]FERMI 2 - CUSTOM Dual Stacker 832 - sli GTX480's[/COLOR]

You can visit my entire post on EVGA FORUM - http://www.evga.com/forums/tm.aspx?high=&m=602083&mpage=1#602083

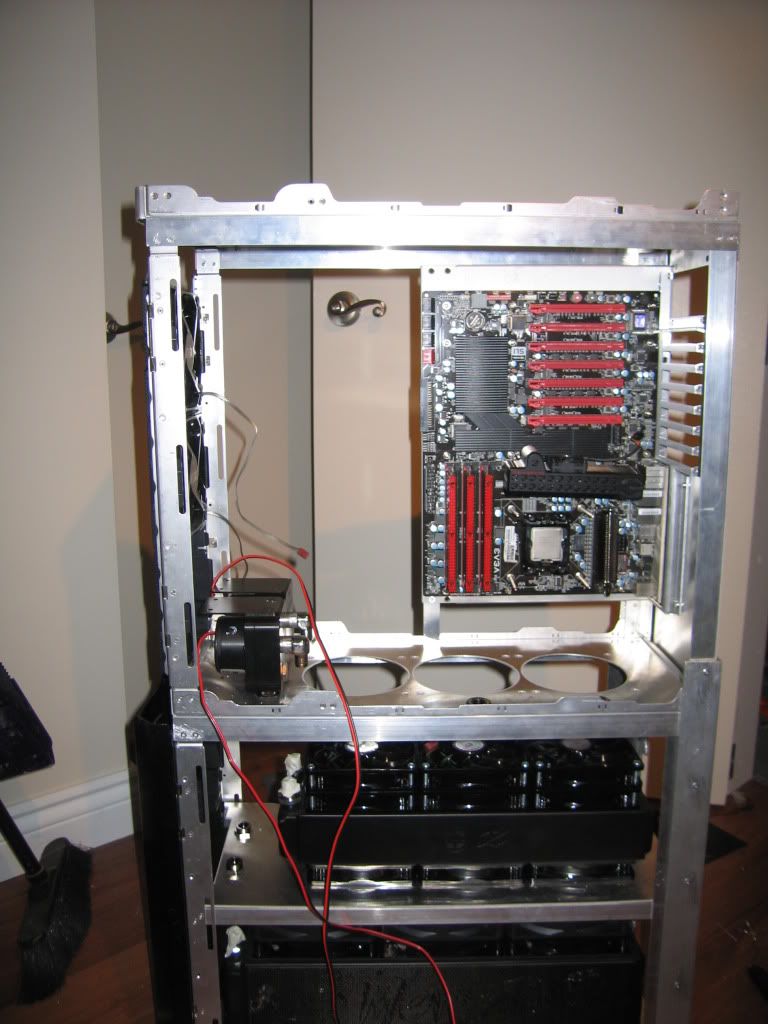

latest state of the build

VOTE FOR MY MODRIGS SETUP - CLICK THE LINK AND IF YOU LIKE THE SYSTEM, GIVE ME A +1

www.evga.com/ModsRigs/detail.aspx?BuildID=23510

Hi All

this is my first post to any forum, and 3rd attemp on here, stupid thing keeps deleting my post, ugh, bang head, bang head!!!

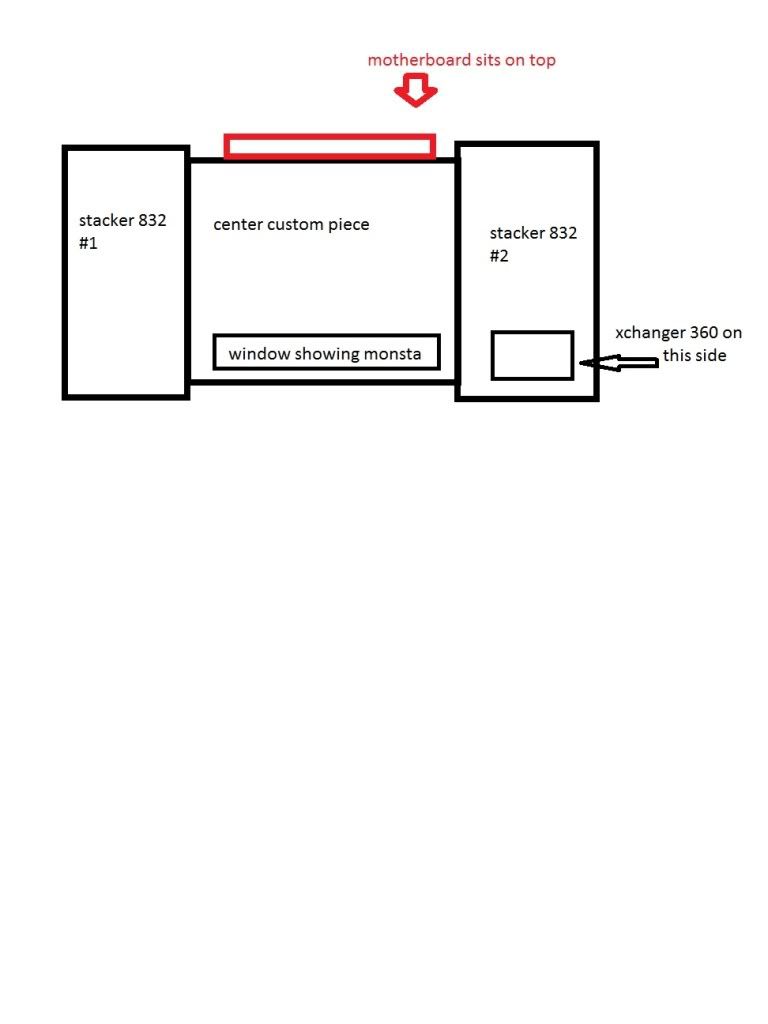

well im going to start off by saying this is a post for the build log of my new custome case/system which im calling FERMI 2

It was supposed to be called FERMI 3 but i sold off my FTW 480 today (money constaints).

