Peter2k

Limp Gawd

- Joined

- Apr 25, 2016

- Messages

- 309

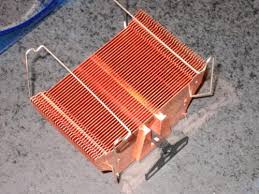

How safe/unsafe is it to place a water block directly on the core?

mmm

Well first you need to take care of the difference in height

that's probably the worst

the DIE reminded me of my AthlonXP and Duron days

should be fine if handled with care

if you get the height right

also a custom cooler would probably be better for that

AiO use a pump on the CPU block

adding weight, as well as strain from the hoses

using a custom loop you remove the weight of the pump and you can make the hose or pipes fit to you're case

removing any pull from them

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)