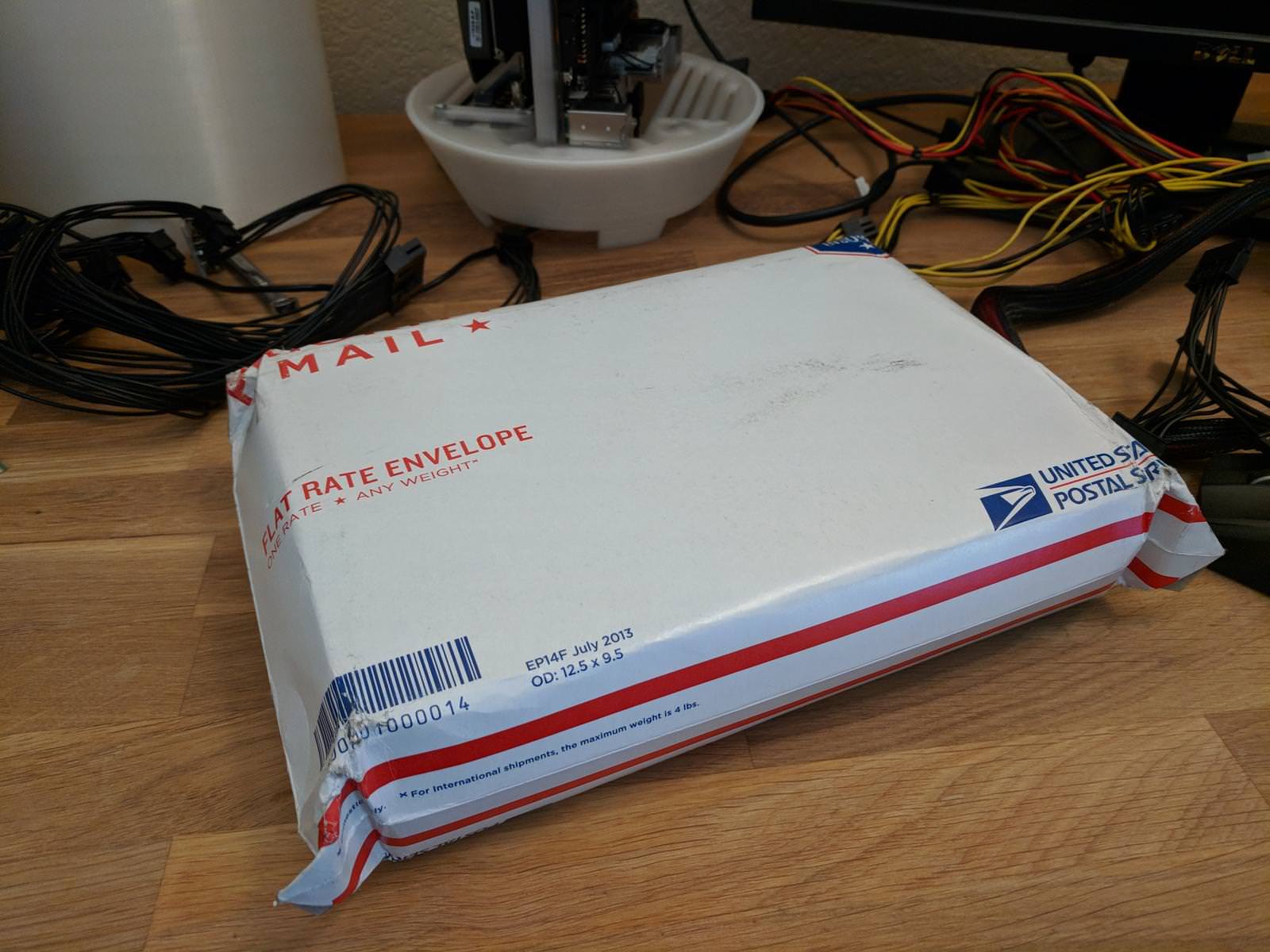

Overall, this is going to be a tricky case to cram all this hardware in. Obviously, a dell brick is not going to fit in there but I've got a plan for that. More pics are coming as I've been working on this all week already, just been late to posting online. Stay tuned!!

~smee

I haven't done a build log in YEARS, my professional life has gotten in the way of documenting creativity even though I tend to get the build-itch once a year and part-out an old system to make room for a new one. This year I got the SSF itch. Two years ago I did a SFF build using the NCase M1 (V3) which was friggin sweet, however, it wasn't much of a challenge in terms of cramming hardware in there... and I like a good challenge.

A little about me: I'm in my mid-twenties, I work from home as a Cloud Engineer (AWS) for a local tech company, I am a musician and love being creative in general. I was born and raised here in the Bay Area of CA and grew up in my Father's wood shop. I mention that because you'll see some of his handy work here later.

Down to business:

First off, I don't have a 3D printer and did not design or create this case! I was lurking eBay and came across this 3D Printed mini-ITX case that someone created as a project for his HTPC at home. His friends said, "Hey, that's pretty neat, you should make a few more and sell them online!" Here is the eBay listing:

https://www.ebay.com/itm/NEW-Mini-I...e-Custom-Designed-Rugged-Stylish/112738026600

(In case that link goes bad in the future, here is a backup album of all the seller's original photos from the listing: https://imgur.com/a/tXOkG)

Upon receiving the case I pinged the guy asking for more details about the build, asked if he had a build log somewhere (he did not). He only sent me a few more pictures of the case which aren't in the eBay listing. I let him know I'd do a build log online and give him the credit for the case.

For $99 I couldn't pass it up and bought it with the justification that, "It's about time I built a SFF computer."

For rather obvious reasons, I dub this build: The TrashCan

Parts list:

Some of these parts I already had on hand, all others have been ordered or I need to pickup at the local comp shop. I also plan to build a control box for this thing.

CPU - Ryzen 1700

GPU - Zotac GTX 1080 Mini

MB - Gigabyte AB350 Gaming Mini ITX

RAM - G.Skill DDR4 16GB 3200Mhz

PSU - HDPlex 400W + Dell 330W

SSD - Samsung NVMe 250GB M.2 + Crucial MX500GB SATA SSD

Cooling:

GPU = Stock

CPU = Cryorig C7 Low Profile

Top Exhaust Fan = 120mm (140mm??) ~ TBD ~

External Control box:

Temp Sensors

On/Off switch for computer

On/Off switch for AC-DC power

Fan Controller?

~~~~~~

Overall, this is going to be a tricky case to cram all this hardware in. Obviously, a dell brick is not going to fit in there but I've got a plan for that. More pics are coming as I've been working on this all week already, just been late to posting online. Stay tuned!!

~smee

As an eBay Associate, HardForum may earn from qualifying purchases.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)