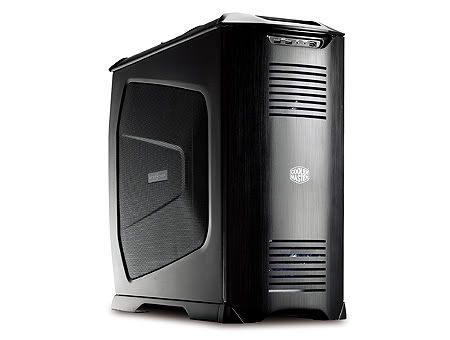

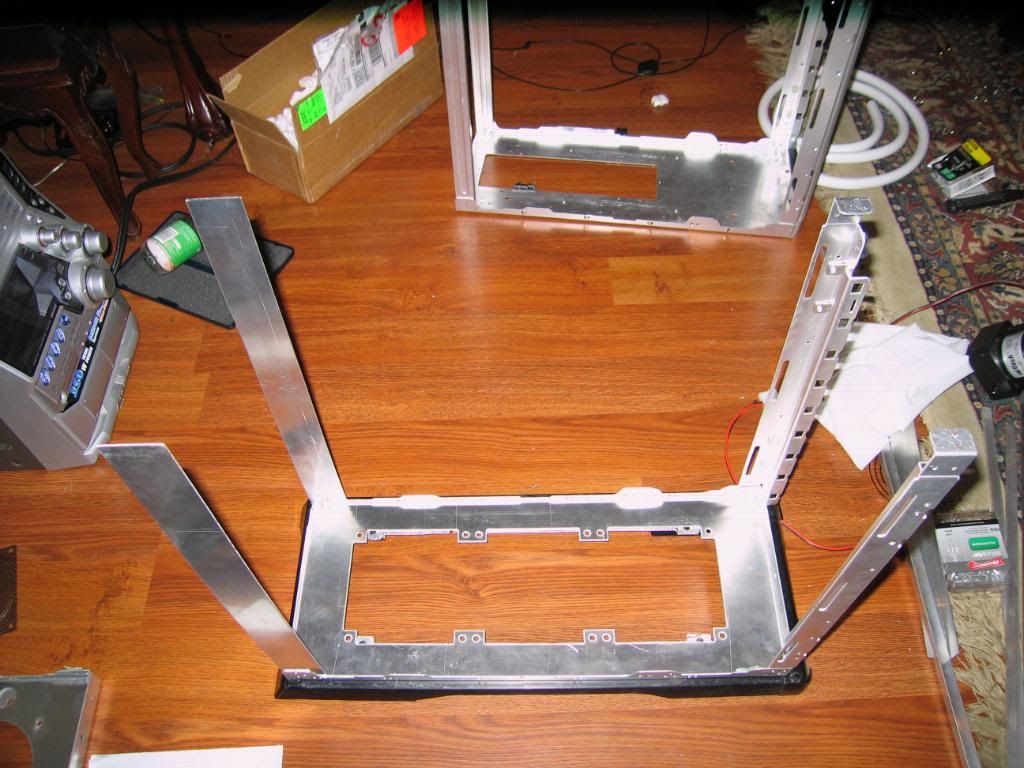

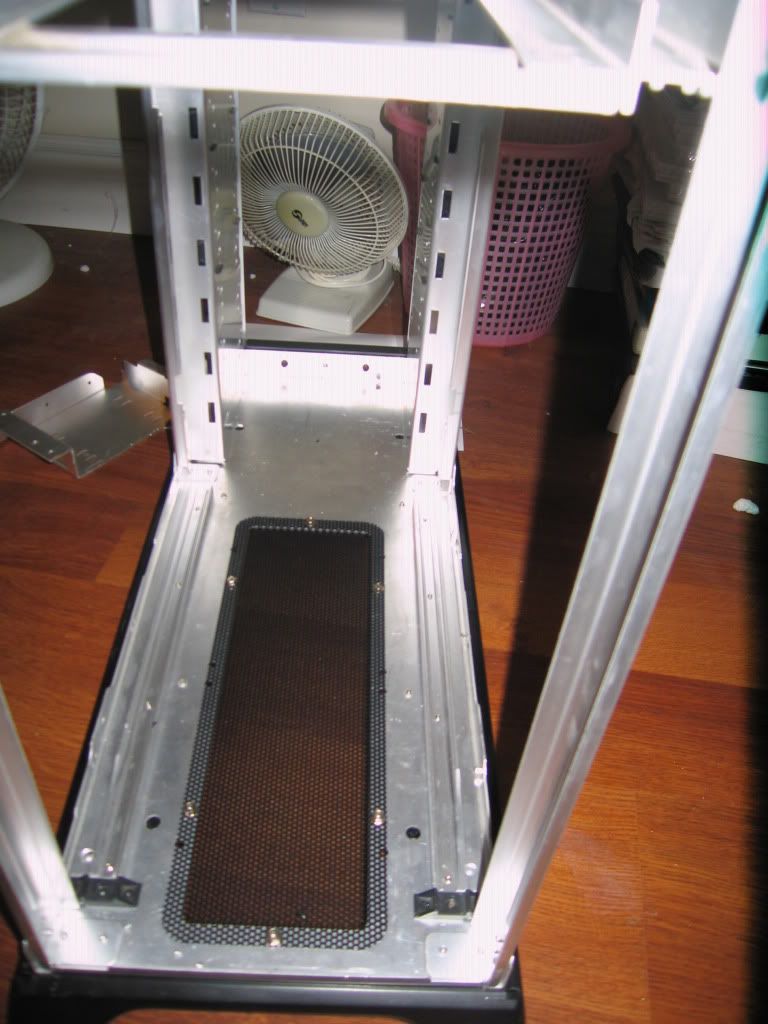

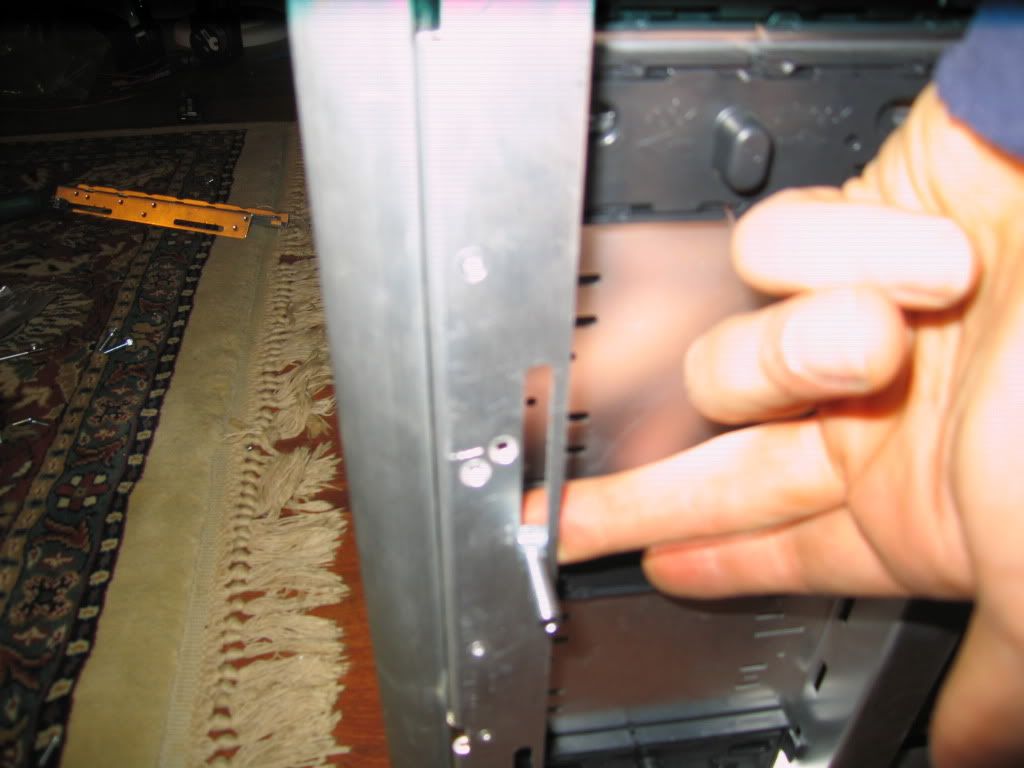

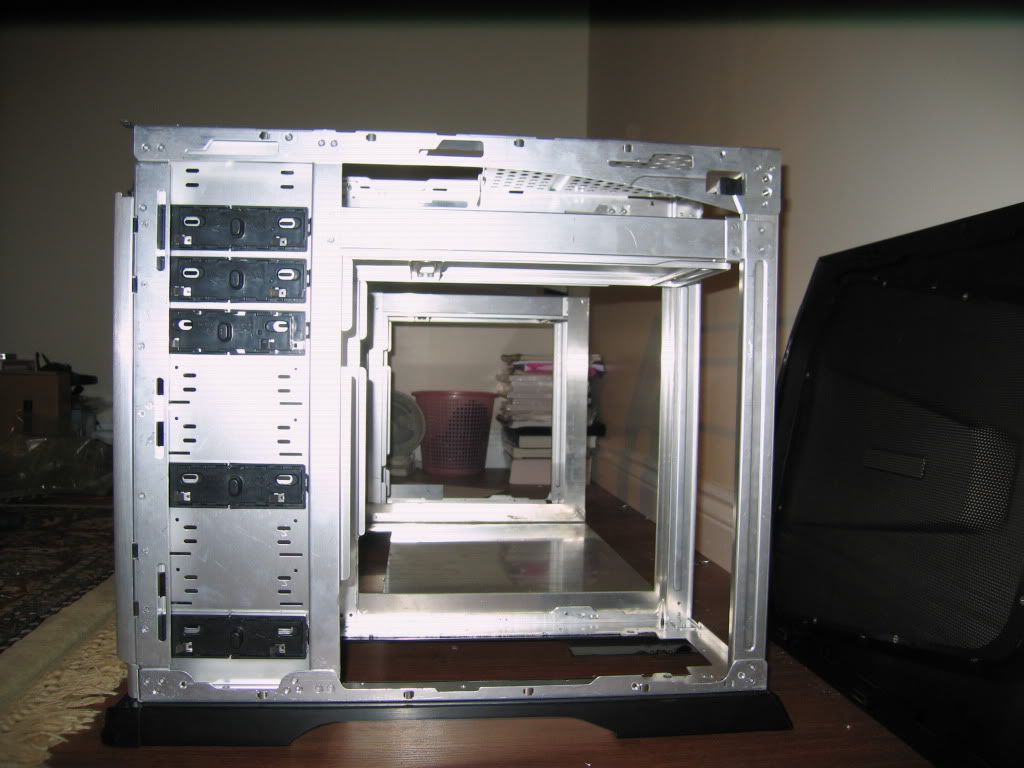

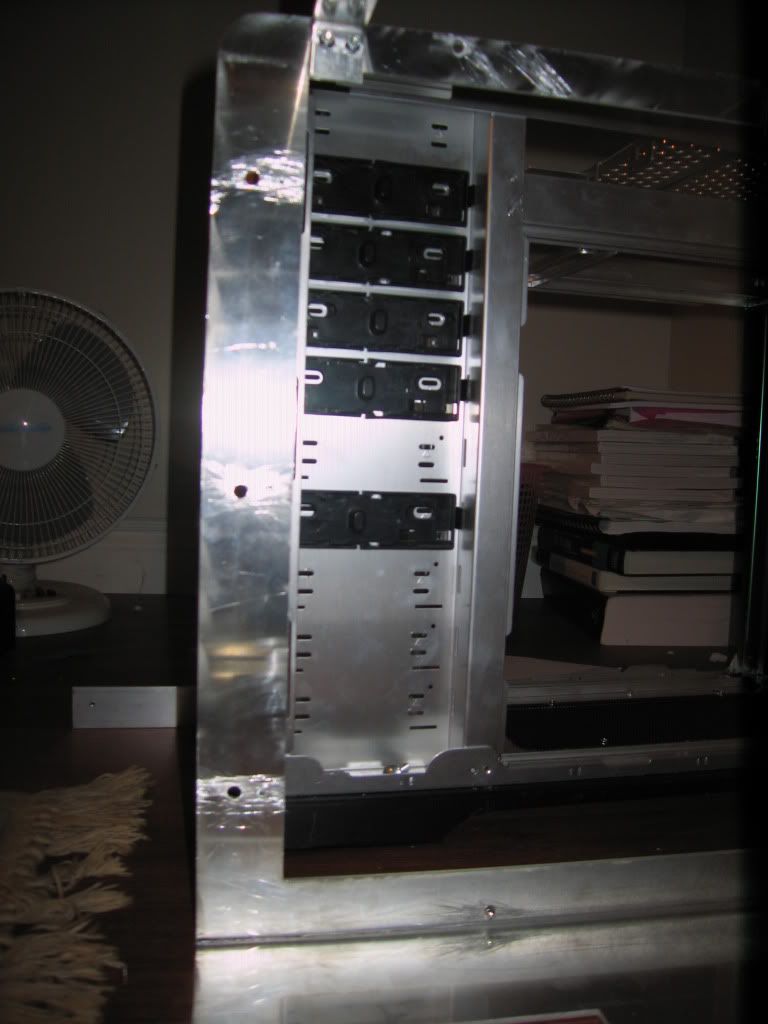

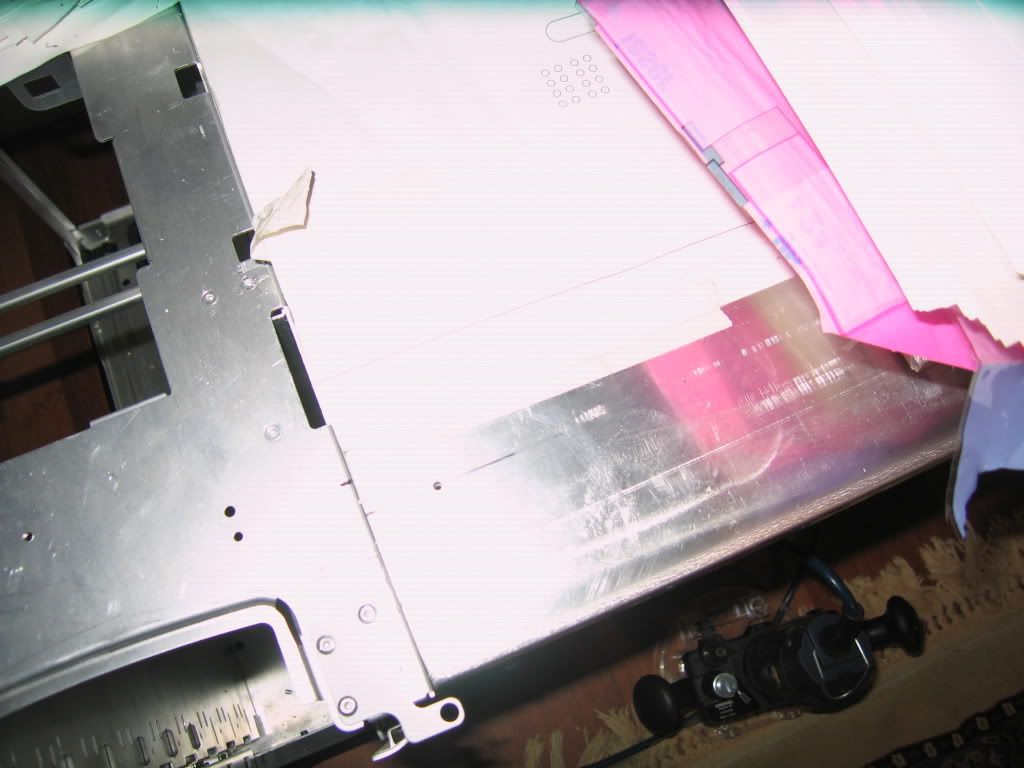

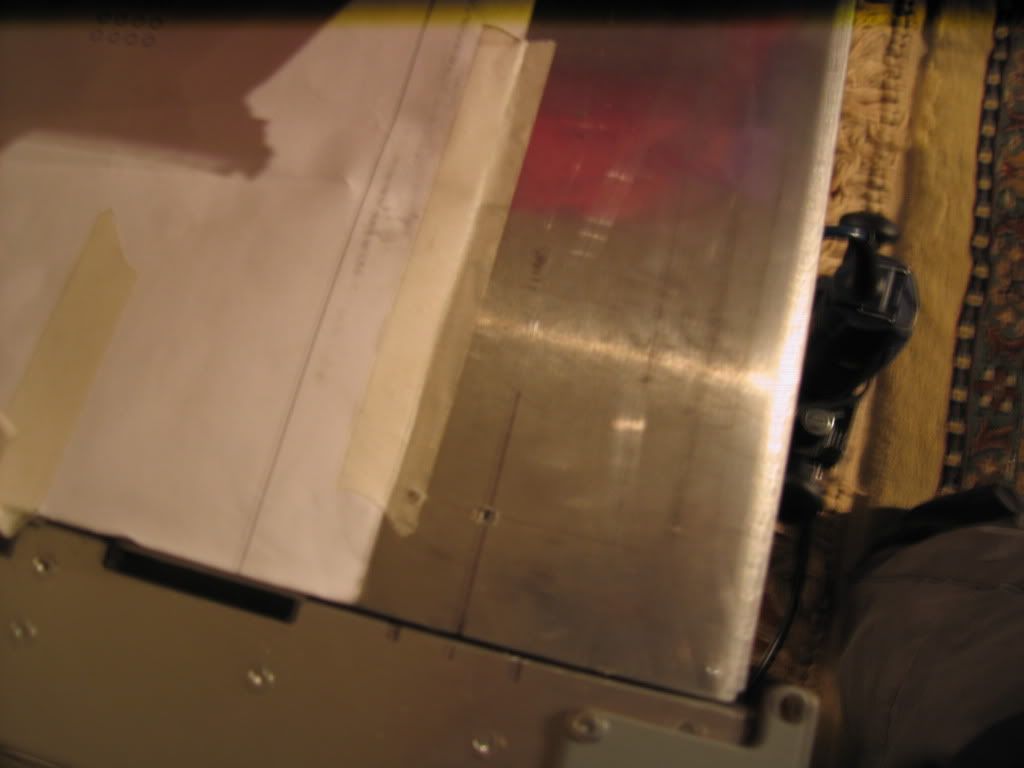

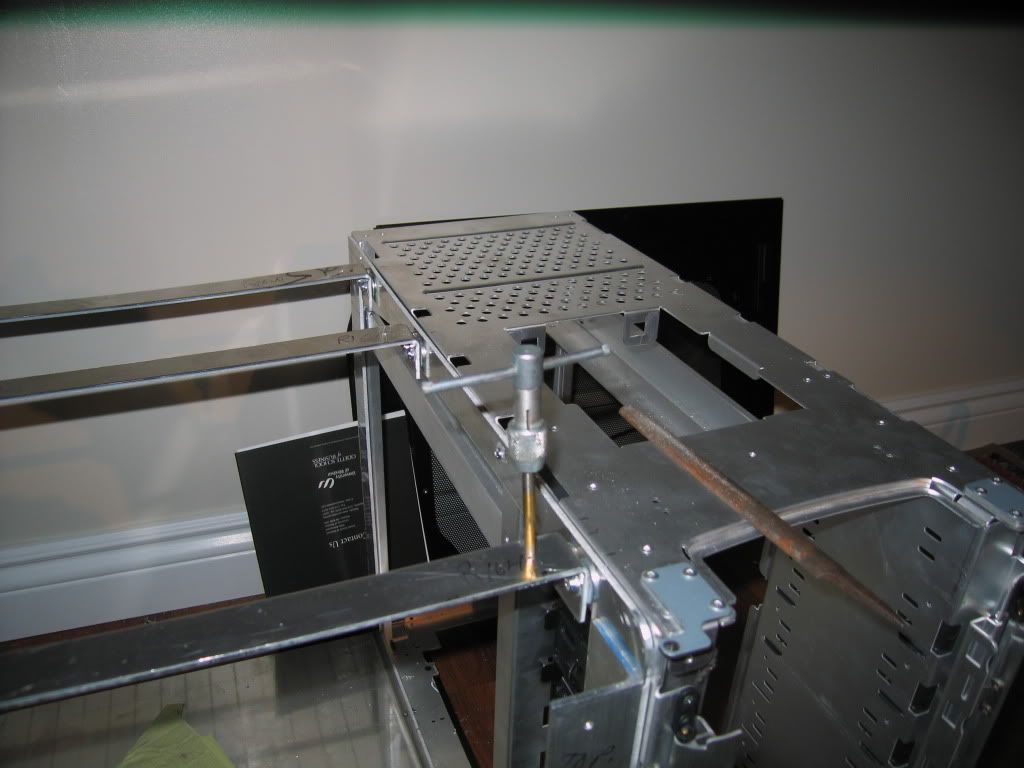

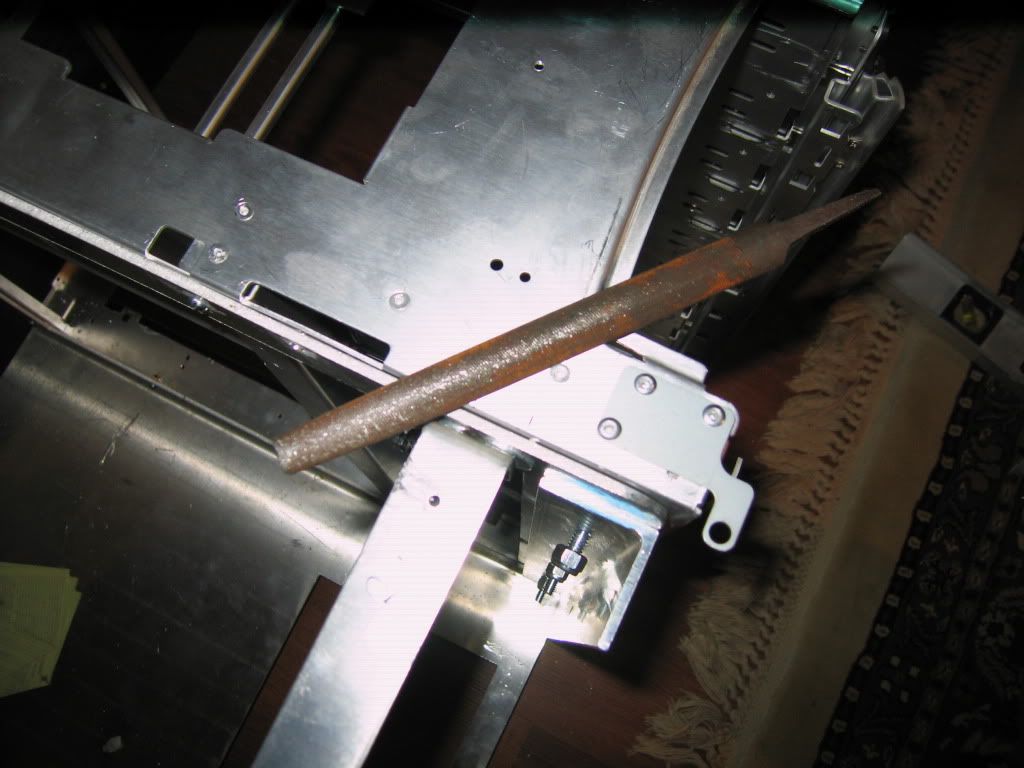

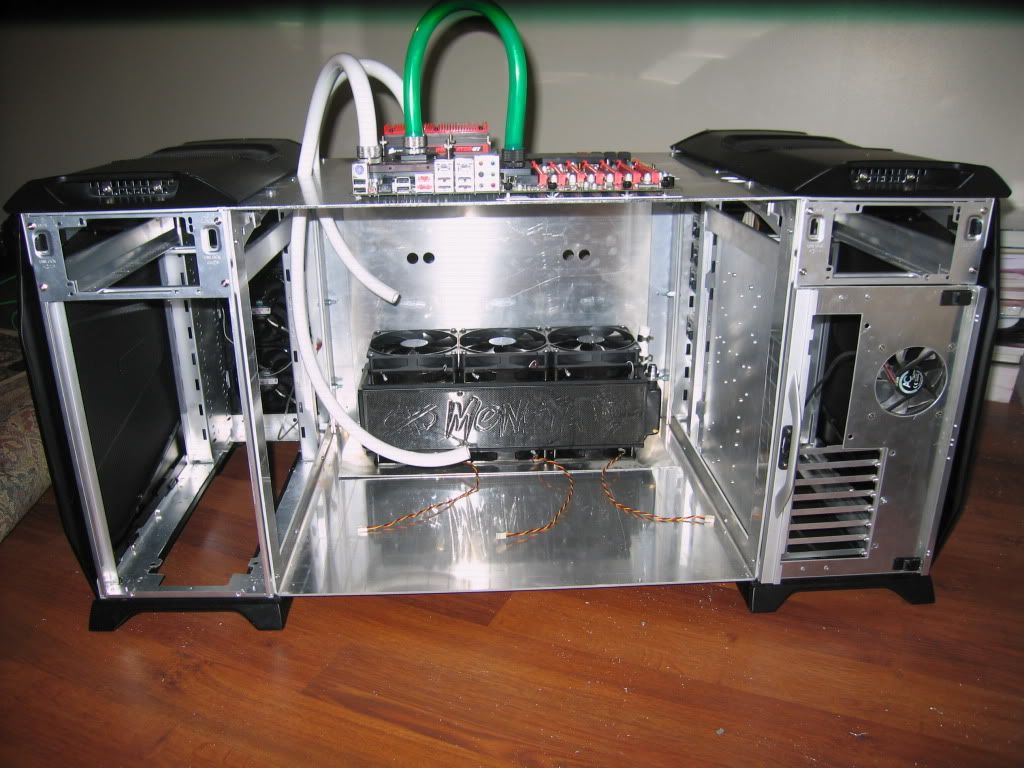

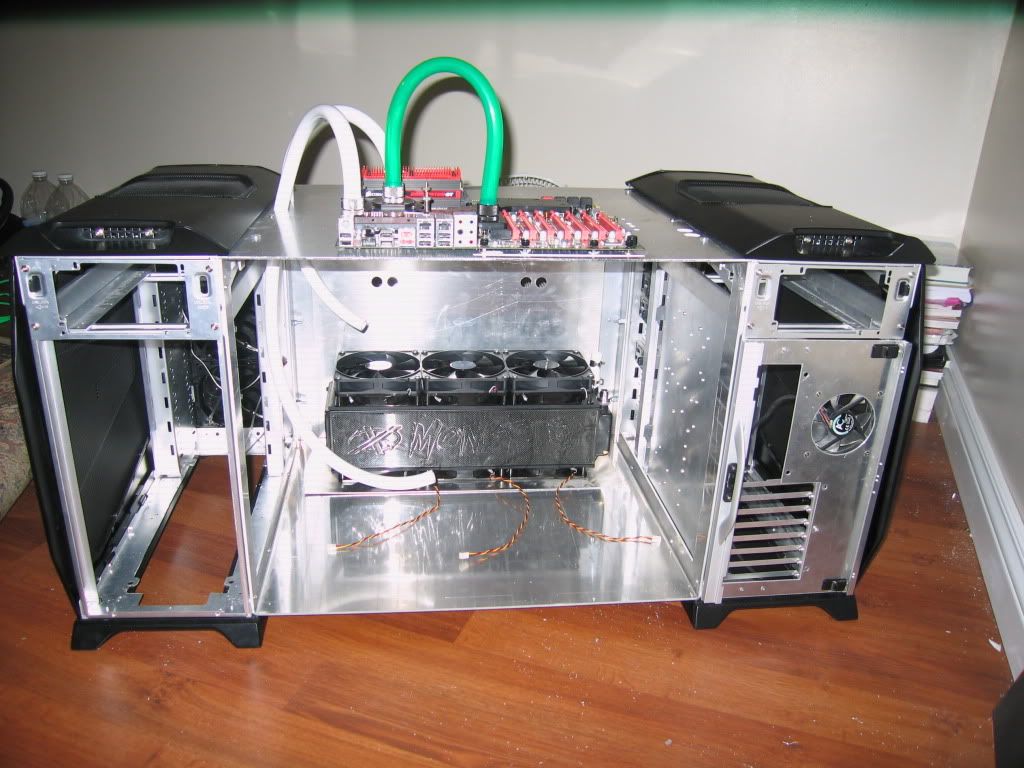

the case is made out of 2 coolermaster stacker 832 cases which i think you guys will like

which i think you guys will like

I have went through many revisions of this case and now have finally found one i like and that works well which is REV 4 right now

WHY I CHOSE TO CALL MY SYSTEM/CASE FERMI 2

Fermi is the name of a Nuclear power plant. I live in Windsor, Ontario Canada which is located across from Detroit, Michigan. Now there is an actually power plant near windsor and detroit (10-20 miles away) called FERMI 2. Its a nuclear power plant

since each gtx 480 is from the Fermi Family, I decided to call it FERMI 2. Ill be using 2 corsair 850w power supplies (2 generators), so Ill be putting 1700W or 1.7kW Capacity on the case maybe with red leds behind an engraved acrylic panel

maybe with red leds behind an engraved acrylic panel

Now if i decide to buy a 3rd GTX 480 (just sold my third one ... ) than ill be naming it FERMI 3.

... ) than ill be naming it FERMI 3.

Now there are 2 Fermi Cards (reactors), 2 cooling towers (2 radiators), 2 dump tanks (used for emergencies) (2 reservoirs), the the whole theme goes well with the case.

Let me know what you think.....

so

the system consists of the following:

Hardware:

