ccityinstaller

Supreme [H]ardness

- Joined

- Feb 23, 2007

- Messages

- 4,236

Hey guys,

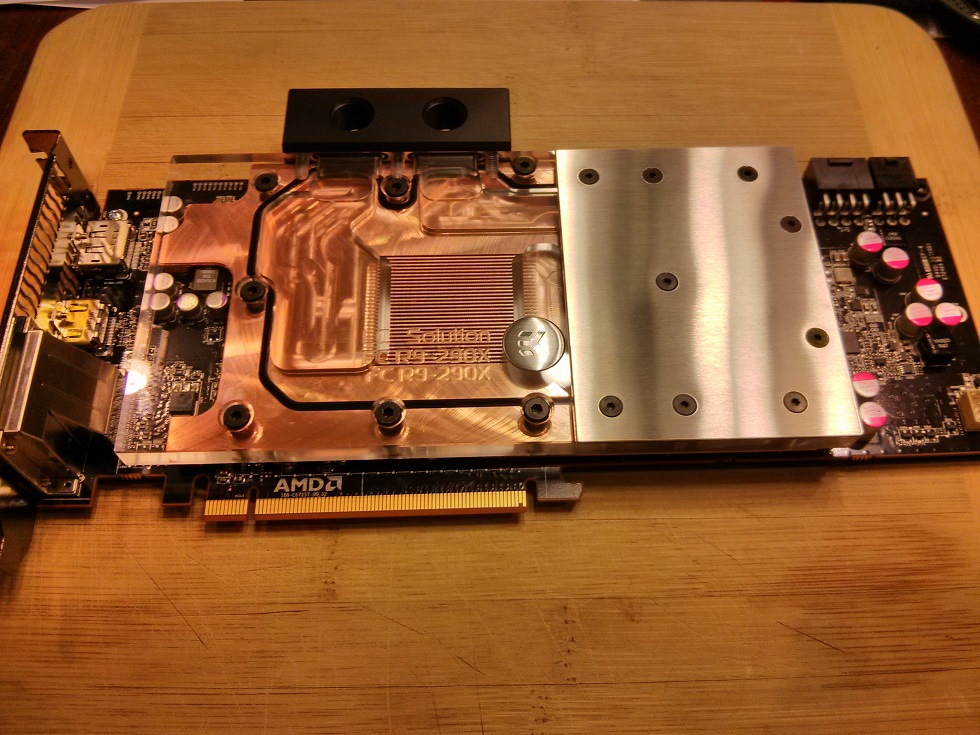

After getting shafted by Sapphire and NE in regards to the BF4 bundle, I decided that I might as well go ahead and open my card and GPU block up..Well, as many remember, EK royally fucked the community over a few years ago with their plating issues...I talked myself into buying one of their blocks since it was all copper (thus no flaking) and was a good bit cheaper then the only other choice, the Koolance...I was initially in a hurry for it to get here, and the Koolance wasn't in stock with any East Coast E-tailers, so I ordered the EK block from Frozen CPU....

Here is what I found when I opened the box..I apologize for the quality of the pictures, but I did not want to to crack EK's seal (least they accuse me of purposefully ruining a $110 GPU block) and it was encased in a pretty thick plastic bag..

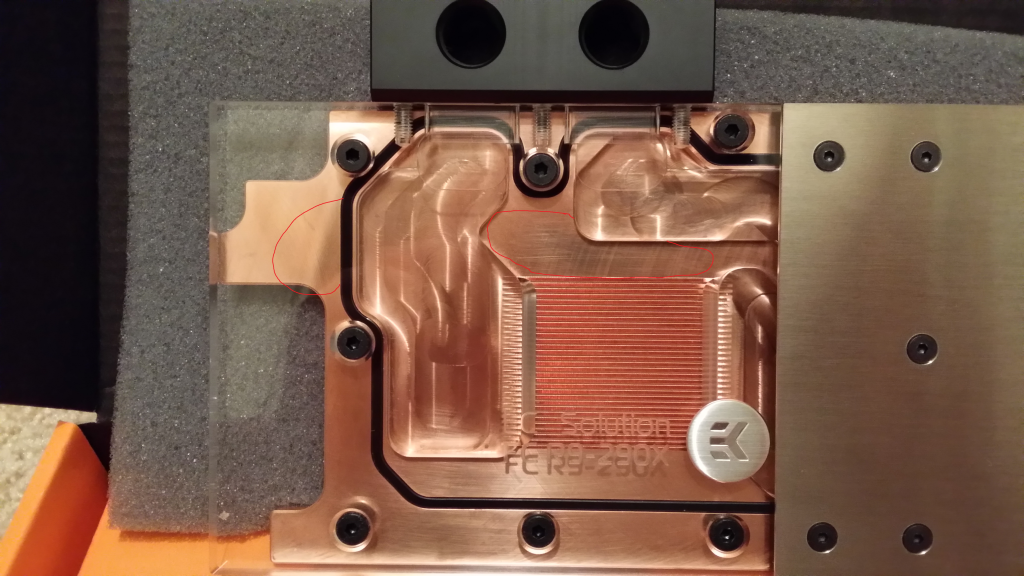

The picture below is the area that directly contacts the GPU die..Looks like Wolverine was sharpening his claws on it

..

..