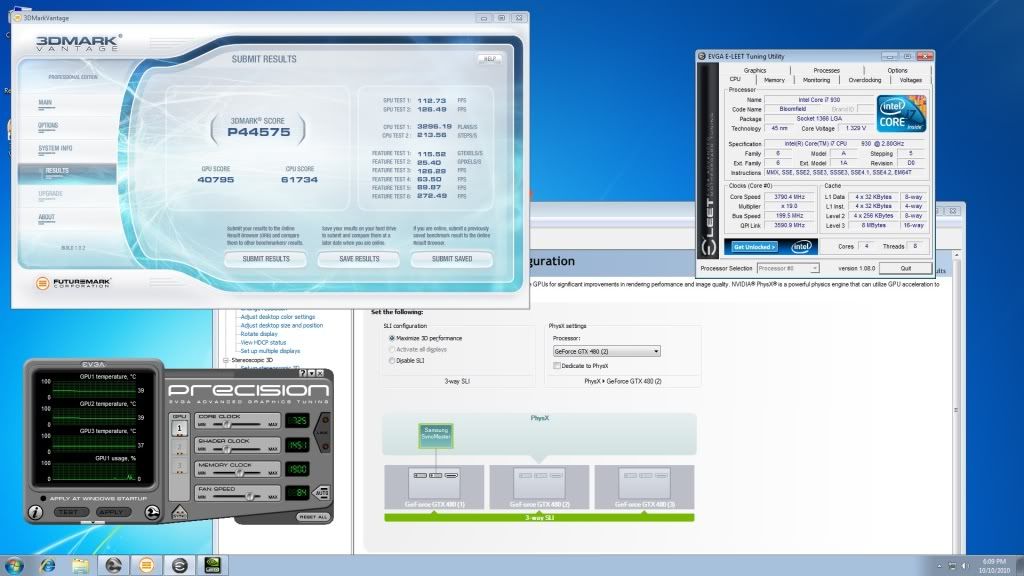

Core i7 930

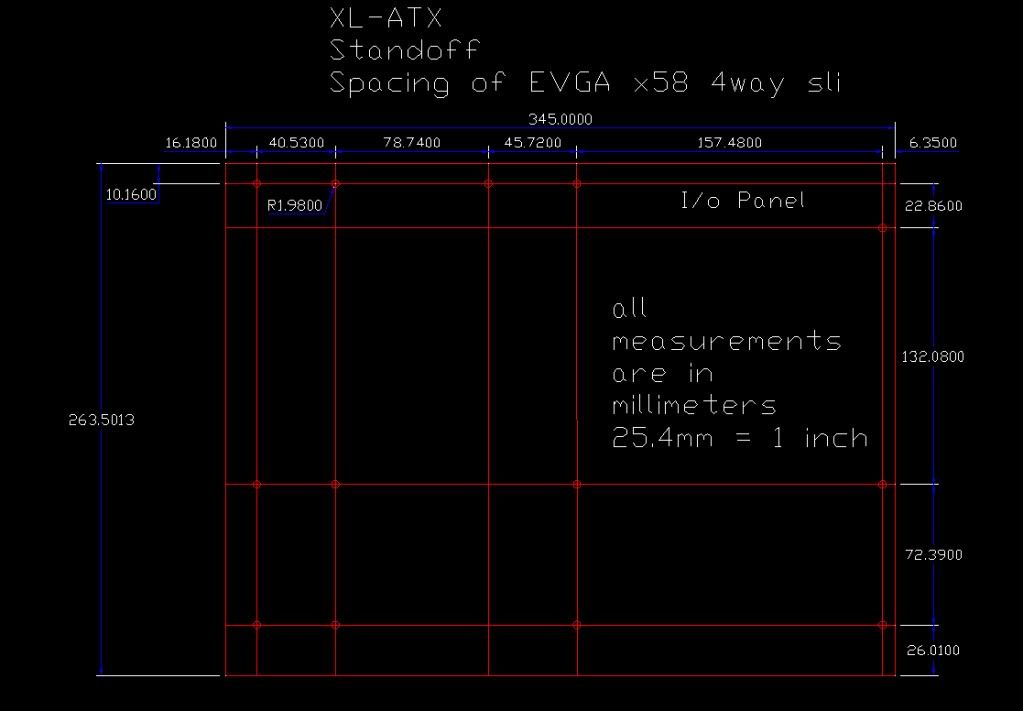

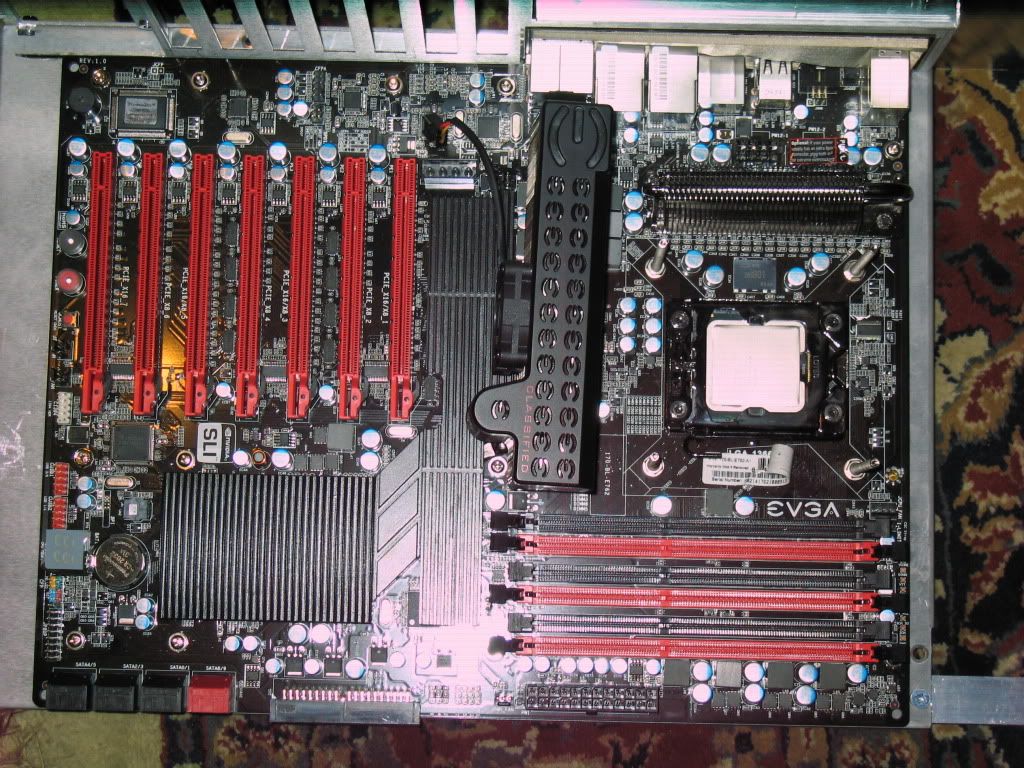

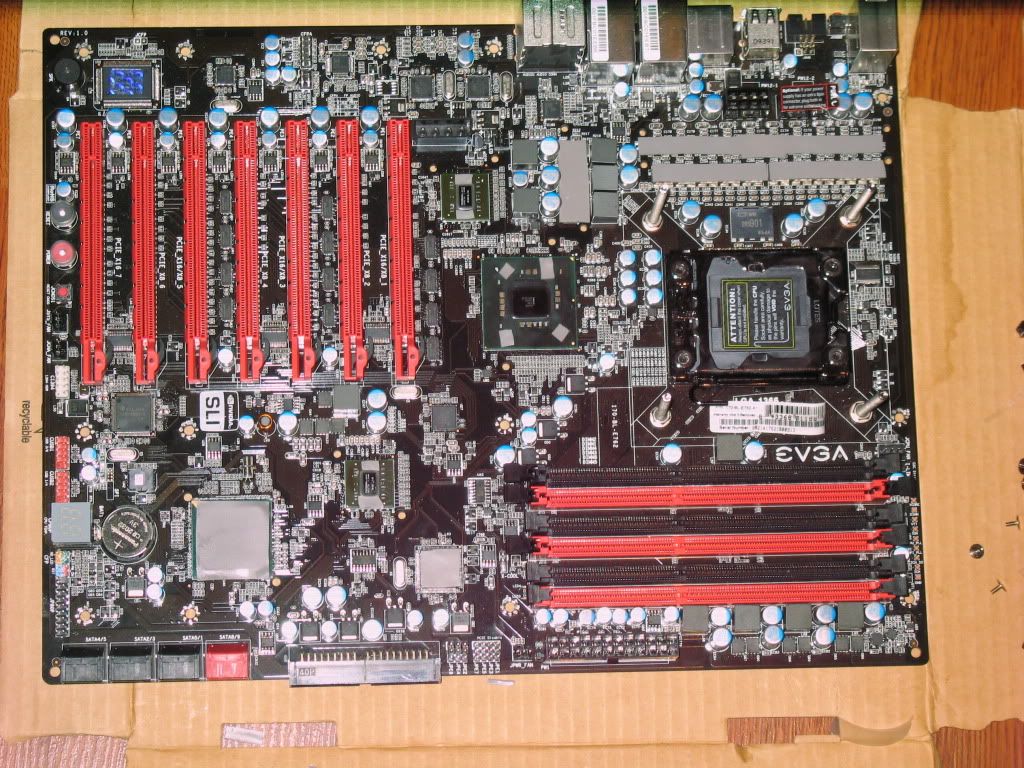

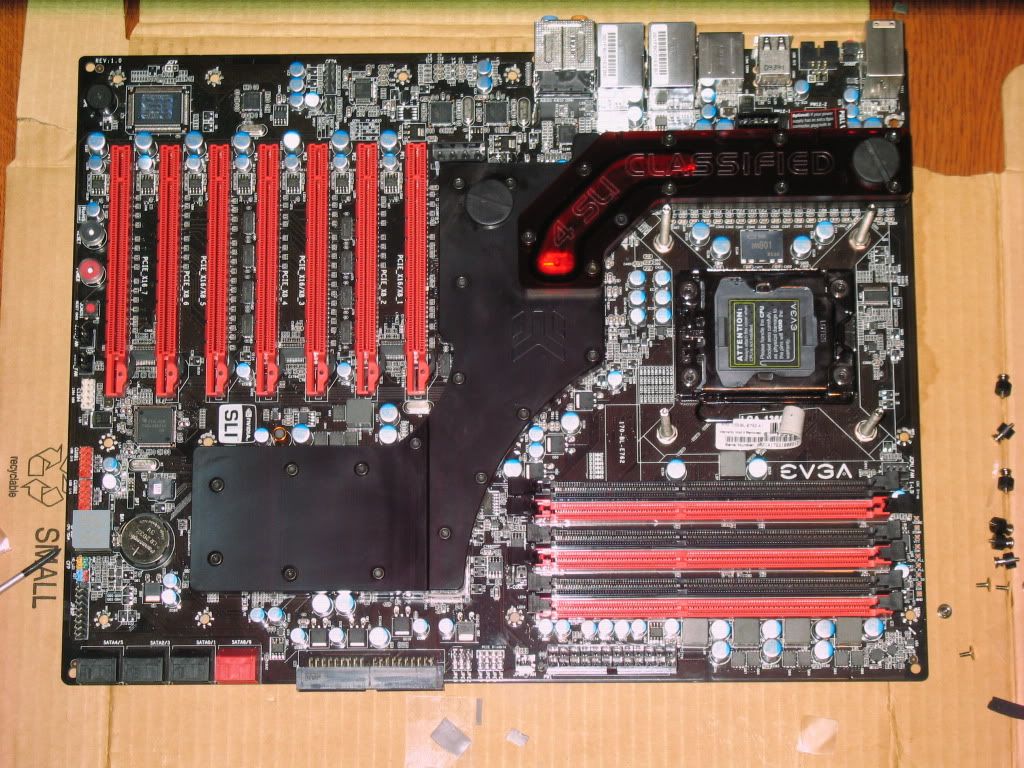

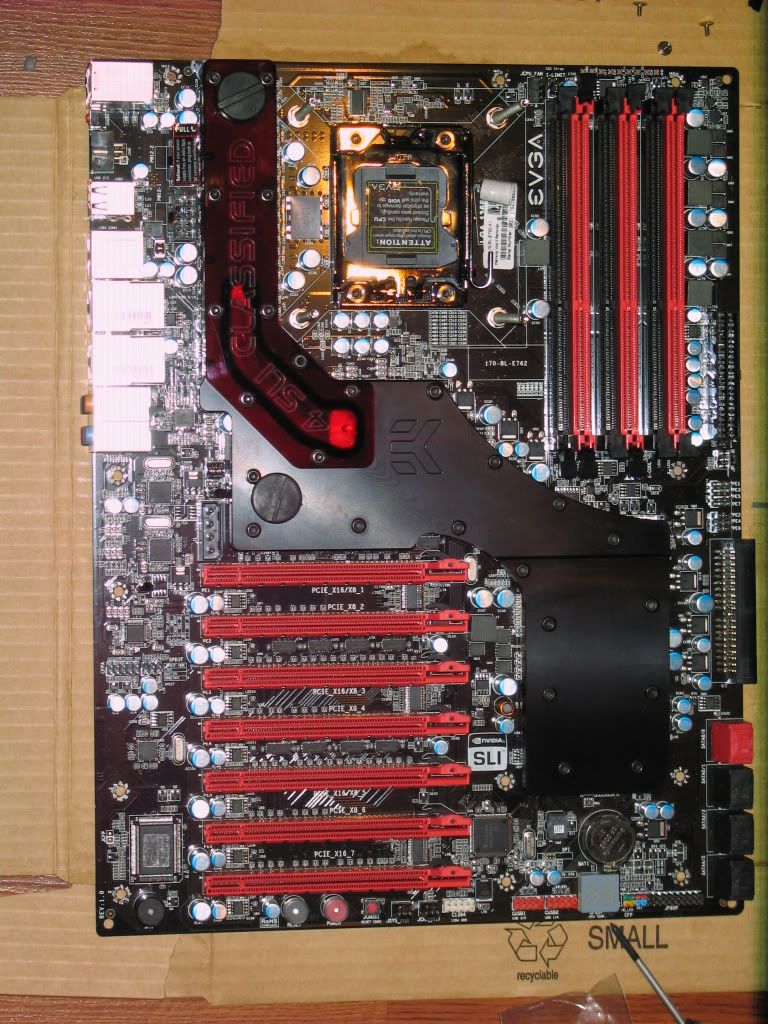

EVGA X58 4 way sli Mobo

Corsair Dominator GT 2000c7

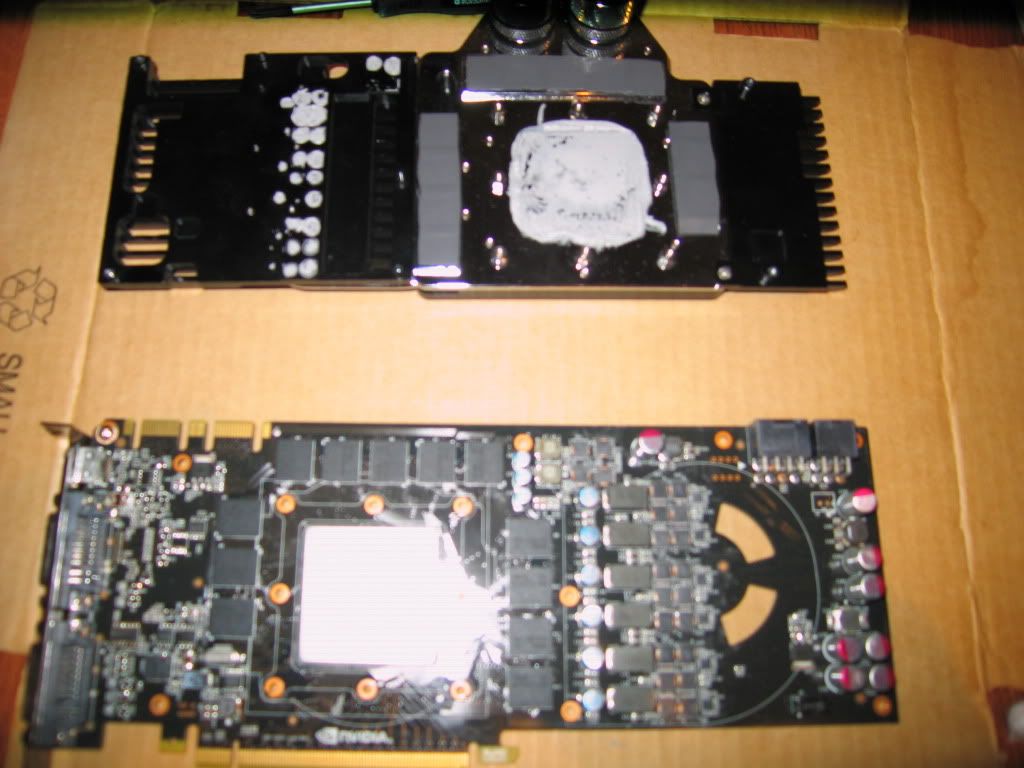

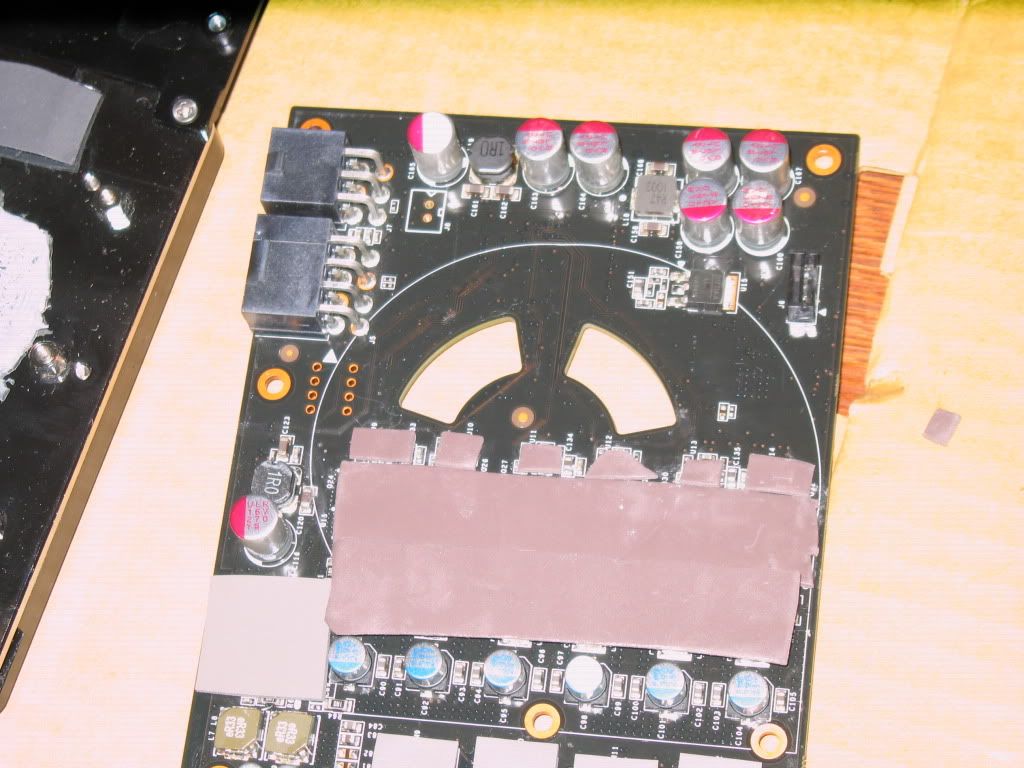

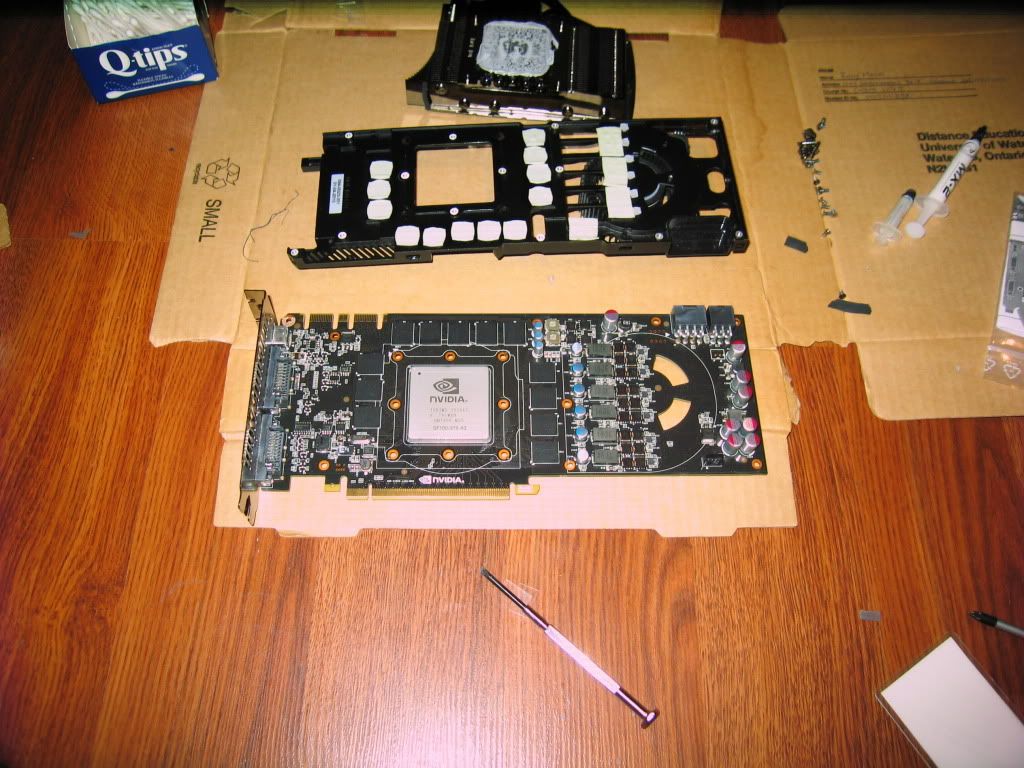

2 - EVGA GTX 480's Super Clocked editions

1 - Corsair HX850w power supply

1 - Corsair AX850w power supply (will get it in 2 weeks as i sold one of my two hx850's that was with my HD5970 build)

Watercooling:

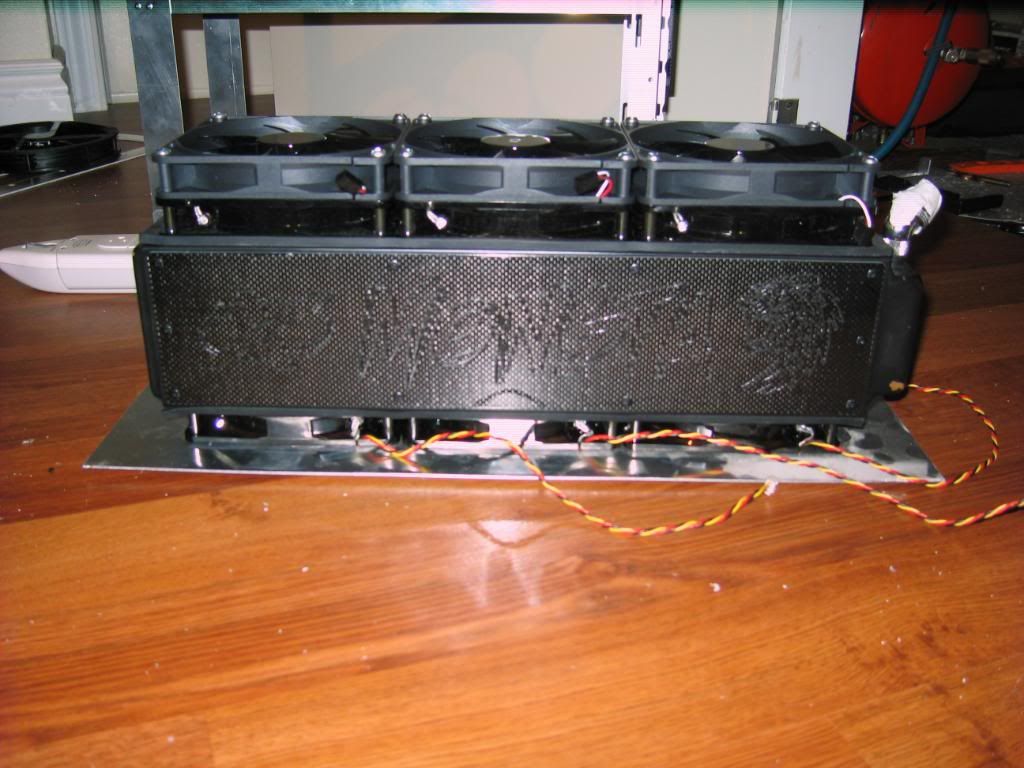

Feser 420 Monsta Radiator

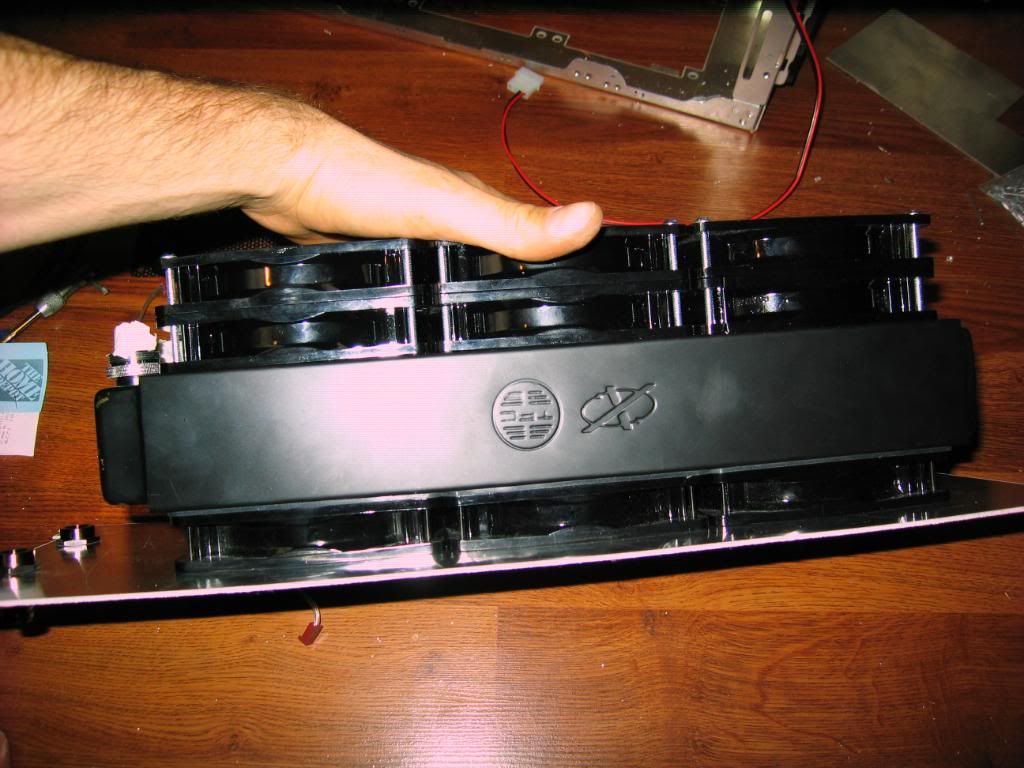

Feser 360 Xchanger Radiator

2 - Swiftech MCP-655 Pumps

2 - EK MCP-655 X-TOP Ver. 2

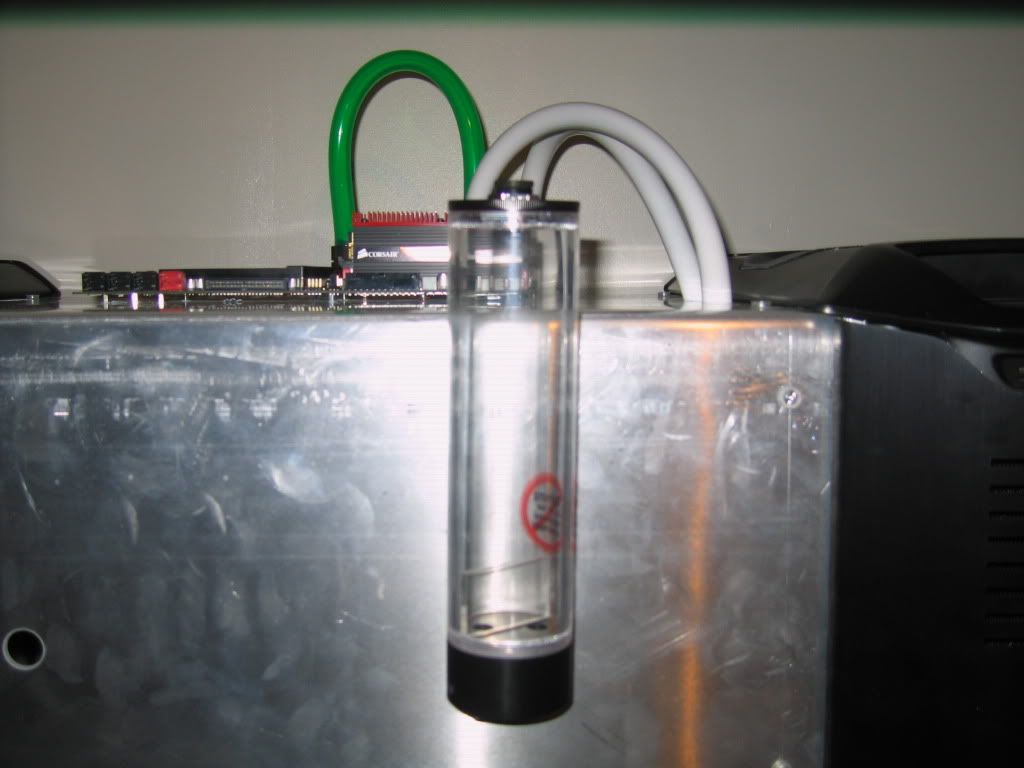

2 - Koolance 120mm Reservoirs

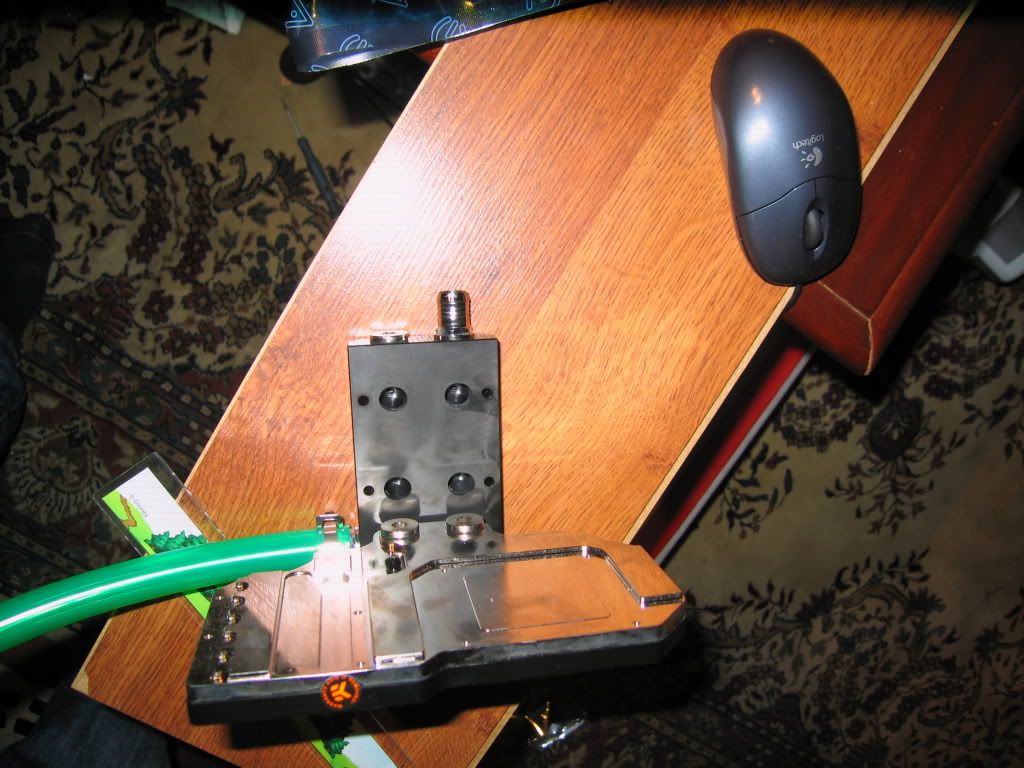

EK Supreme HF cpu block (black + nickel)

EK Classified 4 way Full Motherboard Block

MIPS computer Corsair 6 Ram Block

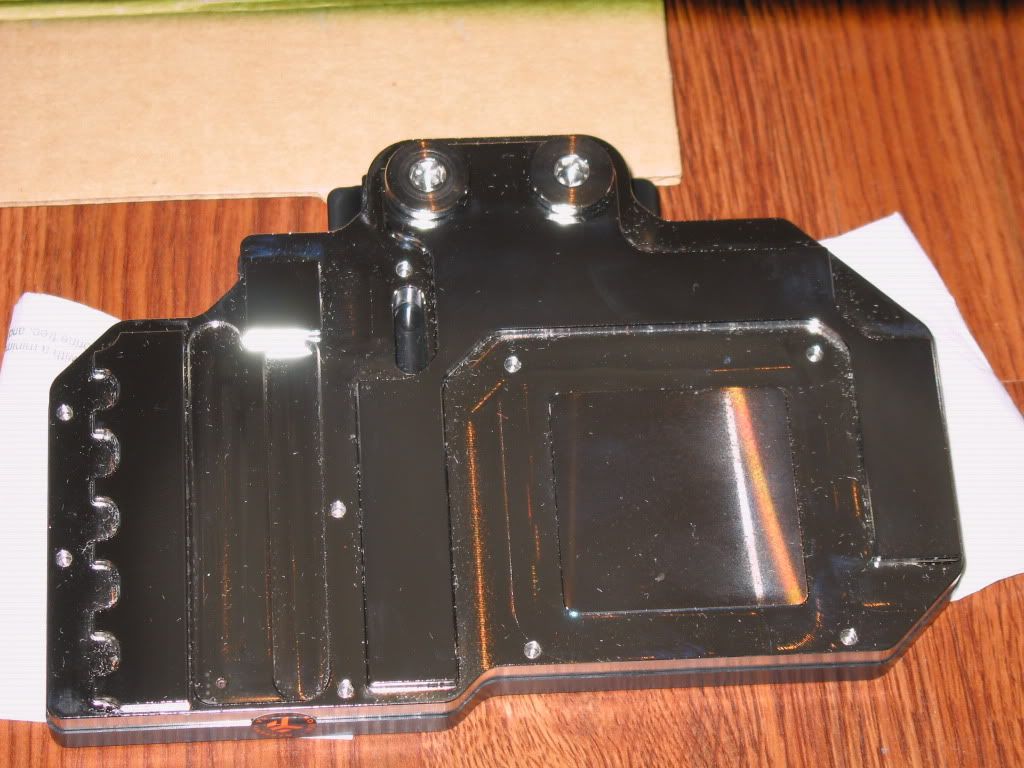

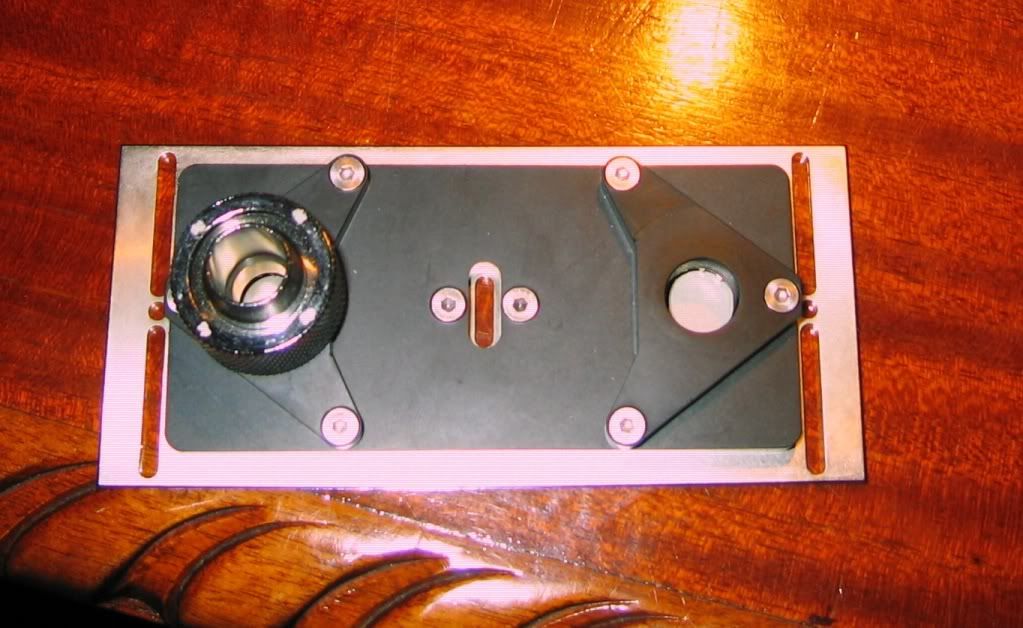

2 - Ek Nickel/POM GTX 480 Blocks

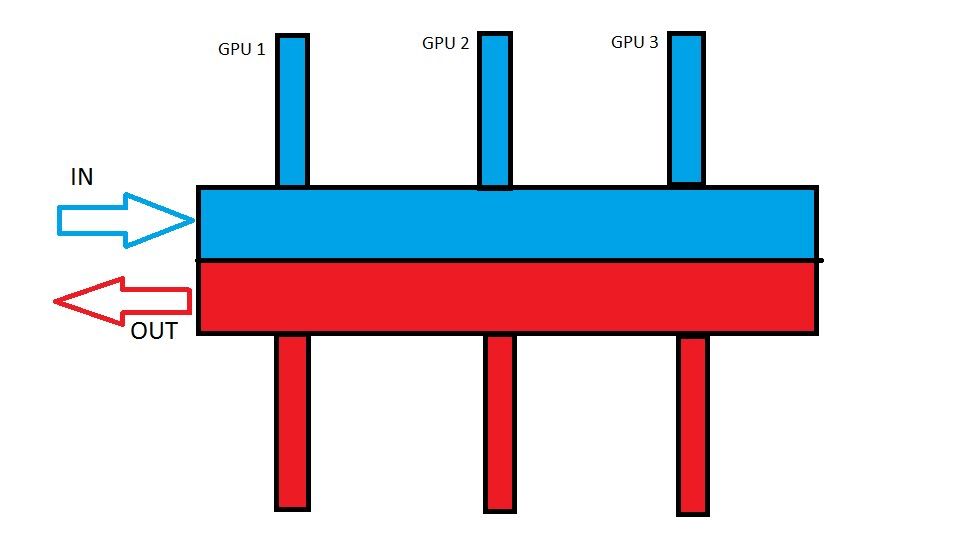

2 - EK GF200 LINKs

EK Triple Link Parallel

1/2" Promochill white tubing

1/2ID 3/4" OD Black Bitspower compression fittings (diff types and sizes)

Koolance TMS 200 and 200 expansion board

2 - Koolance Flow sensors INS-FM17

3 - Noise blocker PK-3 140mm Fans (1700rpm)

9 - Xigmatek 140mm fans 1000rpm (3 for pulling air, 6 used as shrouds)

4 - Antec 200mm Fans

9 - Coolermaster 120mm R4 Fans

Case:

2 - Coolermaster Stacker 832 Cases

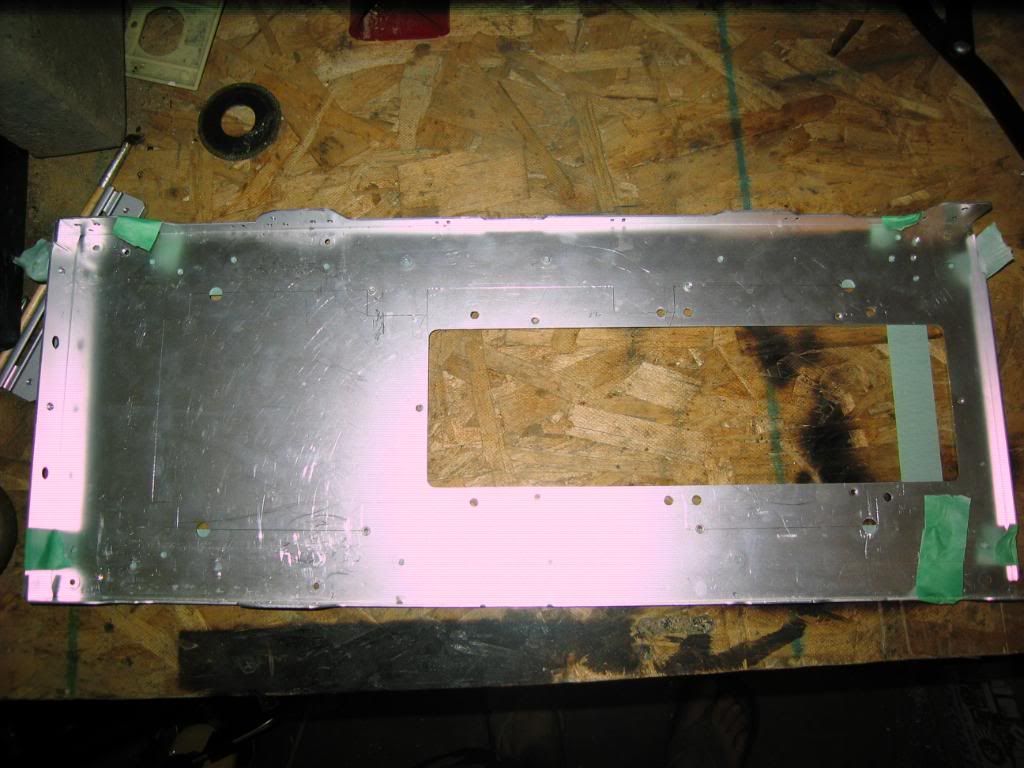

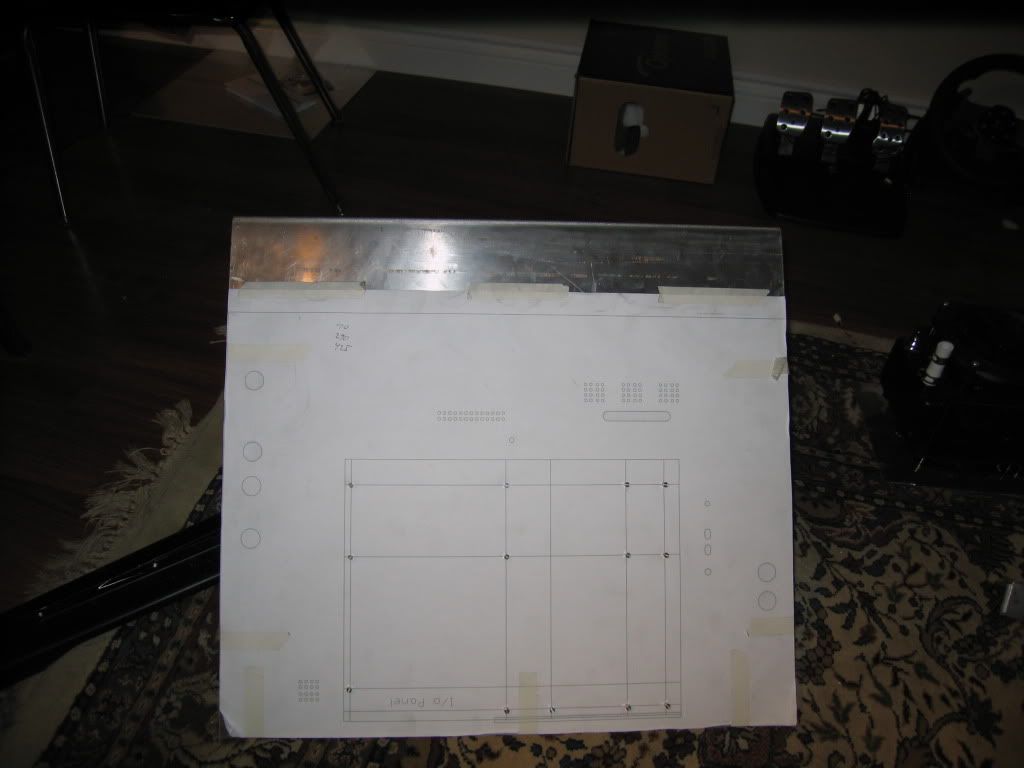

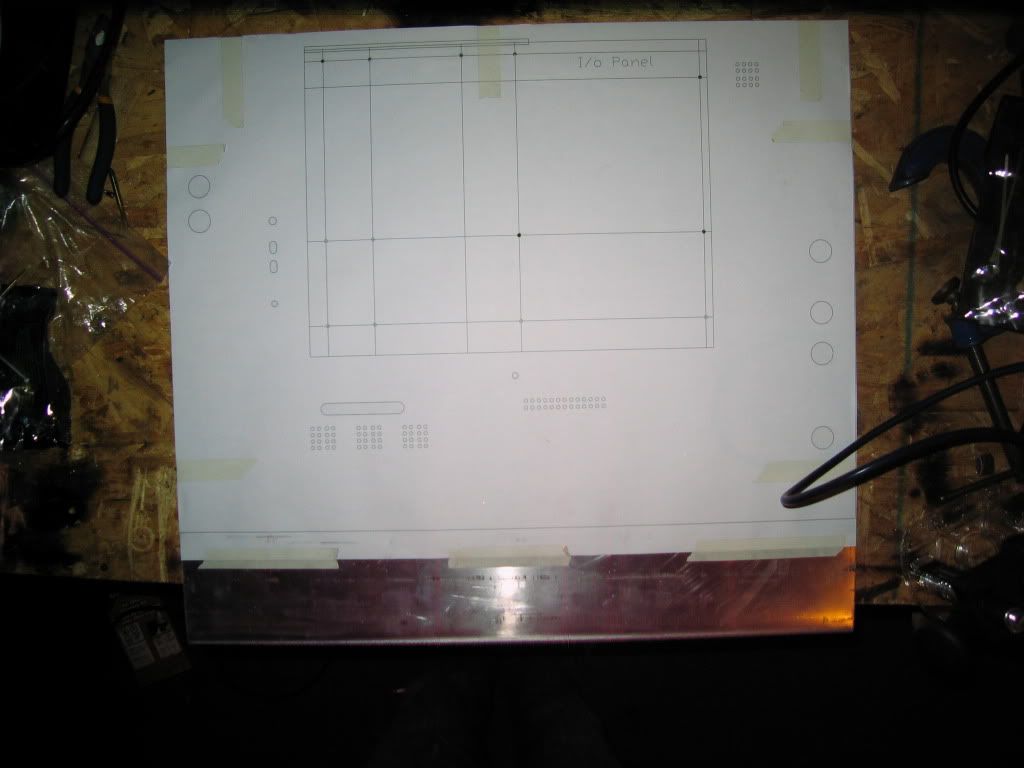

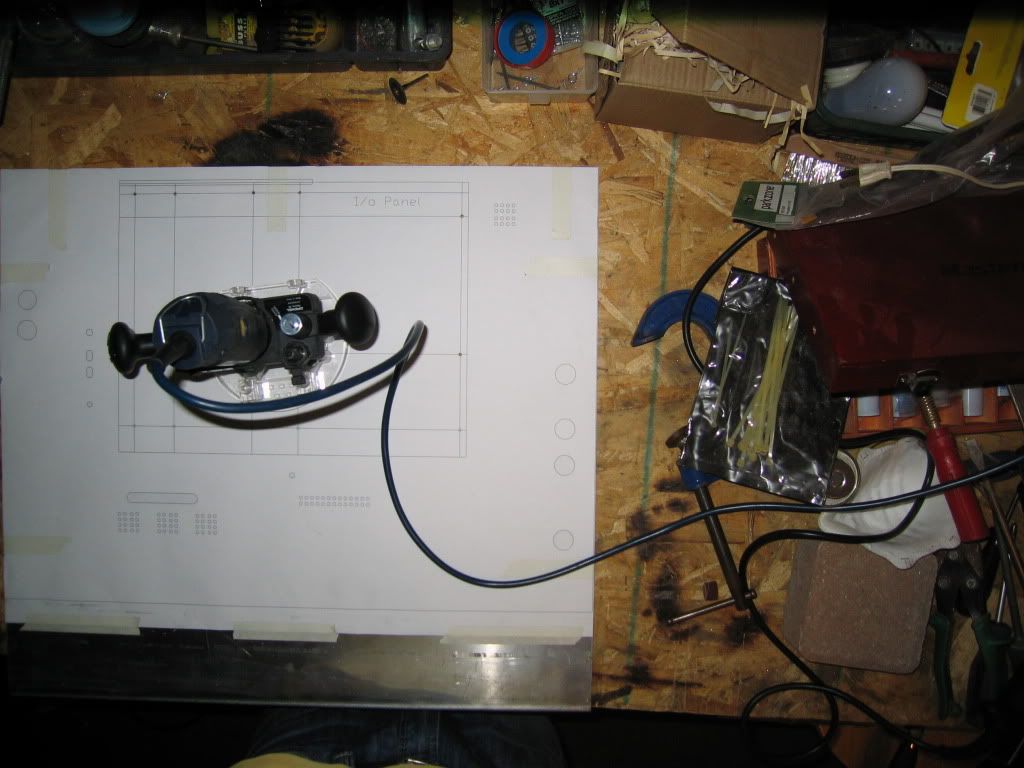

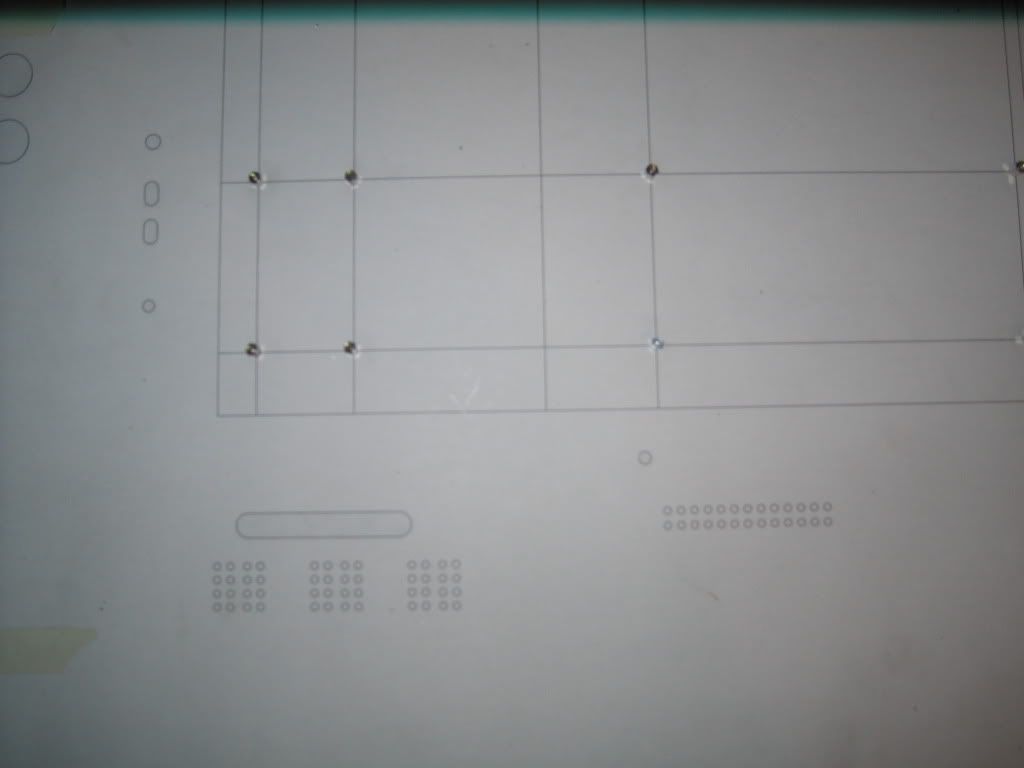

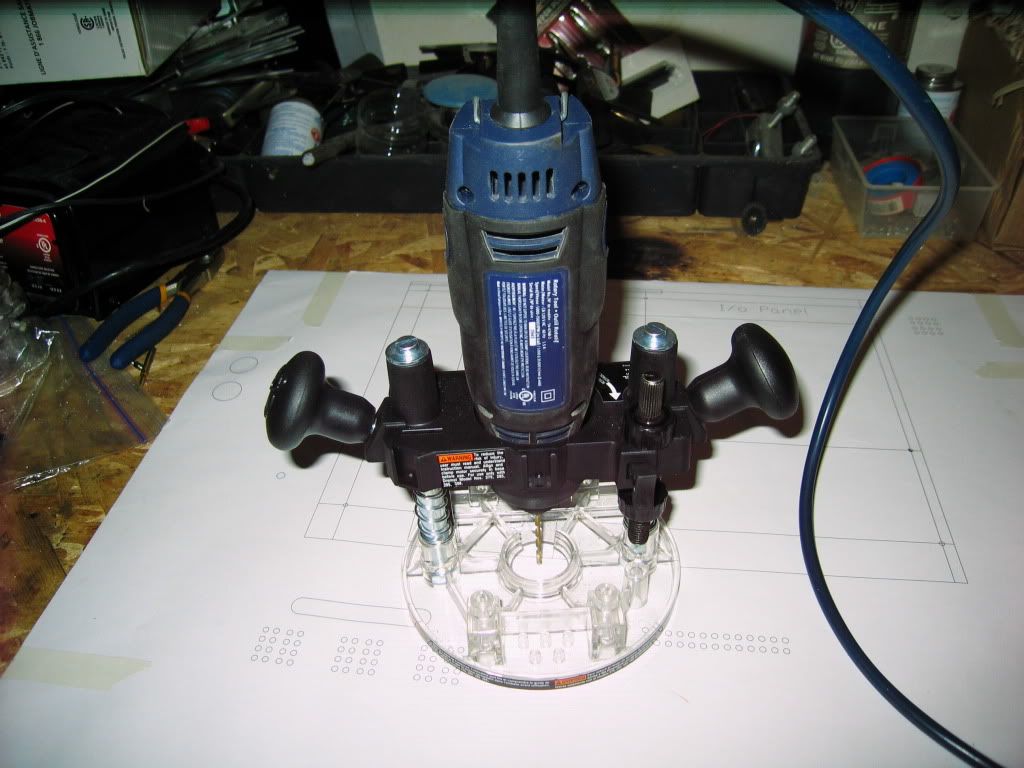

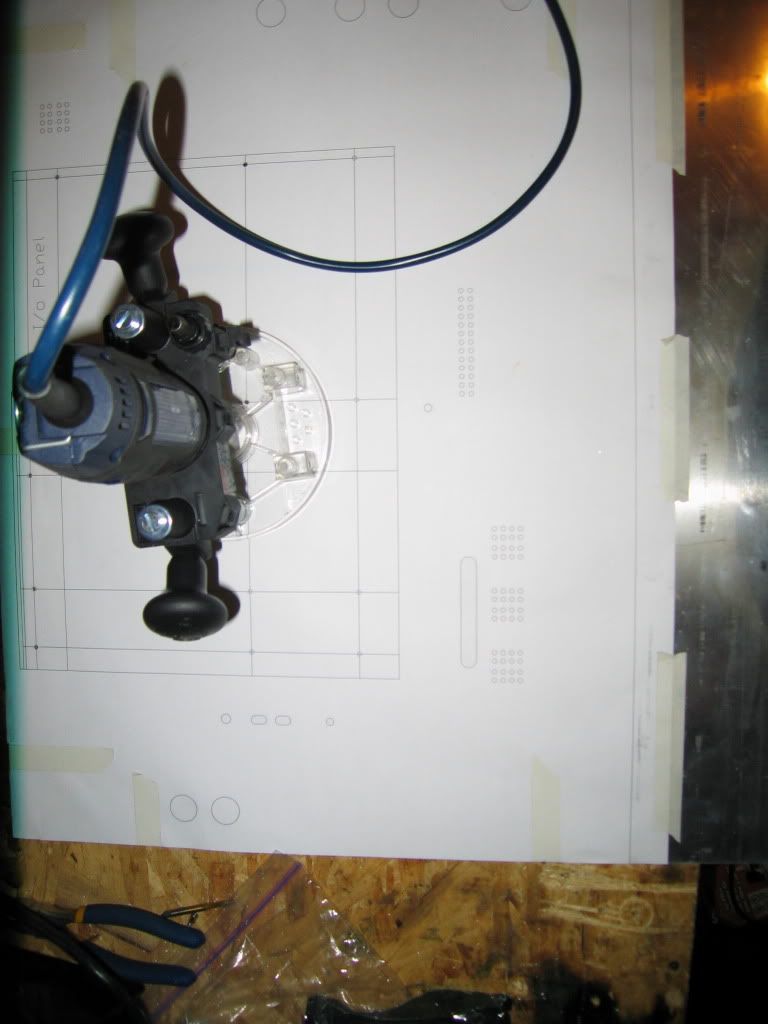

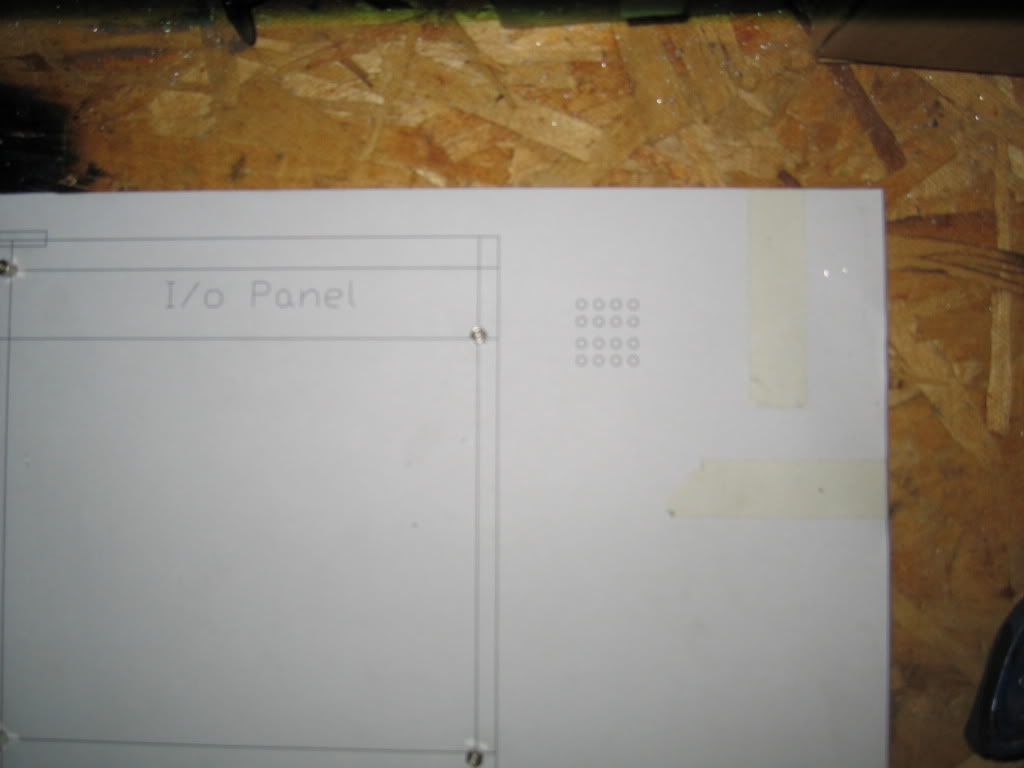

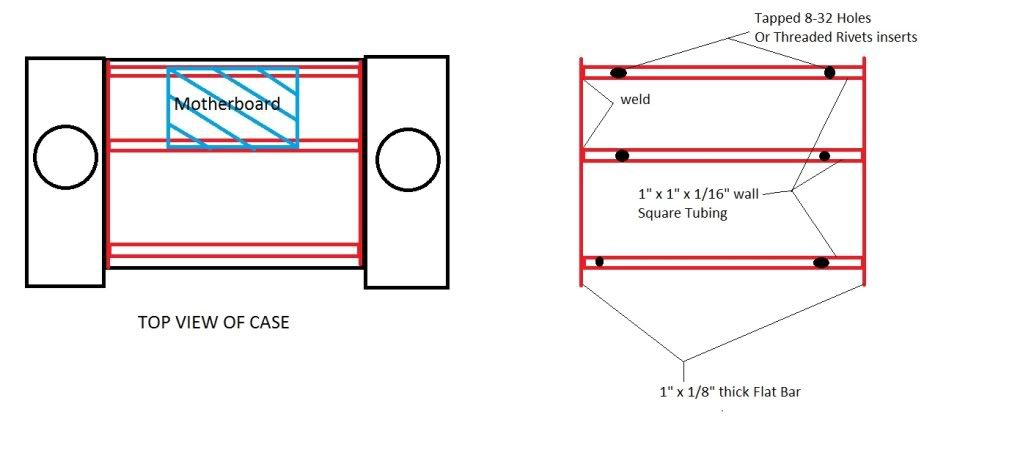

Custom waterjetted, bent and welded aluminum parts ( i will provide the CAD drawings for anyones use)

( i will provide the CAD drawings for anyones use)

So thats the parts list for now, I am thinking of some editions with regards to sound card, low power vid card, usb 3.0 cards as well but I will post about those at a later date when the time is right

stay tuned, and i would appreciate your comments and insight

cheers

You can visit my entire post on EVGA FORUM - http://www.evga.com/forums/tm.aspx?high=&m=602083&mpage=1#602083

latest state of the build

VOTE FOR MY MODRIGS SETUP - CLICK THE LINK AND IF YOU LIKE THE SYSTEM, GIVE ME A +1

www.evga.com/ModsRigs/detail.aspx?BuildID=23510

Hi All

this is my first post to any forum, and 3rd attemp on here, stupid thing keeps deleting my post, ugh, bang head, bang head!!!

well im going to start off by saying this is a post for the build log of my new custome case/system which im calling FERMI 2

It was supposed to be called FERMI 3 but i sold off my FTW 480 today (money constaints).

the case is made out of 2 coolermaster stacker 832 cases

I have went through many revisions of this case and now have finally found one i like and that works well which is REV 4 right now

WHY I CHOSE TO CALL MY SYSTEM/CASE FERMI 2

Fermi is the name of a Nuclear power plant. I live in Windsor, Ontario Canada which is located across from Detroit, Michigan. Now there is an actually power plant near windsor and detroit (10-20 miles away) called FERMI 2. Its a nuclear power plant