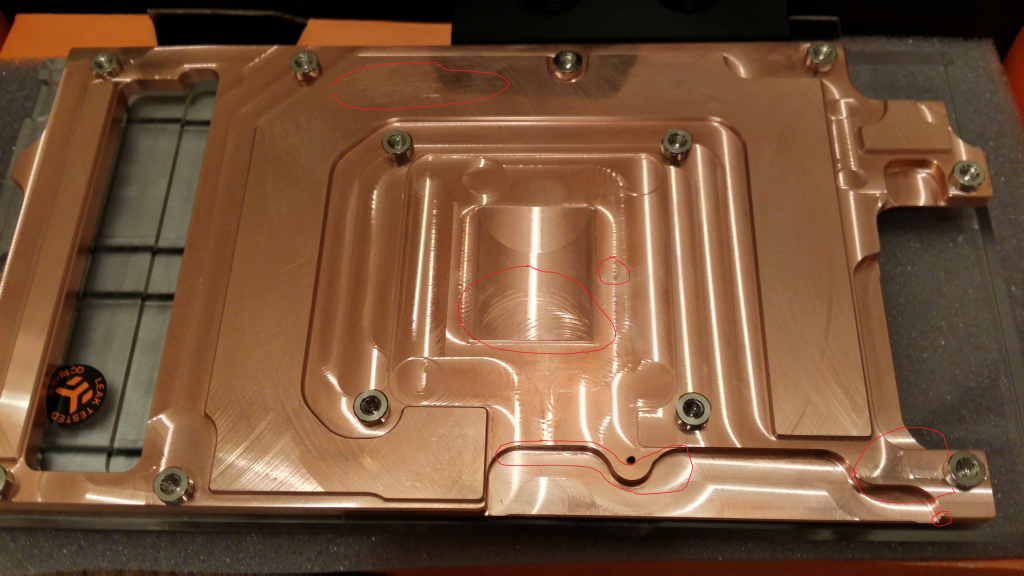

Here you see the poor machining and "stains" on the block:

Here you see the crappy machine work/staining in the area that will be visible:

Poor Machining/Deep Scratches on the Memory area:

Larger Shot of the Overall Piss Poor Machining/Stains:

Now, FrozenCPU had a sticker on the OUTSIDE of the box saying "no returns, make sure of fitment" which I assume is due to the fact that until last Friday, EK was the only company producing GPU Blocks for the 290/290X and they are very hard to keep in stock..

I am now showing you the results of EK being greedy and attempting to rush the machining on these blocks..My Uncle (Master Machinist ~45 years) was appalled at the work, and said that an apprentice could have done a better job...I am going to call FrozenCPU in the morning, and if they refuse to issue me a FULL REFUND, INCLUDING SHIPPING, I will be contacting VISA and filing a dispute. There is ZERO EXCUSE for allowing something like this to make it through their "QA Dept". The funny thing is that there is a QA sticker on the front of the block

...

...

After seeing the poor machining, there is no way I would EVER trust putting that block in system...I am paranoid as it it about leaks, and this does nothing but make that fear even worse..Do you guy's feel I am wrong for demanding a full return despite that bullshit sticker on the outside? How was I supposed to know the GPU block was going to look like someone took a dremel to it unless I opened it?

I suppose I should have known better then to buy an EK product, but I checked here, OC.net, and Xtreme, and didn't see anyone reporting any issues..

After getting shafted by Sapphire and NE in regards to the BF4 bundle, I decided that I might as well go ahead and open my card and GPU block up..Well, as many remember, EK royally fucked the community over a few years ago with their plating issues...I talked myself into buying one of their blocks since it was all copper (thus no flaking) and was a good bit cheaper then the only other choice, the Koolance...I was initially in a hurry for it to get here, and the Koolance wasn't in stock with any East Coast E-tailers, so I ordered the EK block from Frozen CPU....

Here is what I found when I opened the box..I apologize for the quality of the pictures, but I did not want to to crack EK's seal (least they accuse me of purposefully ruining a $110 GPU block) and it was encased in a pretty thick plastic bag..

The picture below is the area that directly contacts the GPU die..Looks like Wolverine was sharpening his claws on it

Here you see the poor machining and "stains" on the block:

Here you see the crappy machine work/staining in the area that will be visible:

Poor Machining/Deep Scratches on the Memory area:

Larger Shot of the Overall Piss Poor Machining/Stains:

Now, FrozenCPU had a sticker on the OUTSIDE of the box saying "no returns, make sure of fitment" which I assume is due to the fact that until last Friday, EK was the only company producing GPU Blocks for the 290/290X and they are very hard to keep in stock..

I am now showing you the results of EK being greedy and attempting to rush the machining on these blocks..My Uncle (Master Machinist ~45 years) was appalled at the work, and said that an apprentice could have done a better job...I am going to call FrozenCPU in the morning, and if they refuse to issue me a FULL REFUND, INCLUDING SHIPPING, I will be contacting VISA and filing a dispute. There is ZERO EXCUSE for allowing something like this to make it through their "QA Dept". The funny thing is that there is a QA sticker on the front of the block

After seeing the poor machining, there is no way I would EVER trust putting that block in system...I am paranoid as it it about leaks, and this does nothing but make that fear even worse..Do you guy's feel I am wrong for demanding a full return despite that bullshit sticker on the outside? How was I supposed to know the GPU block was going to look like someone took a dremel to it unless I opened it?

I suppose I should have known better then to buy an EK product, but I checked here, OC.net, and Xtreme, and didn't see anyone reporting any issues..

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)