since each gtx 480 is from the Fermi Family, I decided to call it FERMI 2. Ill be using 2 corsair 850w power supplies (2 generators), so Ill be putting 1700W or 1.7kW Capacity on the case

Now if i decide to buy a 3rd GTX 480 (just sold my third one

Now there are 2 Fermi Cards (reactors), 2 cooling towers (2 radiators), 2 dump tanks (used for emergencies) (2 reservoirs), the the whole theme goes well with the case.

Let me know what you think.....

so

the system consists of the following:

Hardware:

Core i7 930

EVGA X58 4 way sli Mobo

Corsair Dominator GT 2000c7

2 - EVGA GTX 480's Super Clocked editions

1 - Corsair HX850w power supply

1 - Corsair AX850w power supply (will get it in 2 weeks as i sold one of my two hx850's that was with my HD5970 build)

Watercooling:

Feser 420 Monsta Radiator

Feser 360 Xchanger Radiator

2 - Swiftech MCP-655 Pumps

2 - EK MCP-655 X-TOP Ver. 2

2 - Koolance 120mm Reservoirs

EK Supreme HF cpu block (black + nickel)

EK Classified 4 way Full Motherboard Block

MIPS computer Corsair 6 Ram Block

2 - Ek Nickel/POM GTX 480 Blocks

2 - EK GF200 LINKs

EK Triple Link Parallel

1/2" Promochill white tubing

1/2ID 3/4" OD Black Bitspower compression fittings (diff types and sizes)

Koolance TMS 200 and 200 expansion board

2 - Koolance Flow sensors INS-FM17

3 - Noise blocker PK-3 140mm Fans (1700rpm)

9 - Xigmatek 140mm fans 1000rpm (3 for pulling air, 6 used as shrouds)

4 - Antec 200mm Fans

9 - Coolermaster 120mm R4 Fans

Case:

2 - Coolermaster Stacker 832 Cases

Custom waterjetted, bent and welded aluminum parts

So thats the parts list for now, I am thinking of some editions with regards to sound card, low power vid card, usb 3.0 cards as well but I will post about those at a later date when the time is right

stay tuned, and i would appreciate your comments and insight

cheers

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)